Lighting it up with high-power LED drivers

High-power LEDs now in production have hit 100 lumens/W in output, a level considered a critical milestone. Some manufacturers even claim they get 120 lumens/W in the laboratory. This means the LED has now surpassed the CFL (80 lumens/W) in terms of energy efficiency. And LED technology isn't done: Expectations are that by 2012, LEDs will attain150 lumens/W output.

The cost of LED lighting has been dropping quickly. Much of the cost of a typical LED bulb is accounted for by the individual white-light diodes it contains. These have come down in price from about $5 each a few years ago to less than $1 in the last twelve months. Many LED industry analysts predict that over the course of the next year, LED replacements for incandescent bulbs will hit prices that most consumers are willing to pay.

Some LED manufacturers already claim to have designed light-emitting chips able to power an LED bulb producing light comparable to that of 75-W incandescent bulbs commonly used in American homes. This type of LED chip usually consumes about 12 W of power when putting out this amount of light.

The chip that drives an illumination-grade LED today must be able to dim the LED light. LEDs are driven with a constant current, where the dc current level is proportional to LED brightness. There are two methods of dimming the LED by controlling its current. The first is analog dimming, in which the LED gets dimmer in proportion to a reduction of its dc current level. The main problem is that reducing the LED current can make the LED light change color.

The second method is digital or pulse-width-modulation (PWM) dimming. PWM dimming switches the LED on and off at a frequency at or above 100 Hz, a frequency not perceivable to the human eye. The PWM dimming duty cycle is proportional to LED brightness, while the on-time LED current remains at a level set by an LED driver IC. This action maintains a constant LED color even with significant dimming. This method of PWM dimming can be used with on/off ratios as high as 10,000:1 in certain applications.

The ICs that drive high-brightness (HB) LEDs must be capable of delivering enough current and voltage to handle many different types of LED configurations. LED illumination has evolved to a point where there are a number of features any driver IC for this market needs to provide. Most industry observers would probably agree that these features include a wide input voltage range that goes up to 100 V; a wide output voltage range also up to 100 V; a conversion efficiency in the range of 95%; tightly regulated LED current matching, probably less than 2% over temperature; an ability to operate with low noise at frequencies as high as 2.5 MHz; independent current and dimming control and wide dimming range ratios, up to 10,000: 1.

It has also become clear that LED drivers need to provide multiple conversion topologies that include buck, boost, buck-boost and SEPIC. And they need to incorporate protection features, such as protection for open LED strings, LED pin-to-VOUT shorts, and accurate undervoltage lockout thresholds. As with most solid-state circuitry, there is also a premium put on small compact footprints with minimal external components.

HB LED examples

The majority of automotive headlights still use incandescent technology. HID (high-intensity discharge) Xenon lamps were first introduced for use as automotive headlights in the late 1990s. However, they are expensive to produce and make, so they've been limited to high-end vehicles. Going forward, the recent introduction of HB LEDs will probably spell the decline of HID Xenon lamps for automotive use. Market analysts expect the HB LED headlight to have a large growth rate in the next decade.

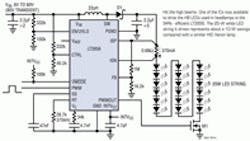

HID Xenon lamps typically dissipate about 35 W. An equivalent white LED headlamp that dissipates 25 W can be configured using an array of 18 LEDs in series with 350 mA of current. One way to drive such a configuration uses the recently introduced LT3956 monolithic LED driver from Linear Technology. The LT3956 is a dc/dc converter designed to operate as a constant-current and constant-voltage regulator.

The LT3956 features an internal low-side N-channel power MOSFET rated for 84 V at 3.3 A and is driven from an internal regulated 7.15-V supply. The fixed frequency, current-mode architecture results in stable operation over a wide range of supply and output voltages. A ground-based referenced voltage feedback (FB) pin serves as the input for several LED protection features and also makes it possible for the converter to operate as a constant-voltage source. A frequency-adjust pin lets the user program the frequency from 100 kHz to 1 MHz as a way to optimize efficiency, performance or external component size.

The LT3956 senses the output current at the high side of the LED string. High side sensing is the most flexible scheme for driving LEDs, allowing boost, buck mode or buck-boost mode configurations. The PWM input provides LED dimming ratios of up to 3,000:1 and the CTRL input provides additional analog dimming capability.

Some applications for high-power HB LED drivers need LED currents exceeding 10 A. These include DLP projectors, laser drivers, and architectural lighting. However, there can be a host of design problems delivering currents greater than 10 A, not least of which are thermal management issues within the end product itself! To this end, Linear Technology has developed a special LED driver.

The LT3743 is a synchronous step-down dc/dc converter designed to drive high-current LEDs with a constant current. It can deliver up to 20 A of continuous LED current or up to 40 A of pulsed LED current. The chip enables three-state current control for color mixing applications, as found in DLP projectors. It also offers fast (below 2 μsec) transition time from current levels that optimizes color mixing resolution and allows fast current pulsing in laser driver applications.

The LT3743's 5.5 to 36-V input voltage range lets it handle a wide variety of applications in addition to DLP projection, including industrial and architectural lighting. The chip provides up to 20 A of continuous LED current from a nominal 12-V input, delivering in excess of 80 W. In pulsed LED applications, it can deliver up to 40 A of LED current or 160 W peak from a 12-V input. Efficiencies as high as 95% eliminate the need for external heat sinking and significantly simplify the thermal design.

The LT3743 offers both PWM and CTRL_SELECT dimming to make possible dimming at three LED current levels. This helps handle such color mixing applications as those in DLP projectors. Similarly, the chip's topology lets it transition between two regulated LED current levels in less than 2 µsec, enabling more accurate color mixing in RGB applications. LED current accuracy of ±6% keeps the light output from several LEDs close to each other. Additional features include output voltage regulation, open-LED protection, over current protection and a thermal derating circuit.

Resources

Linear Technology Corp., Milpitas, Calif., www.linear.com