This file type includes high-resolution graphics and schematics when applicable.

With the recent application of nano-photonic interference filter technology, XYZ color sensing is moving out of the realm of laboratory instrument into more mainstream applications, including in-situ spectral sensing and lighting. In this article, we tackle 11 of the most common misconceptions about XYZ and its applications.

1. XYZ is just color like RGB, so who needs it?

Life (or at least light) is more than just red, green, and blue (RGB). In fact, when it comes to human vision, natural light sources deliver a broad spectral power distribution of visible light. Humans are fairly well adapted to the sun as our primary visible light source, and we’re also rather discriminating about color. However, the eye can be fooled when it comes to emitted light—so much so that a simple mix of blue and yellow was enough for us to see the early LEDs as white. But our eye isn’t so easily fooled when it comes to reflected light, especially in relation to color perception.

A particular color is perceived by an object reflecting some combination of wavelengths. In the simplest terms, the color has to be in the light in the first place. If some wavelengths are missing, the color isn’t represented accurately. For quick proof of this assertion, pull up a blank white screen on your monitor, and then use it as a light in a somewhat darkened space. Skin tone is a good thing to evaluate with this makeshift RGB light source; what you’ll see can be enough to send you to the doctor to figure out why you look so sickly.

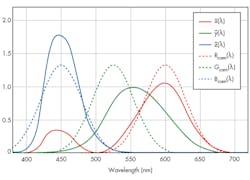

XYZ is the model for the standard response curve of the human eye, and is a result of how the long, medium, and short photoreceptor cone cells in the retina respond to spectral power distributions of light. You can see in the figure that while generally representative of the red, green, and blue areas of the visible spectrum, it does not match an actual RGB distribution.

It’s not difficult to imagine that if you draw some vertical lines representing a few reflected wavelengths that make up a color, you would get very different channel counts from an XYZ filter set, as compared to an RGB filter set. In fact, no amount of math can create an accurate value when data (wavelengths that weren’t sensed) aren’t present in the dataset.

2. XYZ sensors are expensive.

This myth was true in 2015, but not today. Interference filter technology, which builds up filters layer by layer in a CMOS-like process, has intersected high-volume integrated-sensor semiconductor manufacturing. The result is XYZ sensing that’s accurate and well-priced (generally $2 or less in high volumes). These benefits open up a host of new applications that did not make commercial sense just a few years ago.

3. XYZ sensors are only for high-end applications and won't make sense for applications such as lighting.

If it’s agreed that XYZ is better for general color sensing, then the issue becomes one of value. When cost isn’t much of an issue, the argument against XYZ for cost-sensitive applications such as standard commercial-grade lighting, and perhaps even replacement lamps and tubes, goes away. Granted, there is a cost, and throwing in an XYZ sensor just because it sounds cool doesn’t make sense.

If, for instance, light-to-light consistency over the full lifetime of a white/color tunable LED light is important, XYZ does makes sense. That’s because human color perception is typically discriminating enough to clearly spot a color difference between two adjacent color points that are just 0.2% apart. That means humans are very good at spotting the difference from light to light, so consistency requires sensing. For those who wish to lower their overall component costs, have access to a more cost-effective driver, or liberate a white- or color-tunable design from being captive to a single type of LED and supplier for ever and ever, then XYZ sensing can provide more than a little value.

The point of sensing in the first place is to find out what’s going on, and the reason to find out what’s going on in terms of color with a light is so it can be adjusted. What’s intriguing about the concept of closed-loop sensing is it will often enable a system designer to use lower-precision components, and gain a higher precision and/or more feature-filled result.

For example, the designer of a car’s power window could include highly precise window molding and manufacturing alignment, plus millimeter-accurate drive motors, or the designer could add a force-feedback sensor so that when the window hits the limits (either up or down), it stops the motor. In the latter case, lower-priced motors and looser tolerances on the glass could do an equally good job, and the designer has the benefit of an auto-stop if a finger or other object gets in the way. The result is a better product at lower cost.

That’s not to say that there isn’t a place for higher-end XYZ sensors. Companies get what they pay for in terms of sensitivity, dynamic range, or out-of-band rejection. Those can be important factors in some types of spectral sensing or in very low-light color sensing (admittedly it’s difficult to tell why one might care about color in low light, but no one knows what the next great app will be).

4. XYZ is complicated.

XYZ is complicated… at least when it comes to building a sensor to interpret it. Fortunately, the semiconductor R&D team only has to figure out that part once. Taking an XYZ value and mapping it to a color point or CCT is well-known “plug in the equation” math. That makes it simple for the rest of us to use XYZ sensing in our applications. And, conveniently, XYZ data is readily convertible to all kinds of other color maps, including RGB, sRGB, CIE-L*ab, L*ch, or L*uv.

5. XYZ sensors are large and power-hungry.

Those who define “large” as anything bigger than a square millimeter will find XYZ sensors to be large. But this myth is busted for those who are okay with a device that’s on the order of 2 × 2 mm. For power use, 150 µA in a high active state and 5 µA in sleep state makes XYZ just another low-power light sensor.

