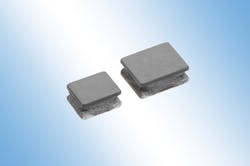

Compact Metal Power Inductors For Mobile Devices

TDK Corporation presents the new VLS-HBX series of compact metal power inductors, which feature a very low profile of just 1.0 mm, combined with a high current capability. The two new types have footprints of 2.0 mm x 1.6 mm and 2.5 mm x 2.0 mm, respectively. Thanks to the use of a magnetic metal core material with a high saturation flux density, the power inductors offer rated currents of up to 6.0 A DC, depending on type. Their current capability is thus up to 80 percent higher than that of existing products whose cores are based on ferrite materials. In addition, TDK was able to achieve DC resistance values that are 40 percent lower than those of current products through the use of advanced core forming technology and optimized structural design. The VLS-HBX series is designed for use in the power supply circuitry of smartphones, tablet PCs, and other mobile devices. Mass production began in November 2013.

The mobile phone market is characterized by the rapid evolution of smartphones to offer ever higher performance and a greater array of functions. The power supply circuitry of such devices requires multiple inductors that are rated for high currents, yet offer a small footprint and low profile. The use of the newly developed TDK inductors will help to increase power supply efficiency and extend battery life.

The new VLS-HBX series joins the existing VLS-E series, resulting in a highly versatile lineup of power inductors for power supply applications in mobile devices.

Main applications:

- Smartphones, tablet PCs, digital cameras, etc.

- Power supply modules Main features and benefits

- Current capability increased by 80 percent through the use of a magnetic metal core material with a high saturation flux density

- DC resistance decreased by 40 percent through the use of advanced core forming technology and optimized structural design