VITA’s Embedded Tech Trends 2017 conference was host to a range of new optical announcements.

Optical connectivity has significant advantages in electrically noisy, rugged environments. It does not have the crosstalk and distances issues that copper does. Optical connections are able to run faster and over longer distances, making them more desirable in rugged, embedded applications. Copper will still be used when possible because of its lower cost, but costs for optical interfaces and cabling continue to drop even as speeds increase.

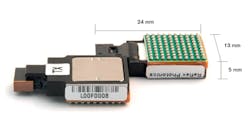

Reflex Photonics’ compact LightABLE series (Fig. 1) delivers up to a dozen 10-Gbit/s transmit and receive optical channels that are used in a range of rugged boards. Future plans will double the number of connections.

The top-end connectors provide 120 Gbits/s of bandwidth. They are designed to mount on the edge of a board with a minimal footprint. The multimode 850-nm wavelength laser can drive a 100 m OM3 ribbon cable. They come in low-profile, pluggable, and surface-mount versions.

One place Reflex Photonics’ device is used is in Amphenol Aerospace’s LightConex connector system. It can be utilized as a blind mate optical connection for the VPX VITA 66 optical backplane standard, like this one from Elma Electronics (Fig. 2).

The Elma backplane uses multiple alignment mechanisms. There are the metal rods on either side of the connectors from each board, a plastic tab in the middle of the LightConex socket, and a pair of tiny rods on the device that provide finer grain alignment. The system is designed to handle multiple reconnections.

The Reflex Photonics interface can also be used on the front panel as well. Interface Concept is using the LightABLE technology in its optical IC-OPT-FMCPa FMC board (Fig. 3). The FMC board uses a pair of Reflex Photonics LightABLE embedded optical modules. It implements the VITA 57.1/57.4 standard to deliver 120 Gbits/ of full-duplex bandwidth. It is typically used as an FPGA front-end processing board.

The compact size of the Reflex Photonics LightABLE modules allows them to be placed in some unusual places like Meritec’s ANSI/VITA 76 standard connectors (Fig. 4). The connector can deliver high-speed signals along with power. The Meritec connector uses the power to drive the LightABLE modules and in turn work with the fiber optic cable plugged into the other end of the Meritec connector.

This approach allows a designer to develop a host system with the ANSI/VITA 76 standard connector and decided what type of technology to connect the host to another node. A copper connection will have a more limited distance but will usually be a less expensive approach. The Meritec connector and fiber cabling would provide the maximum bandwidth and greater distance in addition to significantly reduced crosstalk.

Fiber remains more expensive than copper but it is becoming practical in more situations. It is often the only solution where high-speed, long-distance communication is required. VITA’s standards are only one place where Reflex Photonics’ LightABLE and Amphenol’s LightConex technology is being used. Military and avionic applications have the performance, reliability, and safety requirements in addition to being able to absorb the cost—even as those costs continue to drop significantly. There are many industrial and outdoor applications where this technology can be employed as well.

About the Author

William G. Wong

Senior Content Director - Electronic Design and Microwaves & RF

I am Editor of Electronic Design focusing on embedded, software, and systems. As Senior Content Director, I also manage Microwaves & RF and I work with a great team of editors to provide engineers, programmers, developers and technical managers with interesting and useful articles and videos on a regular basis. Check out our free newsletters to see the latest content.

You can send press releases for new products for possible coverage on the website. I am also interested in receiving contributed articles for publishing on our website. Use our template and send to me along with a signed release form.

Check out my blog, AltEmbedded on Electronic Design, as well as his latest articles on this site that are listed below.

You can visit my social media via these links:

- AltEmbedded on Electronic Design

- Bill Wong on Facebook

- @AltEmbedded on Twitter

- Bill Wong on LinkedIn

I earned a Bachelor of Electrical Engineering at the Georgia Institute of Technology and a Masters in Computer Science from Rutgers University. I still do a bit of programming using everything from C and C++ to Rust and Ada/SPARK. I do a bit of PHP programming for Drupal websites. I have posted a few Drupal modules.

I still get a hand on software and electronic hardware. Some of this can be found on our Kit Close-Up video series. You can also see me on many of our TechXchange Talk videos. I am interested in a range of projects from robotics to artificial intelligence.