What you’ll learn:

- Enhancements of the new Intel Atom processor series versus Apollo Lake.

- The benefits and features of the Intel Elkhart Lake processors.

What industrial IoT applications need today is a combination of high-performance, low-power processor technology, robust real-time operation, real-time connectivity, and real-time hypervisor technologies. To address those needs, the latest Intel Atom, Celeron, and Pentium processor generation offers more power for low-power applications.

The low-power Intel Atom, Celeron, and Pentium processors (aka Elkhart Lake) targets the embedded and edge-computing market, specifically when it comes to fanless low-power embedded computing from 4.5 to 12 W.

Processor Performance Boost

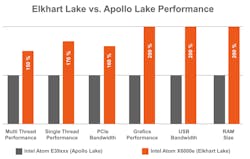

The latest Atom, Celeron, and Pentium processors offer a performance boost of up to 50% multi-thread and even up to 70 % single-thread performance over their predecessors based on the Apollo Lake microarchitecture (Fig. 1).1 For many industrial applications, it’s also important that the extended temperature range from −40 to +85°C is supported.

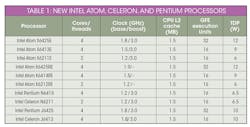

With up to four cores and maximum clock rates of up to 3 GHz in boost mode, the new processors bring significant performance improvements to the embedded market, including single as well as multi-threaded applications (Table 1).

However, the fact that Intel Atom processor technology is now available in 10 nm is of even greater importance for embedded applications. Embedded users of the previous low-power Intel architectures with the code names Apollo Lake (14 nm), Braswell (14 nm) or Bay Trail (22 nm) who are migrating to the new Elkhart Lake variants, can therefore benefit from Intel’s SuperFin technology for the first time. The chips are amenable to a range of small form factors (Fig. 2).

Next to higher packing density, this offers either lower power consumption at the same performance, or higher performance at equal TDP. Both aspects are key in embedded designs. A comparison of the new designs, which are available in variants from 4.5 to 12 W, shows that users of each TDP class can benefit from significant performance increases. And since the power-saving modes of the processors are Energy Star 3.0 certified, connected applications consume very little power in standby mode without the need for a special network proxy chip.

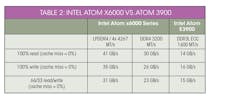

The increased data throughput is supported by more RAM—Elkhart Lake supports up to 32 GB of LPDDR4 memory with up to 4267 MT/s; the Apollo Lake series could only support 8 GB of LPDDR4 with up to 2400 MT/s. Mission-critical real-time applications also benefit from more cost-effective error-correction-code (ECC) implementations, as Intel Inband Error Correction Code (IBECC) allows the use of more affordable conventional memory instead of dedicated ECC RAM. Customers can configure the ECC and non-ECC mode in the BIOS.

The fact that it’s possible to apply IBECC only to certain memory areas is a particular advantage, because developers don’t have to choose between all or nothing. For example, the memory area reserved for a mission-critical virtual machine can be protected from data errors by applying IBECC, while the remaining main memory operates without this feature in favor of higher data rates. But even with activated IBECC, the achievable data rates are often more than twice as high as with DDR3L ECC memory on Intel Atom E3900 processors (Table 2).

Doubling Graphics Speed for Immersive Experiences

The new processor series also offers impressive graphics with twice the speed for up to 3X 4k @ 60 fps and 10-bit color depth.2 This increase in graphics performance was made possible by integrating the Intel Gen11 graphics unit, which had already been built into the significantly more powerful Intel Core processors of the 10th generation (Ice Lake). Again, the GPU sits on the CPU die and benefits from the performance and energy optimizations of the 10-nm manufacturing technology.

Above all, though, the performance increase stems from the number of integrated execution units (EUs)—there are up to 32. The graphics performance therefore doubles simply due to the higher efficiency and increased number of EUs, since the low-power Gen9 graphics of Apollo Lake had a maximum of 18 EUs.

The Gen11 graphics addresses the resulting higher bandwidth requirements with better compression, larger L3 cache, and higher maximum data transfer rates. It also supports all major acceleration APIs, including DirectX 12, OpenGL 4.5, Vulkan 1.1, OpenCL 1.1, and Metal, suiting it for 3D graphics and a wide range of GPGPU-driven applications. Video-heavy applications, such as digital signage, gaming, streaming clients, and AV head-end systems, benefit from hardware-accelerated encoding and decoding of the latest codecs, such as the data-efficient but also compute-intensive HEVC (H.265) and VP9, as well as the widely used predecessors AVC (H.264) and AV1.

