The minicomputer: machine with an endless future

What You'll Learn

- What was the state of minicomputers in 1970?

- How minicomputers were being used at the time.

- How engineers and programmers were dealing with minicomputers.

The minicomputer industry is the fastest growing segment of the fastest-growing business in the world.

This article was the cover story in Electronic Design published in April 1970, Vol. 18, No. 9. There is a matching article by Senior Content Director William Wong entitled Now and Then: Minicomputers puts this historical article into context.

This statement by the director of marketing of a minicomputer manufacturer-Allen Z. Kluchman of Data General Corp., Southboro, Mass. - sums up the impact of an idea that has been kicked around in the computer industry for six or seven years but only began to bear fruit two years ago.

- What is a minicomputer

- A challenge to time-sharing

- Time-shared minicomputers offered

- Up-to-date software needed

- Minicomputers to concentrate data

- First used in laboratories

- Interactive experiments made possible

- Hard-wired logic replaced

- Minicomputer cuts design costs

- Microprogramming vs macroprogramming

- Minicomputers invade the factory

- Computers test other computers

- Instant trouble-shooting possible

- 'Family trees' can be built

- A boon to hospital care

- End user vs OEM

- Manufacturers stake their claims

- Mainframes are only one aspect

More Now and Then Articles

What is a minicomputer

The minicomputer's name comes. from its small size, but its most significant feature is its relatively low cost. Doubling its physical size probably would not affect the rising sales curve drastically; doubling its price would have a strong adverse effect. All of the applications, therefore, reflect the fact that it can penetrate markets never before entered by computers.

The computer industry is now turning out its third generation of large machines. Today's minicomputer has the computing power of the first-generation Univac I, but it is rapidly growing beyond that benchmark. New developments in large-scale integration (LSI) of semiconductors, either already here or just over the horizon, will accelerate that growth.

The applications of the minicomputer run the gamut of the computer business. It is used alone to solve scientific and engineering problems. It gives the small businessman the ability to automate his payroll, billing and inventory control operations. It is used to control the operations of process industries and manufacturing plants. It replaces hardwired logic in switching systems. It performs as a data concentrator for data-communications systems. It operates test lines in manufacturing and reads, records and reduces data for engineers in development laboratories.

It maintains the medical and financial records of patients in hospitals. The list is endless. In the words of one manufacturer: "The market grows with each inquiry from a prospective customer."

Some of the minicomputers are general-purpose and can be adapted to any number of different applications. These machines give up some computing power and speed for their flexibility, but the big demand for them, and consequently the longer production runs and higher sales, make it possible to cut prices.

Other minicomputers are aimed at specific markets and are more specialized. These machines have higher performance and probably higher initial costs.

Some of these generalizations do not take into account the cost of peripheral equipment, which makes the minicomputer a computing system. They are impressions gained from talking to many manufacturers, however.

Electronic engineers have three areas of contact with the minicomputer. They are the design of the machine, its component parts and its peripheral equipment; the use of the machine as an adjunct to other engineering endeavors, such as problem-solving or as a laboratory tool; and the engineering of applications for customers who have a specific task to perform. All include hardware and software design.

For an engineer to perform these functions, he must be aware of the characteristics and limitations of the machines.

Let us, therefore, take a look at some of the many possibilities. The engineer is probably most familiar with computers used to aid in the design of circuits and equipment.3 Can the minicomputer operate in this area?

A challenge to time-sharing

Here it is a question of minicomputers vs commercial time-sharing services, and the stand that one takes depends strongly on the speaker's affiliation. The user's point of view is "show me." The time-sharing service or the manufacturer of computers for use in commercial time-sharing has little but disdain for the minicomputer. The minicomputer manufacturer echoes Eliza Doolittle: "Just you wait . .. . "

The issue, of course, is how to get more computing power for the dollar. The time-sharing service is weighted down by the cost of communication lines, over which it has no control, and terminal charges while the user is on-line but not computing. These two costs can amount to half or more of the total charge for the use of a time-shared computer.

