Beyond Patching: Non-Stop Security for Semiconductor Fabs

What you'll learn:

- How to adapt current approaches to vulnerability assessment of operational technology (OT) environments.

- How to identify risks in semiconductor manufacturing tools without triggering outages.

- How to implement secure assets on the fab floor that can’t be patched or rebooted.

- Strategies for fixing security issues based on operational risk and network exposure.

- Methods for incorporating supply-chain security standards into the planning and procurement phases.

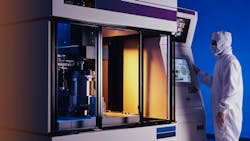

Semiconductor manufacturing is defined by a unique tension between the need for nonstop, predictable operation and the challenges of maintaining equipment that often remains in use for decades at a time. Consequently, when it comes to fixing security vulnerabilities, traditional patch cycles rarely fit the realities of a fab floor.

In a fab, a single reboot can interrupt a stable recipe, halt a multi-hour chamber process, or disrupt a complex upstream and downstream workflow. The cost of these disruptions often outweighs the risk of the vulnerability itself. In this situation, managing vulnerabilities can’t be treated as a standard IT routine. It’s a continuous risk-management discipline that’s critical to safe and reliable production.

As a result, adopting a lifecycle approach is the way to go. That means understanding vulnerabilities, assessing exposure, applying compensating controls, and integrating risk decisions into daily operations. When done correctly, this approach allows fabs to reduce the likelihood of disruption while strengthening resilience against an expanding threat landscape.

Why Vulnerability Management Matters in Chip Fabs

Risk in OT environments — the realm of industrial automation — begins when a threat agent finds a path to exploit a weakness. In manufacturing, that weakness is often an unpatched system, an outdated operating system, a misconfigured service account, or an unsecured remote-access method.

If exploited, the impact isn’t limited to data loss. Every asset on the fab floor represents a significant investment in dollars and cents. A single robot arm can cost in the range of $100,000, while the most critical tools in semiconductor fabs such as EUV lithography systems may run into hundreds of millions of dollars each. Even a minor outage can ripple through the whole line.

Exposure increases when these assets are reachable from external networks or from less trusted zones. The combination of aging equipment, long-term vendor dependencies, and highly interconnected workflows creates a concentrated risk area. Many tools run operating systems that no longer receive patches, yet they remain indispensable to production.

Embedded PCs typically run generic OS versions that can’t be upgraded without jeopardizing tool stability. Performance requirements further limit software changes, leaving large portions of the environment vulnerable.

These conditions make vulnerability management a continuous operational responsibility rather than an occasional technical task.

Understanding Risk Assessment in the World of OT

The main steps in assessing vulnerabilities and other risks in manufacturing, as outlined by NIST, come down to “frame, assess, respond, and monitor.” The four-part process, presented in the NIST SP 800-82 Rev. 2, is focused on evaluating threats, vulnerabilities, and impacts in industrial control environments, including SCADA systems, distributed control systems (DCS), and programmable logic controllers (PLCs).

The latest revision, NIST SP 800-82 Rev. 3, expands this view by introducing OT Cybersecurity Program Development as the starting point. Leadership support, clear ownership, and integration with enterprise security are established before undertaking formal risk assessment. The new revision adds prescriptive guidance for operational tasks such as maintenance planning, incident handling, and recovery coordination, all aligned with the NIST Cyber Security Framework.

The same four-step process remains, but it’s supported by detailed mappings to a risk-management framework. This includes guidance for supply-chain issues that frequently affect semiconductor operations. Such a shift reflects how risk is managed in a fab. The emphasis is not only on identifying vulnerabilities, but also on embedding risk practices into routine operations.

Separately, the SANS Institute has also outlined a seven-phase approach to vulnerability assessment that can be useful for understanding what needs to happen to keep chip fabs secure without interrupting normal operations. These phases include engagement planning, intelligence and threat modeling, discovery, scanning, validation, remediation, and reporting. In OT environments, the goals remain the same, but the methods require adaptation.

Staying Ahead of Security Threats to Semiconductor Fabs

The engagement planning phase aligns closely with the program development concepts in NIST SP 800-82 Rev. 3. Before any assessment begins, clear objectives, boundaries, and resource allocation must be defined.

In semiconductor manufacturing, planning incorporates supply-chain security expectations such as SEMI E187. Tools should arrive with supported operating systems and documented patch procedures. Secure transmission protocols must be used to prevent the introduction of vulnerabilities during transport.

>>Check out the other articles in this series, and this TechXchange for similar articles and videos

Pre-shipment malware and vulnerability scanning lowers supply-chain risk. And hardening guidelines prepare assets for safe deployment once they arrive at the fab.

Planning should also define the expected outputs and key performance indicators for the assessment. Clear reporting metrics help leadership evaluate results and support ongoing investment.

These preparations are strengthened by intelligence and threat modeling. According to the SANS State of ICS/OT Security 2025 report, most organizations rely on vendor-provided intelligence feeds. Many participate in information-sharing groups as well, to gain early insight into vulnerabilities that could affect their operations.

