I covered GreenWave Technologies' GAP 8 when it first came out. The GAP8 contained eight RISC-V cores, which seemed like a nice number. However, one was used to manage the system, leaving seven to handle the heavy lifting. That works most of the time, but the power of two has an affect when trying to distribute some chores. Thus, having eight cores plus one makes more sense, hence GAP9.

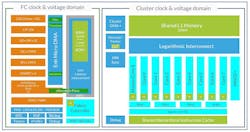

GAP9 is the latest incarnation with nine 32-bit RISC-V cores (see figure). The GAP9 is built using GLOBALFOUNDRIES’s 22-nm FDX process. The overall architecture hasn’t changed much, and these cores can handle machine-learning chores using platforms like TensorFlow Lite for Microcontrollers. Though the cores are optimized for machine-learning (ML) chores, there’s additional hardware that brings in floating-point and vector-processing support. This provides a significant performance boost for ML applications compared to GAP8.

The new processing support can work with 8-, 16- and 32-bit floating point as well 2- and 4-bit integers. It already handled 8-, 16- and 32-bit integers. The smaller numeric values provide more efficient ML model support. All of the processing elements share a memory subsystem that can deliver 41.6 GB/s. And the compute elements are able to deliver 50 GOPS of performance while using only 50 mW of power.

The GAP9 performs basic video processing with a CSI2 and parallel interfaces tied to an ML model like MobleNetV1. This can process 160- by 160-pixel video streams using only 806 μW/frame/s.

Other chip features include cryptography hardware that supports AES128/256. In addition, there’s a Physically Unclonable Function (PUF) unit.

About the Author

William G. Wong

Senior Content Director - Electronic Design and Microwaves & RF

I am Editor of Electronic Design focusing on embedded, software, and systems. As Senior Content Director, I also manage Microwaves & RF and I work with a great team of editors to provide engineers, programmers, developers and technical managers with interesting and useful articles and videos on a regular basis. Check out our free newsletters to see the latest content.

You can send press releases for new products for possible coverage on the website. I am also interested in receiving contributed articles for publishing on our website. Use our template and send to me along with a signed release form.

Check out my blog, AltEmbedded on Electronic Design, as well as his latest articles on this site that are listed below.

You can visit my social media via these links:

- AltEmbedded on Electronic Design

- Bill Wong on Facebook

- @AltEmbedded on Twitter

- Bill Wong on LinkedIn

I earned a Bachelor of Electrical Engineering at the Georgia Institute of Technology and a Masters in Computer Science from Rutgers University. I still do a bit of programming using everything from C and C++ to Rust and Ada/SPARK. I do a bit of PHP programming for Drupal websites. I have posted a few Drupal modules.

I still get a hand on software and electronic hardware. Some of this can be found on our Kit Close-Up video series. You can also see me on many of our TechXchange Talk videos. I am interested in a range of projects from robotics to artificial intelligence.