A Guide to Designing Gate-Drive Transformers

As electrical circuits become more complex, the demand for expert electrical engineering becomes more critical. Precise engineering is essential at every stage of designing a circuit, and it is equally important in the design of the components. One component that must be carefully designed is the gate-drive transformer in a switch-mode power supply (SMPS).

A gate-drive transformer is needed in a SMPS to control the timing of the circuit. These devices provide electrical pulses for turning on and off semiconductors, such as high-voltage power MOSFETS or IGBTs. They also are used for voltage isolation and impedance matching. Gate-drive transformers are essentially pulse transformers that are used to drive the gate of an electronic switching device. Assuming optimal values for rise time, droop and overshoot, the application is what discriminates the gate-drive transformer from other transformers.

The basic gate-drive transformer has several design variations, each of which is determined by the specific application. Some common schematics and their corresponding turns ratios are listed in Fig. 1.

Typical gate-drive transformers are designed using ferrite cores to reduce cost. Some of the common core packages are EE, EER, ETD and EFD. These types of cores are “E” shaped and have a corresponding bobbin. The bobbins can be surface mount or thru hole. In some cases, a design will use a toroid.

A typical pulse-transformer design requires the parameters shown in Table 1.

If there is a requirement for a safety standard (UL, VDE, CUL, IEC or TUV), then the design must involve certain creepage and clearances. Documentation will need to be purchased from the safety agencies for the required creepage and clearance requirements.

If the application is for military purposes, then the choice of manufacturing materials may need to be noncompliant with the Restriction of Hazardous Substances (RoHS) directive. Magnetics design engineers need to understand this directive because it limits the selection of materials that can be used in the transformer, potentially impacting performance.

The first step is to determine the core material. This is based on the operating frequency. Table 2 lists several core vendors and the recommended ferrite materials for three different frequency ranges.[1] The operating frequency of the SMPS will determine the amount of inductance that is needed on the primary of the gate-drive transformer. A general guideline is listed in Table 3.[2]

Two of the critical electrical parameters to control when designing a gate-drive transformer are the leakage inductance and winding capacitance.[1] A high leakage inductance and winding capacitance may cause an undesirable output signal such as phase shift, timing error, noise and overshoot. Leakage inductance happens when a winding has poor coupling. High winding capacitance results when a winding has many turns and the turns are not laying uniformly during the winding process.

Leakage inductance can be kept to a minimum at the electrical design stage and also in defining the manufacturing specification. There are many formulas to calculate an approximation of what leakage inductance to expect for a particular design.

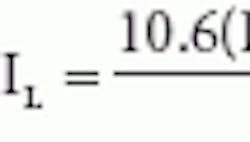

One of the formulas[3] used to estimate leakage inductance in the magnetics design is the following:

where IL equals the leakage inductance of both windings in Henrys, N equals the number of turns in the winding, MT equals the mean length turn for the entire core in inches, n equals the number of dielectrics (insulation) between windings, c equals the thickness of dielectrics (insulation) in inches, a equals the winding height in inches and b equals the winding traverse in inches.

One thing to avoid at all costs is to have a winding with a half-turn. The half-turn is an uncoupled turn and the leakage inductance will be high. The winding capacitance should be kept within the picofarad range (less than 100 pF is desirable).

In manufacturing a gate-drive transformer, the leakage inductance can be limited by using the proper winding method during manufacture. Fig. 2 shows a winding specification that displays the method of winding from the center. The winding specification produces the configuration reflected in Fig. 1c. Note that the line between the endpoints Start 1 and Finish 6 are on the primary side.

This winding-from-center method will increase the inductive coupling of the turns. The step-by-step process of how to wind this part is as follows:

-

With two wires in hand, red and green (start points Start 2 and Start 3), bifilar wind 10 turns.

-

Now add the natural wire and wind trifilar, with three wires in hand (this stage is noted with the start point Start 1) for an additional 20 turns. Stop winding the natural wire after a total of 30 turns. This stage is reflected by the endpoint Finish 6.

