Precision Resistor Dividers Extend HV Battery Life

Texas Instruments' RES60A-Q1 integrated, 1.4-kV, single-chip thin-film resistor divider helps extend the lifetime of hybrid, electric-vehicle, and battery energy storage system (BESS) batteries when incorporated into battery-management systems (BMS). Today’s BMS designs typically use long chains of discrete resistors whose drifting tolerance degrades voltage-sensing accuracy over time, causing state-of-charge and battery state-of-health estimation errors.

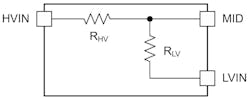

The RES60A-Q1 is a matched resistive divider (Fig. 1) implemented in thin-film SiCr with the company's modern, high-performance, analog wafer process. A high quality SiO2 insulative layer encapsulates the resistors and enables usage at extremely high voltages, up to 1,400 V DC for sustained operation or 4,000 V DC for HiPOT testing (60s). The device has a nominal input resistance of RHV = 12.5 MΩ, and is available in several nominal ratios to meet a wide array of system needs.

The RES60A-Q1 eliminates the need for lengthy discrete resistor chains with a single-chip, high-voltage resistor divider. It achieves 0.1% initial ratiometric precision with a maximum of 0.2% ratiometric drift over a 10-year lifetime, providing accurate and consistent monitoring of the battery pack.

Such precision is maintained over the specified temperature range and aging, with a cumulative drift of only ±0.2% (max). Therefore, the lifetime tolerance of an uncalibrated RES60A-Q1 remains within a ±0.3% (max) envelope. Ratios of 1,000:1, 145:1, 210:1, 310:1, 315:1, 410:1, 500:1, 510:1, and 610:1 are available.

The RES60A-Q1 is automotive qualified under AEC-Q200 temperature grade 1, with a specified temperature range from –40 to +125°C. It features a nominal input resistance of 12.5 MΩ, and withstands temperature and 4-kV DC HiPOT (60s) tests to maintain accuracy, helping engineers meet strict high-voltage design requirements.

Features

- AEC-Q200 qualified for automotive applications

- Temperature grade 1: –40°C to +125°C

- High voltage rating: Survives 3+ HiPOT tests at 4,000 V DC (60s), 1,700-V DC creepage and clearance support between HVIN and LVIN (IEC-61010 PD 2)

- High dc precision with low shift and drift

- Initial ratio matching precision: ±0.1% (max)

- Low drift: ±1 ppm/°C (typ)

- Accurate ±0.2% across aging and temperature

- Low thermal noise (1 kHz) thin-film resistors: 30 nV/√Hz (210:1 ratio), 2 5nV/√Hz (310:1 ratio), 22 nV/√Hz (410:1 ratio), 20 nV/√Hz (500:1 ratio), 18 nV/√Hz (610:1 ratio), 14 nV/√Hz (1,000:1 ratio)

Applications

- High-voltage bus and battery voltage monitoring

- HEV/EV battery management system (BMS)

- HEV/EV DC-DC converter

- HEV/EV onboard charger (OBC)

- HEV/EV inverter and motor control

Packaging and Design Considerations

The device is offered in an 8-pin SOIC package, with nominal body size (7.5 × 5.85 mm), and features creepage and clearance distances of at least 8.5 mm between the high- and low-voltage pins.

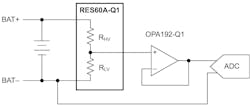

The RES60 evaluation module (EVM) is designed to help users easily evaluate and test the operation and functionality of the RES60 device in the typical configuration, (Fig. 2). The EVM is configured as a resistor divider followed by an operational-amplifier buffer. The EVM operates on a split-supply from ±0.9 to ±2.75 V. The default configuration of the EVM uses a resistor divider of 500:1.

For more details on the application of high-voltage resistor dividers, check out Texas Instruments' contributed article on them in our Automotive Electrification (BMS) eBook, downloadable here.

At the time of this writing, the RES11A40DDFR is in distributor stock and priced at around $1.08 for 1k pieces. The RES60A-Q1 Evaluation Board is available for about $99.

For Electronic Design readers' convenience, the RES60A-Q1 datasheet is provided below, though it would be wise to obtain the latest revision and other RES60-A1 design resources from TI before starting a design.

To keep up with Electronic Design’s latest automotive-related articles, please subscribe to our Automotive Electronics bi-weekly newsletter.

About the Author

Andy Turudic

Technology Editor, Electronic Design

Andy Turudic is a Technology Editor for Electronic Design Magazine, primarily covering Analog and Mixed-Signal circuits and devices and also is Editor of ED's bi-weekly Automotive Electronics newsletter.

He holds a Bachelor's in EE from the University of Windsor (Ontario Canada) and has been involved in electronics, semiconductors, and gearhead stuff, for a bit over a half century. Andy also enjoys teaching his engineerlings at Portland Community College as a part-time professor in their EET program.

"AndyT" brings his multidisciplinary engineering experience from companies that include National Semiconductor (now Texas Instruments), Altera (Intel), Agere, Zarlink, TriQuint,(now Qorvo), SW Bell (managing a research team at Bellcore, Bell Labs and Rockwell Science Center), Bell-Northern Research, and Northern Telecom.

After hours, when he's not working on the latest invention to add to his portfolio of 16 issued US patents, or on his DARPA Challenge drone entry, he's lending advice and experience to the electric vehicle conversion community from his mountain lair in the Pacific Northwet[sic].

AndyT's engineering blog, "Nonlinearities," publishes the 1st and 3rd Tuesday of each month. Andy's OpEd may appear at other times, with fair warning given by the Vu meter pic.