Threat modeling in OT focuses on live operational environments rather than software development. A useful reference is the SANS ICS Layered Threat Modeling, which works by placing potential threats within an operational context across multiple layers.

The objective is to understand how a threat can move, what it can reach, and how it interacts with core processes. This approach helps teams determine where vulnerabilities matter most and where compensating controls are necessary.

Understanding What’s at Risk and What’s Vulnerable in the Fab

The next phase, asset discovery and scanning, is fundamental to understanding risk. Historically, this has been difficult in semiconductor environments due to isolated networks and the large number of specialized tools from many vendors. Today, passive discovery solutions make it possible for organizations to build accurate inventories without active probing.

OT-aware scanning tools identify vulnerabilities by analyzing network traffic and protocol behavior. These methods avoid aggressive scanning techniques that can disrupt sensitive devices.

Many OT systems aren’t designed to withstand typical IT scanning behaviors such as malformed packet injection or exploit simulation. For this reason, passive or low-impact scanning is preferred.

In OT environments, complete visibility is difficult to achieve. The goal is to identify critical assets that influence safety, production, or business continuity. Once those assets are known, teams can prioritize risk decisions around them.

Validation, the fourth step in this approach, determines how vulnerabilities affect operations. It’s common to find large numbers of issues during an OT vulnerability assessment. This volume is expected and should not be treated as a simple numerical problem. More than 40,000 common vulnerabilities and exposures (CVEs) were uncovered in 2024 alone, including hundreds with maximum severity scores. Counts and scores alone don’t define risk.

OT environments require risk-based prioritization. Factors such as exploit availability, network exposure, and asset criticality guide decisions. Vulnerabilities that have active exploitation in the wild, or that reside on assets reachable from untrusted environments, rank highest. Such an approach ensures that the most relevant threats are addressed first.

The Stakeholder Specific Vulnerability Categorization (SSVC) model can assist by incorporating environmental context into response decisions. This helps teams determine which vulnerabilities require immediate action and those that can be deferred with appropriate controls.

Fixing Vulnerabilities in Fabs and Other No-Downtime Environments

Remediation in OT is rarely straightforward. Unlike IT, production systems can’t undergo frequent patching or reboots. In fact, many assets can’t be patched at all. Instead, remediation relies on a combination of protective controls that reduce exposure.

Segmentation limits communication pathways and prevents lateral movement. Allowlisting ensures that only approved processes can run on engineering workstations or tool controllers. Device control policies restrict the use of removable media, and protocol filtering limits commands to only those required for normal operation. Remote access is governed through controlled pathways with strong verification and session monitoring.

When patching isn’t possible, virtual patching becomes critical. Deployed at strategic control points, virtual patching can block exploit attempts targeting known vulnerabilities. These controls enable fabs to reduce risk without interrupting production and provide time to evaluate permanent fixes during planned maintenance windows.

The final phase, reporting, involves documenting validated results, ranking vulnerabilities by risk, and presenting findings to stakeholders. Reporting should highlight where compensating controls are applied, where immediate remediation is required, and where long-term improvements are recommended.

Clear reporting helps leadership understand current exposure and supports informed decisions about resource allocation, maintenance planning, and future cybersecurity investments.

Building a Sustainable Vulnerability Management Lifecycle

For fabs, vulnerability management isn’t an occasional scan for security issues. It’s a continuous lifecycle aligned with the operational rhythm of the plant. Sustainable programs include:

- Using OT-native discovery solutions to keep asset information current.

- Scheduling low-impact scanning and analysis that fit production constraints.

- Applying segmentation, virtual patching, and access governance as compensating controls.

- Coordinating with vendors to obtain validated patches and safe deployment procedures.

This lifecycle brings structure and predictability to vulnerability management while supporting reliable operations.

Ultimately, patching alone can’t address the unique challenges of semiconductor manufacturing. A lifecycle approach built on risk assessment, OT-aware scanning, compensating controls, and clear reporting provides a practical path forward.

By adopting structured vulnerability management practices and aligning them with industry standards such as SEMI E187 and the guidance in NIST SP 800-82 Rev. 3, fabs can strengthen their security posture while maintaining stable and continuous production.

References

NIST SP 800-82 Rev. 2. Guide to Industrial Control Systems (ICS) Security

NIST SP 800-82 Rev. 3. Guide to Operational Technology (OT) Security

SEMI E187 - Specification for Cybersecurity of Fab Equipment

SANS. State of ICS/OT Security 2025

SANS. ICS Layered Threat Modeling

CISA. Stakeholder-Specific Vulnerability Categorization (SSVC)

>>Check out the other articles in this series, and this TechXchange for similar articles and videos

About the Author

Steven Hsu

Vice President, Evangelism, TXOne Networks

Steven Hsu has over 27 years of experience at the intersection of cybersecurity, software development, and quality management. His career includes leadership roles in engineering, product planning, and global business development, most notably as Senior Director at Trend Micro. Today, he focuses on cybersecurity management frameworks and strategic planning, helping organizations implement practical approaches to security.