Developing wearable applications is not easy. It requires compact devices that tend to be more difficult to prototype. Likewise, designing platforms using new, low power system-on-chip (SoC) devices can be difficult without considering integrating peripherals and developing the software. Compact modules is one approach that developers can take to significantly reduce prototyping time as well as time to market.

Revolution Robotics’ tiny Warp_0x01 module (Fig. 1) is ideal for prototyping wearable platforms that need wireless and computing power. It is also a good platform for DIY projects. I was checking it out at the 2016 Wearables TechCon and IoT TechCon conferences in San Jose (see “Find Out What to Wear at Wearables TechCon”).

The $149 module fits in the palm of your hand and it is about the size of a quarter (Fig. 2). It has a set of small connectors on the back for mating with a carrier board. A large, standard carrier board is available but the module can be matched with a custom board that could be as small as the module itself. This would typically include any additional sensors as well as I/O connectors or buttons as well as a battery. It could easily fit into a large wristband although it might be a bit thick compared to the typical smartwatch.

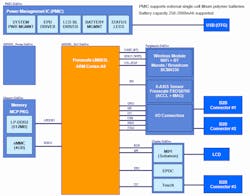

The module is built around NXP’s i.MX6 SoloLite (SL) SoC (Fig. 3) that has a single core ARM Cortex-A9 processor. It also includes a 6-axis accelerometer and magnetometer sensor, 802.11b/g/n WiFi and Bluetooth 4.0 BLE support plus 512 Mbytes of LP-DDR2 and 4 Gbytes of eMMC flash memory. The hardware is an open-source design, making it easier to migrate an application to a custom design. Another big advantage over a platform like Raspberry Pi is that all the parts of the module, including the NXP i.MX6 SoloLite, are readily available in large or small quantities.

The three headers provide access to most of the I/O including MIPI support as well as a touch interface and an EPD (electronic paper display) e-paper interface. The latter provides access to very low-power displays that require no power if the display is not changing. The challenge is getting your hands on an e-paper display that matches your requirements. They are available but there are fewer options compared to LCDs.

The system is suitable for running higher performance operating systems like Linux and Android. This meshes well with the wireless supported provided by the module.

The carrier board (Fig. 4) provides access to the module’s wired interfaces including JTAG support. It has connectors for USB and displays.

The Warp module eliminates a lot of the hardware design necessary for wearable prototypes. Its support for EPD displays is somewhat unique and this low power display technology can make a big difference in wearable applications. The ability to run Android and Linux puts it in the higher end category while maintaining low power requirements.

About the Author

William Wong Blog

Senior Content Director

Bill's latest articles are listed on this author page, William G. Wong.

Bill Wong covers Digital, Embedded, Systems and Software topics at Electronic Design. He writes a number of columns, including Lab Bench and alt.embedded, plus Bill's Workbench hands-on column. Bill is a Georgia Tech alumni with a B.S in Electrical Engineering and a master's degree in computer science for Rutgers, The State University of New Jersey.

He has written a dozen books and was the first Director of PC Labs at PC Magazine. He has worked in the computer and publication industry for almost 40 years and has been with Electronic Design since 2000. He helps run the Mercer Science and Engineering Fair in Mercer County, NJ.

- Check out more articles by Bill Wong on Electronic Design

- Bill Wong on Facebook

- @AltEmbedded on Twitter