The big machines that the commercial services offer, however, can do a great deal of computing that the minicomputers cannot. The reason: the very large memories that the big machines have. Complex programs cannot be stored in small memories. Richard McNair, computer scientist of XDS, El Segundo, Calif., a supplier of computers to many time-sharing services, refers to this when discussing computer-aided design (CAD) for circuit programs. He says: "The size of the programs that are being used in CAD are such that the minis cannot handle the number of program statements required. CIRC de has 7000 statements, and CIRC ac and SCEPTRE have over 15,000. Some things can perhaps be put on a minicomputer instead of in commercial time-sharing, but I don't know what. I think that time-sharing can do most CAD better."

XDS's manager of product marketing, Lawrence Israel, has a different reason for believing that minis pose no serious competitive problem for time-sharing services. He says : "The running costs of a self-contained in-house computing system-including maintenance, setting up and choosing auxiliary and peripheral equipment-have an adverse effect on cash flow that use of a time-sharing service does not."

Israel also points out that time-sharing services supply more than just time on a computer. They are large suppliers of software to their customers. The user of an in-house computer system must either buy or supply his own software. Israel foresees minicomputers restricted to data communications, control and laboratory system applications.

Time-shared minicomputers offered

Three of the largest manufacturers of minicomputers see few restrictions on the use of their machines. They are Digital Equipment Corp. of Maynard, Mass.; Hewlett-Packard, Palo Alto, Calif., and Varian Data Machines, Newport Beach, Calif. Both Digital Equipment and Hewlett-Packard now offer minicomputers for inhouse computing applications, and Varian is planning to offer one shortly. These systems adopt one feature of their competitors: they are interactive time-shared computers. Usually as many as eight remote terminals can be linked to one minicomputer central processing unit.

Minicomputer manufacturers refute the antimine arguments one by one. The minicomputer manufacturer can choose, set up and maintain a system for a user. The system can be leased, so that the customer need not make a capital investment. The manufacturer can make software available-perhaps not free, but neither is a time-sharing service's software strictly free either. Time-sharing service charges include the cost of software. The only objection that the minicomputer manufacturer cannot answer is that the computing capability and memory size offered by the time-sharing services is larger.

But in one respect the minicomputer can outperform the time-sharing service, according to Zvonko Fazarinc, an engineer with HewlettPackard. He does not design computers, but he does have one available for his use in designing test equipment.

Fazarinc dismisses the small memory as of little importance. His machine has a 16,000-word memory, but he believes that 8000 words are sufficient for most jobs. He concedes that SCEPTRE needs over 15,000 source statements, but he says that SCEPTRE has general-purpose capabilities to make it useful for a wide variety of problems. Fazarinc's circuits have restricted requirements and can be designed with much smaller programs. He says : "We make the program as big as the circuit requires."

A typical problem — the design of a Schmitt-trigger — was run by Fazarinc in CIRCUS, SCEPTRE, SYSCAP and on his mini. The running times were 80, 85, 30 and 35 seconds, respectively — this in spite of the fact that the big programs ran on machines that could multiply 500 times as fast as the minicomputer.

Up-to-date software needed

Another disadvantage of the time-sharing services' CAD programs, according to Fazarinc, is that they are obsolete. They are being maintained on-line only because nothing better is available. Fazarinc calls them obsolete because they are all linear programs with limited nonlinear capabilities. He thinks that the engineer with a nonlinear problem is better equipped to solve it if he has his own minicomputer at hand and can try out his own programs. Fazarinc says: "Linear circuit analysis by computer is a waste of time. It has been done over and over again. If a circuit-analysis program can't do nonlinear problems, it is useless."

