LED technology offers significant benefits in the established streetlight market. Up until a few years ago, this market relied upon mature sodium and metal halide lighting technologies. These lighting technologies are well understood and reliable, however, are now scrutinized from an economical as well as an environmental point of view. Many public services budgets are now under increased pressure, which has lead to a closer examination of not just the installation and maintenance costs of streetlights, but also the ongoing costs of operating them. Coupled with incentives for reduction in CO2 emissions, LED lighting has begun to demonstrate a lot of advantages that has prompted more widespread adoption.

The principle advantages of LED lighting are its long life, which can be as long as 100,000 hours or 20 years, and its inherent energy efficiency. They have been shown to use 15 percent of the energy and give off less heat than an incandescent bulb while generating more light per watt. LEDs do not contain toxic chemicals such as mercury, compared to high-pressure sodium lamps or mercury-vapor lamps. Because of their long lives, there are reduced maintenance costs and are an optimal solution for lighting in places where replacing light bulbs is expensive, inconvenient or otherwise difficult.

LED streetlights offer additional advantages that include enhanced night visibility from increased color rendering, color temperature and brightness uniformity. Plus, they can be turned on quickly because no warm up is needed, and they do not produce ultraviolet light, which is what attracts bugs. With an LED streetlight design, developers also have more flexibility in controlling light levels which opens up the opportunity to implement programmable controls, and direct light on specific areas from the directional light LEDs emit in one direction.

Related Articles

- Designing LED Lighting Systems For Optimal Light Output

- Dimming LED Lamps: It's All About the BOM vs. Lifetime and More

- LED Lighting Power & Dimming Controls

- Cree LEDs Light Up the Largest Municipal Street Lighting Project in China

Public services and utilities organizations calculate streetlight cost of ownership as the total of their installation, maintenance and ongoing electricity costs. LED technology has had previous false starts where light output, reliability or temperature effects have resulted in a disappointing outcome. With a reported 20% of global energy used for lighting, the energy cost and CO2 reduction advantages realized with LED technology has resulted in LED technology gaining more positive acceptance for streetlights.

Streetlight Reliability

A major hurdle to LED acceptance is reliability. This is where standards such as Energy Star come into consideration with strict requirements for light output and expected life expectancy. Compared to high-pressure sodium light that has an estimated life expectance of up to 30,000 hours of expected life, LED lighting supplies 60,000 hours of expected life -- double the lifespan. Because LED lighting technology today offers enhanced light output for a given input power (efficacy) and improved light delivery where it is needed with less light spill or pollution, an energy savings of up to 50 % has been calculated for LEDs compared to existing technologies.

Another reliability concern is that streetlight and industrial lighting luminaires often differ from domestic/consumer-based ‘plug and play’ lighting. Streetlight designs are typically configured with a control unit or power supply at the pole base, and the luminaire remote at the top. These streetlight luminaire sub-assemblies require careful commissioning on site as part of an overall fixture, which introduces potential problems. Electricians typically need to have direct contact with boards, subsystems and connectors during installation. Because of the variety of streetlight luminaire components involved, there are numerous areas where the luminaire can be potentially exposed to stress from the moment of installation.

The first potential problematic issue involves the possibility of miswiring while the LED module is being installed, and miswiring can be as simple as reversing polarity. The luminaire can also be exposed to electrostatic discharge (ESD) that can result from a craftsperson’s handling of the sub-assemblies and while an exposed LED module is being handled before being mounted into the lens fixture. LED luminaire stress can also be the result of sealed enclosures where temperature extremes of -40 °C to 125 °C are not uncommon and can be further exacerbated due to environmental and self-heating conditions.

LED Shunt Protectors

Most LED streetlight designs feature solid-state lighting luminaries configured in series strings of twenty or more LEDs. In this configuration, an open LED can cause the entire LED string to go dark, which leads to lower reliability, reduced performance, potential maintenance calls or costly warranty returns.

Adding an LED Shunt Protector (LSP) device to an LED design allows the unaffected lights in the string to remain illuminated by shunting current around the inoperable LED. To allow the remaining LEDs to continue working in the presence of a single open-circuit LED, an electronic shunt current bypass such as an LSP device provides a means to isolate the open circuit and allow current to flow uninterrupted through the string of LEDs. During normal operation of the LED circuit, the LSP device is inactive and no current flows through the device. Only in the event of an open circuit does an LSP become active.