-

Bifilar wind 10 more turns with the red and green wires together, bringing these wires to a total of 40 turns. This stage is marked by endpoints Finish 4 and Finish 5.

Now that the basic information has been presented for designing and winding a gate-drive transformer, the design can be completed using Fig. 1c as a reference design example. The inductance range will be kept between 50 µH and 500 µH, per Table 3. The electrical requirements for this transformer are shown in Table 4.

As previously mentioned, the first step in designing a gate-drive transformer is to decide what size core to use and what core material. The most compatible material for this particular application is 3F3, or equivalent, from Ferroxcube, as listed in Table 2.[4]

Because the power level is listed as less than 5 W, an E5.3/2.7/2-3F3 is chosen. The AL value (rated in milli-Henrys per thousand turns) of the core is listed as 265 « 25% (199 to 331). The core area is 0.0265 cm2.

The turns are calculated using the following formula:

where B equals the flux density in Gauss, ACORE equals the core area in square centimeters and ET equals the volt-microsecond constant in volt-microseconds.

ET measures the energy-handling ability of a transformer or inductor, and depends on core area, core material, number of turns and the duty cycle of the applied pulse.

A Gauss level of 2000 will be used in this design. At this Gauss level, there is no risk of saturating the core, because BSAT of the 3F3 material from Ferroxcube is 4000 Gauss. Also, because this is an E core, there is a small gap at the mating surfaces that aids in preventing the core from entering saturation.

Establishing Turns Numbers

With all the parameters known, using the following equation, the primary turns can be calculated:

where B equals 2000 Gauss, ACORE equals 0.0265 sq cm (core area) and ET equals 10.5 V µs. With the turns on the primary being 20, the secondary will be 40 turns to meet the 1-to-2-to-2 turns ratio.

Determining Wire Gauge

The current will be calculated using 50 μH for the minimum primary inductance, as per Table 3.

The input current is calculated using the following formula:

The wire size on the primary is calculated using this equation:

AWIRE=(circular mils per ampere)(IIN)(DT),

where AWIRE equals the wire area in circular mils, IIN equals the input current and DT equals the duty cycle.

Substituting 500 circular mils per ampere, 255 mA for current and a duty cycle of 50% yields an area of 63.75 circular mils, provided with margin by a wire size of #32. For the primary, #32H wire will be used (MW80C [155°C]). MW80C is chosen because it meets the 130°C upper temperature limit and because it is solder strippable, easy to solder strip in manufacturing.

The secondary wire size will be based on a current level of 3 mA in each winding. The calculated area in circular mils for each winding is 1.5. Therefore, #48H wire will be used on each secondary.

Completing the Design

Once the wire sizes have been calculated, the next task is to ensure all the materials fit into the package. An appropriate adhesive must be chosen to glue the ferrite cores together. The primary open circuit inductance is verified with the following formula:

With the tolerance in the AL value of the core («25%), the minimum inductance would be 79 µH. This inductance is relatively small, but it meets the design requirements. The minimum inductance that had to be met was 50 µH. The turns could be increased to raise the inductance, but the capacitance will be compromised. Therefore, the 20 turns specified will remain.

Finally, a complete outline package is ready to be presented to the customer (Fig. 3). A final bill of materials for the completed design is shown in Table 5.

References

-

Wagner, J. “Solid State Tesla Coils — General Notes,” http://users.tkk.fi/~jwagner/tesla/

SSTC/general-sstc-notes-gatedrv.htm,

pp. 2-3. -

Andreycak, Bill, Unitrode Switching Regulated Power Supply Design Seminar Manual, “1MHz 150W Resonant Converter Design Review,” Unitrode Corp., 1988.

-

Lee, Rueben, Electronic Transformers and Circuits, 2nd Edition, John Wiley & Sons Inc., 1947, p. 76.

-

Ferroxcube Soft Ferrites and Accessories Data Book, 2004.