Fazarinc is particularly in favor of a minicomputer terminal dedicated to serving one engineer at a time. This permits the use of a program as a substitute for an actual circuit on a laboratory bench. The dedicated computer allows the engineer to study his circuit in depth; to examine its performance at any point. A plotter, or a device as simple as a strip-chart recorder, can be attached to the computer to make hard copies. The low cost of the minicomputer makes such dedicated operation possible.

It is likely that these two strongly opposing opinions-that minicomputers cannot design effectively, on the one hand, and that they will displace commercial time-sharing services, on the other-overstate the case for and against the in-house, stand-alone minicomputer. The future will probably see some compromise in marketing positions.

A projection by the Diebold Group, Inc., a New York management consulting concern, indicates that another rapidly growing segment of the computer industry over the next five years will be in information services. This category includes time-sharing services as a significant component. Diebold says that there is room for both the time-sharing and minicomputers to grow here.

On the lower level of capabilities, the desktop calculator enters as a possible competitor of the minicomputer. Some programmable desk-top calculators have a degree of sophistication that approaches that of the minicomputer. But the price does, too-and that is the kicker. The most elaborate desk-top calculators, which are completely self-contained machines (they require no auxiliary equipment to perform their functions, however limited), can be installed on an engineer's desk for about $5000. The addition of such frills as a printout and a plotter can double this figure. A time-shared minicomputing system with eight terminals can be installed for $25,000 to $50,000. Each terminal costs as little as $3000 and is, therefore, competitive with the desk-top calculator.

The likelihood is that the winner in this particular showdown will be the mini. Sophisticated desk-top calculators will be forced to become more simple (and cheaper) or more elaborate — until they, too, are minicomputers.

The problem-solving minicomputer will carve out a niche for itself between the successors of the adding machine on one side and sophisticated commercial time-sharing services on the other. It is likely that none of the three manufacturing categories will suffer too badly in this competition, because each will grow in its own area as the market expands.

Minicomputers to concentrate data

Communication of data over leased telephone lines is very expensive. It is, in fact, one of the major cost items in the use of commercial timesharing systems. One reason for the high cost is that most user terminals are standard teletype or electric typewriters that operate at low data rates. The ordinary voice-grade telephone line is capable of transmitting data considerably faster than the average terminal can handle it.

Other factors enter into the cost of using telephone lines in time-sharing. Users operate in an on-line mode when, in reality, they are only pondering their next step. A user who is attempting to decipher the computer's diagnostic statement while on-line is wasting valuable telephone time. High-speed terminals can transmit data more rapidly, but they cannot speed up the operator of the terminal.

Because of these considerations, the minicomputer will become a partner of time-sharing in another way: as a data concentrator for both the user and the service. The concept is simple. Use a minicomputer at the output of a terminal to store data being transmitted by the user. The memory in the minicomputer thus becomes a fairly large buffer storage. When all of the information has been delivered by the terminal to the minicomputer, the central time-shared computer can be accessed and the data transmitted at high speed in a brief time. The process is reversed for data transmission from the central computer.

When a time-shared computer user has many terminals at one site, the technique is even more useful. The user in this case can be connected continuously to the central computer through only one data line. All of the terminals feed into the buffer storage in the minicomputer, which in turn transmits the data over the single line. In addition to the computations being timeshared, the data transmission is also time-shared with a consequent savings in communication costs.

Engineers and scientists were among the first to conceive of the possibilities of small computers, and they provided the impetus that led to the development of the minicomputer.

At first, the computer was used to record data and to perform elementary operations on it. As the technique became more elaborate, the minicomputer was required to perform at higher and higher levels, until the current capabilities were reached. Now, engineering measurements that require many days or weeks of conventional data-taking by technicians and computation by engineers can be completed in hours.

The key to the technique is to make use of measuring instruments as peripherals to the minicomputer. The instruments must either have computer-compatible digital outputs, or, if they are analog instruments, they must have a suitable analog/ digital converter as an interface to the computer.