6. XYZ is of no use in a mobile device.

Often, designers need to see the technology is there to visualize its best application. Therefore, it’s likely that if a desirable app can make good use of true color-point detection in a mobile device, then, all else being equal, XYZ sensing will be of use. In this case, though, all else is not equal: XYZ gives a better result, and doesn’t necessarily have to cost more. Once a good app or two appear, XYZ will be in heavy demand to serve applications we had not originally imagined, but that will be highly useful.

7. XYZ calibration changes over time.

The XYZ sensor consists of several pieces—the filter, the diodes, and in an integrated device, analog-to-digital converters and some logic to provide a standard interface, such as I2C. Like most CMOS technology, the diodes and logic are all very stable over their lifetimes. Diode responses can vary greatly over temperature. However, that’s very straightforward to compensate for the addition of a dark channel, which delivers up a baseline count versus temperature that serves as a reference relative to the rest of the diode set. Subtracting the dark count from the active count on any particular channel provides the temperature-compensated value.

Because the filter response curves aren’t standard Gaussian designs (for instance, the extra bump in the blue region for the mostly red X curve), organic blocking filters, which do change over time, aren’t really an option for building an XYZ-shaped filter curve. The new generation of XYZ filters are typically based on interference filter technology, which involves complex layers of materials such as silicon dioxide effectively built up as glass in a CMOS-type process. Those filters are as stable as high quality glass.

In our labs at ams, we’ve seen the filter shift over temperature of approximately 1 picometer per degree Celsius. For a typical –40 to 85°C device, that’s less than one tenth of a nanometer across the visible range of 390 to 700 nm. That stability over lifetime and temperature range means that for all intents and purposes, a calibration done on any interference-filter-based XYZ sensor is good for life.

Incidentally, RGB filters are now being built with interference-filter technology as well. That comes in handy for RGB applications where sensing how much R, G, and B are present is important. However, it’s not the best option for true color identification.

8. I can convert RGB to XYZ, so I don't need XYZ.

Given that the human sensitivity to differences in color is on the order of 2/10ths of one percent or less, RGB can provide a decent answer, but not a perfect one. It’s important to note that if an RGB sensor was calibrated in a specific light, it can give very accurate color-point results for that specific light.

The advantage of XYZ is that it gives true color-point identification for light in general. By adding some intelligence, it gains the advantage of being calibrated as part of the chip manufacturing and test. That can eliminate the need for light-by-light calibration as part of the luminaire manufacturer’s build/test process, which can result in substantial time and cost savings. And with interference filters, that’s a lifetime calibration.

9. No applications require XYZ.

There certainly haven’t been many deployed applications using XYZ beyond light meters and other tools to evaluate lights and lighting, perhaps in some photography and broadcast settings, too. So, it’s true that not many applications benefit from XYZ sensing. However, that’s not to say many applications could benefit from XYZ sensing.

Tunable lighting is an obvious area that may very well benefit from true color metrics, as can some display technologies. With affordable XYZ sensing, we can also expect to see the emergence of myriad new spectral sensing applications.

One new application that has recently surfaced is portable true color evaluation for paint matching. Typically, consumers would have to take a swatch of material or a chunk of painted wall to the paint store, so that it can be analyzed for a matching color. Now they can use a compact, affordable instrument that will evaluate a color in-situ and then, with the help of a smartphone app, identify the exact paint code needed for a perfect match from a variety of paint manufacturers.

We can also expect to see a rapidly growing set of applications as XYZ sensors begin to appear in mobile devices, or as add-on accessories. “Enable it, and the apps will come” is becoming a standard mantra for many of our mobile devices.

10. There are no XYZ sensors on the market.

The expertise, technology, and equipment to build XYZ sensors is complex, so only a handful are on the market. However, they’re in production and available in several performance ranges from at least one large sensor manufacturer.

11. XYZ sensing always gives a better color answer.

Unfortunately, XYZ sensing doesn’t always provide a better color answer. It does give a better answer for the reflected true color of an object. However, when it comes to light sources, XYZ, similar to the human eye, can be fooled.

Fluorescent lamps are a case in point. If one makes a quick comparison of the spectral power distribution from a typical compact fluorescent light (CFL) to that of a warm LED, it’s clear that the CFL has several distinct spikes. It’s not by coincidence that those spikes match with the original color-rendering index test swatches.

While the easy path to efficiency is to produce only the wavelengths of light needed to obtain a good grade on the test, that’s not the best path to good color rendering of objects. If one evaluates the color of a CFL with an XYZ sensor calibrated for a more broadband light source, it can’t distinguish exactly where under the curve the energy is coming from, which can limit the accuracy. In that case, a sensor with more individual, narrower-band color channels could provide a better answer in identifying the color of the emitter. Those sensors also are currently available.

About the Author

Tom Griffiths

Senior Marketing Manager, Emerging Sensor Strategies

Tom Griffiths is Senior Marketing Manager for Sensor Driven Lighting at ams AG. He has spent the last 15 years as a strategic consultant, communicator, and evangelist immersed in LEDs, LED lighting, and the associated markets, including his roles as the founder and publisher of industry publications LIGHTimes, Solid State Lighting Design, and CompoundSemi Online. Tom's background prior to those endeavors included 15 years of staff-level marketing and sales management within the board-level embedded computer industry. He holds a BA and MA in economics from the University of California.