Can AI-Driven CAD Tools and PCB Stators Help Manufacturers Move Past Winding Lines?

This article is part of the special report below.

What you’ll learn:

- Smarter motor design through AI-driven software.

- Motor designs from CAD to production in hours.

- Eliminating winding lines with PCB stators.

The electric motor industry is undergoing a fundamental transformation. As CEO of ECM PCB Stator Tech, I’ve seen firsthand how artificial intelligence and digital manufacturing are reshaping what’s possible.

At ECM, we’ve built a platform that replaces copper winding lines with printed circuit boards. We’ve done this by embedding intelligence at every level of design and production. This article is about how AI-driven tools like ECM’s PrintStator platform are empowering companies to move beyond legacy winding lines and embrace vertical integration, custom design, and radically faster workflows.

Smarter Motor Design Through AI-Driven Software

ECM’s PrintStator platform uses advanced proprietary machine-learning algorithms to optimize motor geometry, performance, and thermal efficiency based on user specified inputs. This isn’t static code. It’s constantly improving.

With every prototype we build, we feed real-world performance data back into the system, strengthening its predictive fidelity and refining optimization paths. The result is a smarter tool that learns from what we design and test, helping us and our partners design better motors every time (Fig. 1).

And we’re not stopping there. We’ve begun developing a fully secure, AI-powered motor design assistant. It will guide engineers through the development process with intelligent suggestions, highlight design tradeoffs, and surface similar challenges and solutions from past projects. The goal is to make expert motor design more accessible, more iterative, and more scalable.

From CAD to Production in Hours

This software is transforming not only what we can design, but how fast we can do it. Our latest PrintStator release, v8.3, delivers sub-2-second simulations and complete electromagnetic motor models in moments. That means instead of waiting weeks for simulations, our engineers can explore new designs and validate them in near real time.

More importantly, the platform goes beyond electromagnetic modeling. It also generates CAD- and CAM-ready housing designs, which we’ve used to move from concept to machined parts in just a few hours. This combination of speed and precision gives teams the ability to iterate rapidly and build hardware that’s actually tailored to their product, not forced to work around a legacy off-the-shelf motor (Fig. 2).

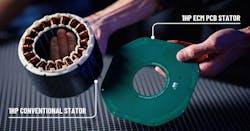

Eliminating Winding Lines with PCB Stators

Once the design is finalized, the production path looks very different than it was in the past. Our motor designs use PCB stators—flat, printed-circuit-board structures instead of wound copper coils. This means there’s no winding line, no coils, and no specialized machinery. Instead, we send our stator files to any global PCB fabrication facility and receive production-ready components in return (Fig. 3).

This unlocks an entirely new level of flexibility. Because PCB fabrication is a global industry, stators can be manufactured anywhere. That makes localized production, reshoring, and even on-site assembly lines viable for companies that once had to outsource motor manufacturing entirely. We’re seeing increasing numbers of partners move from buying off-the-shelf motors to assembling their own PCB stator motors in-house, in essence Motor OEM franchising via ECM’s PrintStator SaaS platform

A New Model of Vertical Integration

By eliminating the complexity of winding and integrating design and manufacturing, we’ve helped companies vertically integrate their motor production from CAD to prototype to production. This gives our partners more control over their supply chains, allowing them to bring motor development and assembly closer to their core operations. This has major implications.

It reduces lead times. It mitigates tariff exposure. And it lets companies design motors around their product instead of the other way around.

I believe this approach is especially powerful in sectors where motors are central to performance—HVAC, robotics, mobility, aerospace. Our partners are building smarter, quieter, and more efficient products because the motor is now part of their core design process (Fig. 4).

Goodbye Off-the-Shelf

One of the most exciting outcomes of all this is that we’re finally able to enable partners to say goodbye to off-the-shelf motors. Instead of picking from a catalogue and compromising on form factor, or efficiency, our partners use PrintStator to generate application-specific designs, each one optimized for the exact use case, from a robotic arm to a high-efficiency pump.

What once took months and a team of motor engineers can now be done in hours. And every prototype makes the system smarter for the next project (Fig. 5).

Conclusion

As we continue developing AI-powered tools and motor technologies, we’re seeing a future where companies no longer rely on legacy supply chains or fixed product catalogs. They’ll be able to design what they need—when they need it—and produce it on their terms.

At ECM, our goal is to help partners break free from the limitations of traditional motor design and create the most efficient, flexible, and scalable electric machines in the world. And it all starts by saying goodbye to the winding line.

Read more articles from this special report

About the Author

Brian Casey

President and CEO, ECM PCB Stator Tech

Brian Casey is an expert in the energy and technology industry with over 30 years of experience. This includes leading two companies from growth-stage, to scale, to acquisition.

As the founder and CEO of sustainable energy firm, SourceOne, Brian was responsible for the overall management and technical efforts of the company. He successfully raised equity investments, targeted, and acquired complementing business from a Fortune 500 company, and developed a uniquely qualified commercial, private utility offering.

Under his direction, SourceOne created and implemented award winning, sustainable energy projects for its customers and secured multi-million-dollar energy efficiency and infrastructure contracts within the private and public sectors.

Veolia Environnement S.A. acquired SourceOne in April of 2007. Brian continued to grow SourceOne over the next several years, realizing double-digit growth in revenue and earnings and delivering significant shareholder value.

From there, he co-founded SourceGreen, an industrial scale solar energy development company that successfully created 8 MW of renewable solar energy within the state of Massachusetts. NextSun Energy acquired SourceGreen in 2013.

In his role as President and CEO of ECM PCB Stator Technology, Brian has driven ECM’s development as a global electric motor design and SaaS company. ECM pairs advanced Motor CAD and patented PCB Stator—printed circuit board—technology to create next generation electric motors that are lighter, quieter, and more energy and space efficient across a broad range of use cases.

He has led the adoption of ECM’s technology by multiple partners across a broad range of verticals: HVAC, Consumer Electronics, E-Mobility, Fitness, Medical, Robotics, Renewable Energy, Aerospace, Defense, and more.

Brian currently serves on the board of Hubbell Power Systems owned Cantega Technologies—an industry-leading software platform for the manufacture of dielectric polymer products that serve the electric utility industry.

He holds a Bachelor of Science Degree in Electrical Engineering with a concentration in Power Systems & Delivery from Northeastern University.