Interactive experiments made possible

One unique consequence of the minicomputer in the laboratory is the practicality of interaction between the engineer and the experiment. The computer is operated on-line. The results of an experiment are available in real time, so the experimenter can return to the set-up, modify it and obtain new results-all in less time than it previously had taken to copy down the readings of the instruments.

The practicality of using a minicomputer in the laboratory to perform as an on-line controller for the taking of data and as a computer for the reduction of data depends on many factors. They include the kind of data being taken and the speed at which it is read; the amount of computation needed to reduce the data to usable form; the need for modification of experimental set-ups as the experiment proceeds; and the quality and quantity of hardware and software necessary to get the experiment going in the first place.

The applications of the technique cover the electromagnetic spectrum and then some. Conventional electrical measurements-including voltage, time and frequency responses, spectrum analysis and the like-are commonplace. More abstruse applications include pulse-height measurements in high-energy physics, nuclear magnetic resonance, laser and maser phenomena and mass spectrometers. On the less sophisticated end of the list, the engineering and scientific applications merge with those of the test line and the factory. As older techniques become more familiar, they are adopted by the production department and new, sophisticated devices replace them in the science laboratories.

Hard-wired logic replaced

Hard-wired logic has been used for many years in many forms. Before logic terminology became common and before electrical engineers were aware of Boolean algebra, designs embodying these techniques were created with relays. One such application was an automatic elevator control. Later hard-wired circuits followed in the wake of electronic technology: vacuum tubes, thyratrons, semiconductor diodes, transistors.

There are three basic operations in hardwired logic: interlocking, sequencing and selection. All of these can be performed with minicomputers. The sensing elements, whether they be switches, photoelectric devices, proximity devices or any other detector, become the peripheral devices for the computer. The interconnection of the logic that determines the mode of operation becomes either a computer program '(software) or a microprogrammed read-only memory (firmware).

Minicomputer cuts design costs

The major reason for using a minicomputer to replace hard-wired logic is a reduction in cost. Each job requiring hard-wired logic is unique. The traditional approach has been to design the logic circuits — a process that requires the attention of engineers and draftsmen. Then it is necessary to procure the material, design and fabricate circuit cards, wiring and racks, and to manufacture and test the resulting product. The costs in this process can be considerable, even with relatively simple systems, because of the high labor skills involved.

Until the prices of minicomputers dropped to their present levels, the use of a computer as an alternative to hard-wired logic was not even considered. Now, however, it is possible to eliminate all of the labor costs of the design and manufacturing phases by using a computer (Fig. 2). This does not imply that the use of the computer is free. There is the little matter of programming, either micro or macro, which erode a considerable portion of the savings. In some cases, it may cost more to program a computer than to design and build hard-wired logic. But the computer brings additional benefits.

One serious problem in the use of hard-wired logic is that the processes to be controlled are rarely specified fully at the time the logic is being designed. The engineers must make some assumptions that become part of the design. If the assumptions are not consistent, or if the process itself changes after the logic is designed, the logic must be modified after it is built. Such modification requires more engineering time, more documentation and rewiring, and this can easily double the cost of the original design.

But with a computer program, the modifications are made to the software, and this is a much simpler, and less costly and less time-consuming operation.

After the control system is put into operation — in a chemical plant, say — the plant may find it necessary to alter its operations. With the minicomputer, the alteration can be made by modifying the software again. With wired-in logic, the hardware must be ripped out and completely redesigned.

Maintainability is also improved with use of the computer, because the machine is a standardized component with a recognized maintenance procedure. The repair and maintenance of hard-wired logic requires the attention of a trained technician. Computer repairs can be performed, in most cases, simply by replacing standard circuit card~ until the device is again in operation.