LSP devices are selected with a breakover voltage proportional to the number of intended LEDs in a substring -- high enough not to clip the forward voltage and lower than the voltage that exists across an open circuit LED when the breakover current is drawn. Whenever the voltage across the device exceeds the rated breakover voltage, the LSP device switches to its “on” state. In this state, the voltage across the LSP device falls to about 1 V and minimizes power dissipation, which is actually less than the dissipation of the LED, possibly even preventing further failures. Furthermore, the LSP has a low standby current when it is the off state to ensure minimal system power loss. The required current to operate an LSP device must be less than the current consumed by an operational LED. To ensure the LSP switches on reliably, the breakover current is specified below the minimum LED operating current and high enough to prevent false triggering.

Compared to low-power LED string designs that typically use zener diodes instead of LSP devices, high-power LEDs needed for streetlight designs require very large and expensive zeners. In addition, certain LEDs come equipped with an integral zener diode. However, these diodes are designed to provide only ESD protection for the LED die and are incapable of continuously handling the full operating current of the LED. Of particular note, integrated zener diodes are usually connected via the same wire bond as the LED die so that when the wire bond fails, the ESD diode typically is disconnected as well.

Optimal LED Streetlight Design

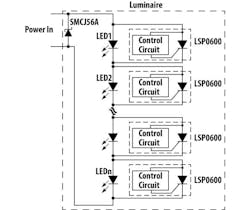

The circuit in Fig. 1 illustrates an optimal configuration for a streetlight luminaire. In this configuration, if the power is accidentally reversed during installation, the forward diode characteristic will protect the LED string from damage, while also protecting against fast transients at the power terminals.

An important fact that streetlight designers should also consider is that in highly stressed LED strings, LEDs can develop an open circuit state. This is often a result of cooling and heating that applies stresses inside an LED package. An added advantage of utilizing an LSP device in this design example is that it helps to maintain illumination in the remaining LEDs in the string if an LED goes into an open circuit state as a result of electrical or thermal damage.

Implementing Effective Current Control

Unlike a sodium lamp that typically requires a simple 50/60 Hz magnetic ballast and starter, a multi-LED streetlight uses a modern switching inverter to drive it, which introduces additional design challenges. To maximize operational life, LEDs must have effective current control and also maintain the expected light output. LED ballasts may also need to control light output for motion detection or dimming for periods when the space is unused. A popular design is to interconnect an entire street in zones to illuminate when pedestrian or vehicle activity is detected.

LED streetlight applications require the latest robust, small form factor and high-frequency switching inverters to perform power factor correction and precise current control that must operate reliably in the harsh environment of streetlight installations. Adding to the challenge are recent developments that interconnect streetlights, either by RF radio links or wired control lines for a system control approach. This new interconnection scheme with built-in intelligence results in more sensitive high-value circuits, which need to be protected from lightning and AC events and faults.

A solution for effective circuit protection in high-current LED streetlight applications are PowerTVS (PTVS) diodes that can deliver bidirectional protection up to 470 volts, and also meet IEC 61000-4-5 8/20 μs surge requirements. Today’s advanced technology in the PTVS products offers lower clamping voltage under surge compared to competing varistor technology.

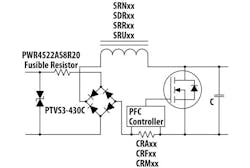

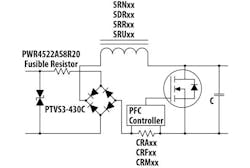

Fig. 2 shows how a typical streetlight LED power supply may be configured using a high Power TVS diode (PTVS) instead of a more common varistor to protect against transients in this electrically-exposed environment. Completing the power supply design, Bourns has a broad selection of inductors available in high current, flat wire, semi-shielded and fully shielded options to maximize performance.

In addition, tight current sensing control can be achieved with current shunts. These current sense resistor devices satisfy requirements for very high accuracy, broad operational temperature tolerance and high power density. These highly specialized resistors are capable of withstanding surges without a material change in the characteristics of the resistor. Furthermore, current shunts provide total resistance values less than those required by industry standards, which gives engineers enhanced design flexibility.

Reliability Challenges

As illustrated here, there is a variety of circuit protection devices that offer solutions to many of the reliability challenges faced by developers of streetlight or industrial LED lighting applications. Of key value is that open LED failure can be addressed with today’s advanced LSP devices.

PTVS diodes are an important solution for enhanced reliability as well. These diodes deliver effective protection for applications in an electrically exposed environment of streetlights where varistors may not be able to offer the required performance as they can degrade during service life, and cost of replacement or repair in remote locations can be prohibitively high. Offering a wide voltage range, low clamping voltage under surge, standards compliance and consistent performance, PTVS diodes match a broad range of application requirements.

Overcoming the reliability concerns that have plagued more widespread LED technology adoption, OEMs can now supply LED streetlight solutions that deliver significant advantages. Ensuring reliability allows municipalities and public services agencies to realize the full longevity, energy savings, minimal maintenance and additional functionality benefits LED technology has promised.