Advanced MCU Designs Empower Embedded Systems Development

This article appeared in Evaluation Engineering and has been published here with permission.

What you’ll learn:

- Information about the SiBRAIN standard

- "Plug & play" embedded systems development

- Thoughts on electronic design from the MikroE perspective

Being an embedded electronic systems designer was never an easy job, and in today’s disruptive evolutionary tech ecosystem, it’s getting even harder. Being an advanced product and/or service developer in the current environment is both enabled and challenged by the plethora of new technologies and solutions available. The ability to evaluate multiple solutions from a variety of vendors is becoming more and more valuable in the creation of a design.

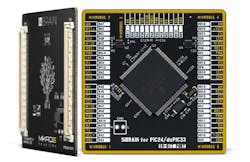

Addressing this aspect of embedded development from a microcontroller (MCU) selection perspective, MikroElektronika (MikroE), recently released SiBRAIN, presented as a standard for a modular plug-and-play development board system to enable easy swapping of various MCUs on a SiBRAIN-socket-enabled development board (Fig. 1). This enables embedded designers to try out multiple devices in their development phase without a massive hardware investment. SiBRAIN cards currently exist that support MCUs from major manufacturers including Microchip, NXP, STMicroelectronics, and Texas Instruments, with others to follow.

Each SiBRAIN board is self-contained, addressing the specific requirements of different MCUs, regardless of pin count or pin compatibility. Each card has male and female, high-speed, 168-pin mezzanine connectors with the SiBRAIN socket pin-out, and the design prevents incorrect orientation and placement. We spoke to Nebojsa Matic, CEO of MikroE, about the SiBRAIN system and what it can mean to the embedded systems designer.

EE: Glad to have you with us, Nebojsa.

Neb Matic: Glad to be here. By the way, everybody calls me Neb, it’s much easier. So, I’m an engineer who has been forced to run the company for 20 years. In setting the standard in MikroE, we were really encouraged by the mikroBUS standard. Based on that logic, we go further and standardize the socket and add-on board for all the microcontrollers in the world.

For example, a given legacy MCU card has a connector, it could be a pretty big one, it may be clumsy or delicate. You may not be able to put the MCU card back on the board when you remove it. So, we came up with this standard, we call it SiBRAIN. Why SiBRAIN? Because Silicon Brain, SiBRAIN, can do more than hold a microcontroller; you could also have Linux, or other OS, on such a board.

I’m looking forward to seeing an SiBRAIN card with Microsoft Azure Sphere, we already made an agreement with them to place media tech chips on that card. We already have an agreement and permission to do that with BeagleBoard. We don’t have an agreement and permission yet from Raspberry Pi, but we are looking forward to having it.

For the last 20 years we have been doing only dev tools and compilers. So, let me tell you something about MikroE. We are a 20-year-old company, with 80-plus employees, and we do only five things: development tools, compilers, peripheral boards, programmers, debuggers, and smart displays. Basically, we make a complete ecosystem for the development of any electronic device.

What is important for us is for you to know we are a highly organized group of people, with 2,000 of our own products. Most importantly, we release one new product per day. So, every day, at 10 o’clock in the morning, we introduce a new product, which never existed. It’s not 10 o’clock yet. So, I don’t know…

We set up an organization, with distribution, bookkeeping, an IT sector for our ERP system, production, marketing, and of course, sales, etc. We are like a small corporation, but we are so efficient, thanks to our ERP system, that we don’t need to have 500 people for what we are doing. The new card, by the way, it’s an SiBRAIN microcontroller card for PIC24, with a whole string of numbers afterward (Fig. 2). It’s a 100-pin card with 256K of flash memory.

We release one new product per day. How many products do you think we should have in the pipeline to be able to release one new per day? Every day in this company there are 250 projects in one of 12 stages. The first stage is an idea, the last stage is the web page, which means it’s finished.

EE: What are your thoughts on helping the design engineering efforts of your clients?

Matic: We are focused on one word—time. When we think about ourselves, we think that we sell time—and the products we produce are just a vehicle for how we are selling the time. We like to really free up as much of the time of our fellow engineers as we possibly could. With the tools we produce, you will do the most with the time you have. So, that’s how we see ourselves. For example, I like to go fishing, so when you say time, I almost calculate immediately in fishing time.

We provide fully featured development boards, small development boards, programmer debuggers, smart display, compilers, and peripheral boards. We have the biggest number of compilers available. The reason we have so many is because we make compilers from scratch. We have 1,000 peripheral boards with unique functionality. So, if you took a board with five sockets, and you have five sockets and 1,000 click boards, it gives you trillions of unique combinations. So just imagine how we make engineering easier.

EE: The nice thing about engineers is that you don’t sell them something by saying, “Now in purple," you know, if you have a direct benefit for an engineer, you’re going to get people who are going to use the solution. If you build it, they will come. Of course, you have to let them know it’s there, but if you have a good solution and you could present how it’s a good solution, then you’ll get at least the smart clients.

Matic: We want to make it so engineers could easily switch microcontrollers in their project. It keeps you from having to rely on only one microcontroller line, when there is another one which maybe fits better in your project. Or, just imagine if you are a design service company, and the guy who made the project left the company, and of course, he knew the best microcontroller to use. In this case, what you do is to just switch to another card, another microcontroller.

Another example could be, if you want to show your boss something on how your idea is working, you can use the biggest microcontroller with the most resources just to show him. Then when he says, “Yes, let’s go to make that project,” you can downsize to the right microcontroller, at the right price and everything. So there are a lot of reasons to switch the MCU easily. It’s all about scalability. You can either downsize for cost optimization, or if marketing comes along with a great idea, but it adds a bunch more memory, then you can go for the next MCU up in the series.

A SiBRAIN card is very small, it’s basically 60 x 60 mm, and we have it for so many different microcontrollers already, more than 100 right now. The most important part of the socket is those two 168-pin high-speed connectors, which means we could place 300 or so pins for any microcontroller, which right now don’t exist in the world. All you need is to place your microcontroller on the middle of that card, and connect to the appropriate pins, and that’s how you get compatibility.

It’s an open standard, so you don’t need to pay anything to us. If you want to place a socket on your board, if you want to make a SiBRAIN card, it’s up to you. We want to have a more universal tool because we like to cut down on MCU switching time, because that switching time is actually what engineers hate.

About the Author

Alix Paultre's Archive

Editor-at-Large

Also check out Alix's main author page for his latest articles.

An Army veteran, Alix Paultre was a signals intelligence soldier on the East/West German border in the early ‘80s, and eventually wound up helping launch and run a publication on consumer electronics for the US military stationed in Europe. Alix first began in this industry in 1998 at Electronic Products magazine, and since then has worked for a variety of publications in the embedded electronic engineering space. Alix currently lives in Wiesbaden, Germany.

Also check out hjis YouTube watch-collecting channel, Talking Timepieces.