Minicomputers invade the factory

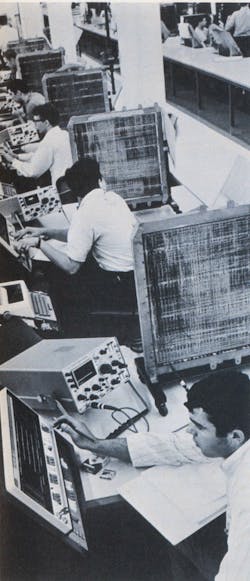

Minicomputers are about to become standard equipment in the modern factory (Fig. 3). By replacing hard-wired logic, they can function as machine and process controllers. They can also exercise supervisory control over a series of machines and processes. Probably the most significant new application is in running test lines at both the incoming inspection and final test points.

The use of computers in factories is expanding into smaller and smaller plants. These applications involve the control of inventory, cost and labor units. Minicomputers can perform the entire function in small factories and can feed information into central computers in larger factories.

Numerical control has been another expanding area of computer use in manufacturing. Until recently, only large computers were available, so machine tools had to be controlled in groups to take advantage of the computer's capacity. Now the smaller machines allow integral computers to be installed on machine tools, with an important improvement in flexibility of use.

Computers test other computers

One of the most interesting minicomputer applications got its start not long ago when Digital Equipment Corp. began to use its own products to test its output. The Digital plant now probably has the highest concentration of test minicomputers anywhere.

Every stage of manufacturing is tied to a computer test line. Logic modules are tested through all of their functions in a small fraction of the time that the same job would take if done manually. As an added plus, a hard copy of the test results is immediately available for each module. If the unit passes, the printout is a record of the test; if it doesn't pass, the printout describes the repairs that are needed.

At higher levels of assembly, the computer controlled test line performs similar, but more involved functions. Final test of virtually all minicomputers of any manufacture. is now carried out by a companion unit. Programs are written to exercise all computer functions and to supervise environmental testing, since repeated heat soaks are a standard procedure in the quality-assurance procedure.

Manufacturers of other products also rely on automated test lines. Steel mills that produce tinplated sheets for cans use sensors connected to minicomputers to detect flaws in the plating. A large roll of finished sheet cannot be scrapped because of a few pin holes in the surface; neither can the flawed material be used for tin cans.

The solution is to mark each flaw with paint as it is detected, so it can be removed at the canning plant. Simultaneously a printout of the location of each flaw is made by the computer. The printout becomes a permanent record of the roll of sheet and is attached to it when it is shipped. The record is also useful as a check on the plating process itself.

Test and manufacturing can be combined, as in an installation described by Computer Automation, Inc., Newport Beach, Calif. The controlled process is the trimming of a resistor to a high tolerance. The resistance is measured and fed into the minicomputer, which in turn controls a laser beam that burns away resistor material in precisely controlled increments. The process continues until the resistor meets the required tolerance.

Instant trouble-shooting possible

Diagnosis and repair of defective equipment is another related application. General Automation, Inc., Orange, Calif., has some computers attached to microphones and spectrum analyzers to monitor the performance of machinery (Fig. 4). The computer performs a frequency scan and determines the spectrum of the sound. A defective part like a dry bearing has a different spectrum from a good one. This technique is capable of wide use (see "Curing Engine Failures Before They Occur," ED 7, April 1, 1970, p. 30).

The auto industry is toying with the idea of using minicomputers in its service organizations to speed the repair of cars and to help overcome the shortage of trained mechanics. The ingenuity of engineers in adapting sensing instruments to interface with minicomputers will rapidly expand. this area of application.

'Family trees' can be built

Closely related to both factory operation and data concentration is the use of hierarchies of computers to oversee intricate operations. The minicomputer, because of its small size, low cost and ruggedness, is installed at the lowest level of the hierarchy. It can control the unit operations of a plant. It can also be installed as a data concentrator for time-shared terminals.

The minicomputers then communicate with a larger time-shared computer that performs computations and data reduction. This machine may also issue production orders to the computers in charge of unit operations. A larger central data processing computer is the highest level in a plant. All financial, production and cost data finally arrive at this machine for disposition.