Higher Data Throughput Thanks to PCIe Gen3 and USB 3.1 Gen2

For many developers, higher data throughput to peripherals will also be a key benefit of the new Intel Core processors. For the first time, PCIe Gen3 is available in low-power processors, which means that the data rate has doubled to a maximum of 32 GB/s (16 GB per outward and return channel) compared to PCIe Gen2 as supported by Apollo Lake. This is now achieved at 8 GHz instead of 5-GHz clock frequency.

Another new feature for low-power x86 is USB 3.1 Gen2 support, which offers a sizable performance increase compared to USB 3.1 Gen1. At up to 10 Gb/s, this enables 2X faster data transfers compared to USB 3.1 Gen1, making it possible to transfer uncompressed UHD video signals—e.g., from a camera to a monitor—via USB for the first time.

However, increasing the clock rate of peripheral buses can significantly impact system design because it creates new challenges for carrier-board developers, especially in terms of signal compliance. Higher clock rates make routing much more complex and error-prone.

Consequently, OEMs should look for embedded vendors that offer comprehensive board design services and compliance tests. This saves customers from having to rely on external laboratories and, in the event of problems, they can speak directly to the experts who have already thoroughly tested numerous other COM and carrier combinations.

Hard Real Time—Even via Standard Ethernet

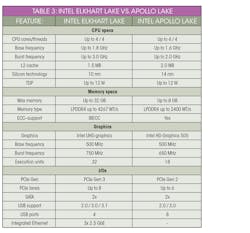

Another benefit is the time-synchronized networking (TSN) support with Intel TCC (Time Coordinated Computing), and RTS Hypervisor support. In contrast to Apollo Lake, the new Intel Atom processors now implement native Ethernet support for the highest bandwidth with 3x 2.5-GbE LAN (Table 3).

Where TSN enables tactile internet applications over IP in hard real time, the TCC technology orchestrates real-time Intel IP-based communication also toward the I/Os to reduce latency and minimize jitter in synchronous processes. It can be adjusted via the Intel TCC Software Toolkit. This can be useful for real-time applications in the transportation sector, where the processor-integrated CAN bus must be integrated.

Comprehensive Virtualization Support for Hardware Consolidation

Naturally, hardware virtualization plays an important role in connected real-time systems since real-time multitasking is a key requirement for IoT and edge devices. The Intel Atom processors support virtualization with Intel VT technology, which is an attractive addition to real-time hypervisor technologies with the RTS Hypervisor.

VT technology supports single-root I/O virtualization (SR-IOV), for example. This allows multiple apps hosted in virtual machines with general-purpose operating systems (GPOS) to natively access an I/O interface, e.g. one of the Ethernet interfaces. This is a rather attractive feature, especially because these interfaces are often in short supply.

Real-time hypervisors like Real-Time Systems’ RTS Hypervisor combine seamlessly with the hardware-integrated virtualization capabilities of Elkhart Lake processors to run critical real-time applications—in parallel to other multi-purpose operating systems such as Linux and Windows—without causing any additional latency. So, virtualization primarily helps to consolidate numerous tasks on a single system.

In addition, the number of tasks continues to rapidly multiply in next-generation industrial control systems, which these days, on top of site control, are often required to interact with each other in real time. Furthermore, industrial-IoT-based data exchange is needed to monitor distributed machines, optimize asset performance, and introduce new business models with predictive maintenance and as-a-service offerings.

Artificial Intelligence and Machine Vision

Artificial intelligence is widely used for edge analytics today. The new Intel processors support an extensive portfolio of AI products and optimizations for common frameworks. Particularly noteworthy are OpenVino and Microsoft ML support. Microsoft ML is a free machine-learning software library for the programming languages C # and F #. It also supports Python models when used in conjunction with NimbusML. The OpenVINO toolkit includes the Intel Deep Learning Deployment Toolkit, optimized OpenCV and media encoding and decoding routines, as well as 20 pre-trained models and code samples.

Workload Consolidation Kit for Machine Vision

The workload consolidation kit for vision-based situational-awareness applications from congatec (Fig. 3), which is Intel-qualified as a production-ready Intel IoT RFP Ready Kit, demonstrates the efficiency benefits of virtualization. It offers three virtual machines (VMs) for workload consolidation of vision applications based on RTS’s hypervisor technology.

