Motor Efficiencies

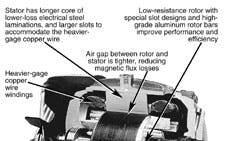

High-efficiency motors are built to reduce motor energy loss. Improvements in several areas, Figure 20, increase motor service life:

- Larger-diameter wire, increasing the volume of copper by 34 to 40%. This change reduces copper losses that result naturally from current passing through the copper-wire windings.

- Larger wire slots to accommodate larger wire. This reduces the amount of active steel in each steel lamination.

- Longer rotor and stator core to compensate for the loss of steel and the resultant need to add more laminations.

- High-grade silicon steel laminations approximately 0.018 in. thick, having an electrical loss of 1.5 W/lb. The chemical makeup and thinner gage of the laminations, plus a coating of inorganic insulation on each piece, reduce eddy current losses. Special annealing and plating of rotor and stator components and use of high-purity cast aluminum rotor bars reduce hysteresis losses.

- Higher-grade bearings reduces friction loss.

- Smaller, more efficient designs reduce windage losses in fan-cooled motors.

- Tighter tolerances and more stringent manufacturing-process control reduce losses from unplanned conducting paths and stray load phenomena.

These design changes also result in cooler running motors. Cooler operation lengthens a motor's service life in two ways. For every 10° C reduction in temperature, motor insulation life doubles; high-efficiency motors tend to operate 10 to 20° C cooler than standard-efficiency motors.

The motors that must meet the new efficiency levels include: All motors made in or exported to the U.S., including all motors sold as part of a piece of equipment; general purpose motors; motors rated from 1 - 250-hp; T-Frame; single speed; foot mounted; polyphase; NEMA designs A & B; continuous rated; 230/460 volts; constant 60-Hz frequency.

Exceptions include special purpose and definite purpose motors.

Efficiency ratings will be on the motor nameplate. A recent efficiency labeling standard requires that premium- efficiency motors carry the NEMA nominal efficiency rating on the label.