Thus the entire record-keeping and operational supervision of a large plant can be kept under the constant surveillance of one or more computers and data processors. The ability of hierarchal computer control to display this omniscience has important ramifications for all levels of corporate management.

Lower management's functions will probably be diluted, while higher management will be strengthened. Overall control will be more easily maintained. The effects of miscalculation at the higher levels of decision may, however, prove more damaging.

A boon to hospital care

As engineers move away from the military aerospace area, they will begin to find employment in unfamiliar fields. One of these that possesses a world of electronic riches is the hospital. The minicomputer will increasingly demand more and more electronic expertise in the hospital.

Hospital use of computers is expected to be one of the major growth areas. The reasons are much the same as those in other applications: greater demands for service and fewer trained personnel to provide it. Typical uses for minicomputers in hospitals are in patient care and clinical applications. Further in the future are data retrieval and diagnosis.

Patient care requires the use of sensors interfaced with the computer. A typical installation makes use of blood-pressure instruments, thermometers, respiration and pulse-rate transducers, as well as more elaborate devices like electrocardiographs and electroencephalographs. These instruments feed signals to a minicomputer that has a display unit at a nurse's station. Alarm levels can be set for each patient, to alert the nurses to an impending crisis. Periodic printouts of each patient's readings provide a hard copy for the physician and replace the familiar and traditional hospital chart.

Medications and dosages can be programmed into the computer· to remind the nurse at proper intervals. (A serious problem in some hospitals is incorrect or improper dosage administered by overworked nurses.) With more equipment, the computer can take over control of some types of therapy. Temperature can be maintained; artificial kidney dialysis and certain types of intravenous infusion can be controlled. The list can go on and on.

Minicomputers make all of this possible by being available at low cost. They can be divided among hospital floors in large urban medical centers, and they can be used with equal ease in small rural or suburban hospitals. The engineer may become as important an employee in the future hospital as the medical doctor is now.

End user vs OEM

The design of a computer control is a problem in system engineering. This simple fact has touched off one of the most intense debates in the minicomputer industry. The thesis is: Resolved, control systems are to be sold through OEM (original equipment manufacturer) channels. Manufacturers have taken positions ranging from the affirmative to the equivocal to the negative, with varying degrees of intensity. A look into the background of the thesis can be instructive.

A computer by itself can perform no useful function. At the minimum, it must have input and output devices properly interfaced and system software that directs it to operate. The average user of a control system is not a sophisticated computer engineer (Fig. 5). He is, more likely, a man who wants a job done at minimum cost and maximum effectiveness and who does not care who or what does the job.

The minicomputer manufacturer, at this stage in the development of the industry, is relatively small but innovative. His financial resources, with some significant exceptions, are limited. He has no facilities for manufacturing peripheral equipment, and he has only a small staff capable of writing extensive programs.

A gap therefore exists between the user and the manufacturer that complicates the interchange of information. This gap is bridged by the OEM. The original equipment manufacturer supplies complete operational control systems to the user; he buys the computer from one source and the peripherals from others. He also provides the specialized software and instruction of personnel that is needed by the user.

The OEM performs one more very important task. He broadens the market, by bringing computer control to the attention of prospective users who would otherwise be ignorant of its advantages to their operations.

Manufacturers stake their claims

The marketing strategy adopted by a minicomputer manufacturer depends very heavily on his financial strength. The giants — Digital Equipment Corp., Hewlett-Packard and Honeywell — profess interest in . the user market. The independents, on the other hand, eschew the user and woo the OEM. But the division is not that cut and dried.

Among the giants, Digital Equipment and Honeywell do a sizable business with the OEMs; and some independents are not averse to short circuiting the OEM if a particularly juicy opportunity should come their way. Only Hewlett-Packard seems to have taken an unequivocal stand in favor of selling to the user, and this because of the unique capabilities that the company has in all areas of computation, instrumentation, interfacing and software.