One VM runs a vision-based AI application using Intel OpenVino software for situational awareness. The second VM is real-time capable and operates deterministic control software, while the third VM acts as an IIoT/Industry 4.0 gateway. The congatec kit, which was developed in cooperation with Intel and RTS and can be made available with the new Atom processor generation, targets the next generation of vision-based collaborative robotics, machine controls, and autonomous vehicles that need to perform multiple tasks in parallel, including situational awareness based on deep-learning-based AI algorithms.

Significant Security Improvements

All IIoT edge devices must integrate security features. OEMs can use virtualization technologies such as the RTS Hypervisor to integrate them. However, ideally, the foundation is already anchored directly in the hardware.

The new low-power processor generation has a lot to offer in this respect, too. For example, congatec’s new Intel Atom-, Celeron-, and Pentium-processor-based boards and modules offer options for more comprehensive out-of-band management. And there are embedded security features such as verified boot via Intel Boot Guard 2.1, TPM support including Intel Platform Trust Technology (Intel PTT), and Intel Dynamic Application Loader (Intel DAL) to help with the development of consistent, trusted applications.

In terms of data encryption and decryption, the new boards and modules feature Intel Advanced Encryption Standard New Instructions (AES-NI) and the SHA Extensions for hardware-accelerated secure hash algorithms, which are now even more powerful. A completely new feature involves processor support of SMx ciphers, a set of standard algorithms that are especially used in China. Lastly, HDCP 2.3 copy protection, which is necessary for the playback of the latest HD media, is now available.

References

1. Source: Intel. Claims based on a) SPEC CPU 2006 metric estimates based on Pre-Si projections and b) 3DMark11 estimates based on Pre-Si projections, using Intel Pentium J4205 as prior gen.

Configurations:

- Performance results are based on projections as of September 1st, 2020

- Processor: Intel Pentium J6425 PL1=10W TDP, 4C4T Turbo up to 3.0 GHz

- Graphics: Intel Graphics Gen 11 gfx

- Memory: 16-GB LPDDR4-3200

- OS: Windows* 10 Pro

- Compiler version: IC18

- Processor: Intel Pentium J4205 PL1=10W TDP, 4C4T Turbo up to 2.6 GHz

- Graphics: Intel Graphics Gen 9 gfx

- Memory: 16-GB LPDDR4-2400

- OS: Windows* 10 Pro

- Compiler version: IC18

Performance numbers are Pre-Si projections and are subject to change. Results reported may need to be revised as additional testing is conducted. The results depend on the specific platform configurations and workloads utilized in the testing, and may not be applicable to any particular user’s components, computer system, or workloads. The results are not necessarily representative of other benchmarks.

2. Source: Intel. Claims based on a) SPEC CPU 2006 metric estimates based on Pre-Si projections and b) 3DMark11 estimates based on Pre-Si projections, using Intel Pentium J4205 as prior gen.

Configurations:

- Performance results are based on projections as of September 1st, 2020

- Processor: Intel Pentium J6425 PL1=10W TDP, 4C4T Turbo up to 3.0 GHz

- Graphics: Intel Graphics Gen 11 gfx

- Memory: 16-GB LPDDR4-3200

- OS: Windows* 10 Pro

- Compiler version: IC18

- Processor: Intel® Pentium® J4205 PL1=10W TDP, 4C4T Turbo up to 2.6 GHz

- Graphics: Intel Graphics Gen 9 gfx

- Memory: 16-GB LPDDR4-2400

- OS: Windows* 10 Pro

- Compiler version: IC18

Performance numbers are Pre-Si projections and are subject to change. Results reported may need to be revised as additional testing is conducted. The results depend on the specific platform configurations and workloads utilized in the testing, and may not be applicable to any particular user’s components, computer system, or workloads. The results are not necessarily representative of other benchmarks.

About the Author

Dan Demers

Director of Sales & Marketing – Americas, congatec

Dan Demers holds a B.B.S degree in International Business from Grand Valley State University, Grand Rapids, Michigan and an M.B.A. from Ashford University, Clinton, Iowa. Mr. Demers has over 22 years of experience in embedded computing, having worked with Fortune 500 companies in the industrial, medical, and communications markets.