Mainframes are only one aspect

Prospective computer-control customers should not be beguiled by the low prices quoted for minicomputer main frames. A control system consists of the main frame, peripherals, hardware and software interfacing, maintenance and upkeep, and system software. One knowledgeable estimate is that each of the first four items accounts for one-sixth of the system's total cost, and the system software for the remainder.

Therefore the typical minicomputer control system costs in the neighborhood of $60,000. Maintenance and upkeep can present serious problems. No one doubts that peripherals, many with moving parts, can break down, but the reliability of the main frame is a matter of debate.

Curiously, the larger manufacturers stress main frame maintenance more heavily than do the smaller ones. This is not because computers made by big companies are less reliable, but because big companies are more likely to have extensive repair facilities.

Maintenance and repair is not a serious problem for a sophisticated user. The design of all minicomputers is modular, with all components mounted on circuit cards. A minimum of instrumentation can localize a failure, and replacement of a card is simple. It is the unsophisticated user who may suffer seriously from a failure. If he bought his system from an OEM, he must rely on the OEM for service if complete satisfaction is to be expected.

One exuberant exponent of the minicomputer — Data General's director of marketing —remarked recently (conservatively, some in the industry say) that there were 2000 potential applications for the machine. This report has covered about six of them. The others are out there in the field, where inquisitive engineers are busily interfacing small computers to anything that moves.

In the future, there is the possibility of a minicomputer in every kitchen and in every automobile.

In the future, there is the possibility of a minicomputer in every kitchen and in every automobile. What is more likely is that the minicomputer will lose its identity as a breadbox-sized device and will be hidden inside of the equipment it controls. The likelihood of this development is based on maturation of the concept of largescale integration of semiconductors.

Right now, LSI memories are beginning to appear as production items. Memories with 4000 bits on a 1-inch-square chip are now practical. Logic circuits with similar densities are somewhat further off, but they are imminent. LSI will have several effects on the minicomputer (and perhaps also the large computer). It will make all computers much smaller; it will make them cheaper. It may turn the semiconductor manufacturers into computer manufacturers, thereby making them direct competitors of their current customers.

At least one minicomputer manufacturer — General Automation, Inc., of Orange, Calif. — has recognized this threat and has taken steps to hedge its bets. It is selling its computer production as a package with system software; if it is pushed out of the hardware business one day, it will buy the hardware from others and continue to sell software. Others are ignoring the possible threat and staking their futures on the reputations they are developing.

Whatever the future holds for the minicomputer industry, it is certain to be lively, whether from a business or a technical aspect.

References

1. Long, William H., "Invasion of the Minicomputers," Automation, August, 1969.

2. Lapidus, Gerald, "A Look at Minicomputer Applications," Control Engineering, November, 1969, pp. 82-91.

3. Lowenstein, Milton J., "For Design the Program is the Thing,'' Electronic Design, No. 23, Nov. 8, 1969, pp. C8-C19.

4. Penczer, Rudolf E., "Automation in Data Acquisition," American Laboratory, April, 1969.

5. Decastro, Edson D., "What Can You Do With a Minicomputer," Industrial Research, November, 1969.

6. Noonan, Ronald P., "What Kind of Computer for Your Plant,'' Chemical Engineering, June 2, 1969, pp. 114-116.

7. Bailey, S. J., "On-Line Computer Users Polled,'' Control Engineering, January, 1969, pp. 86-94.

8. Bobroff, Dimitry A., "Avoid Pitfalls in Computerized Testing,'' Electronic Design, No. 17, Aug. 16, 1969, pp. 196-201.

9. Young, Neal F., "Distributed Computer Systems," Automation, October, 1969.

10. Kessler, John N., "Where EE and MD Link Up to Prolong Life,'' Electronic Design, No. 4, Feb. 15, 1970, pp. 24-28.

11. "Small Control Computers,'' Investment Research Report, July 31, 1969, Equity Research Associates, New York, N.Y.