Do wooden wind turbine towers make sense?

Visitors to Hannover in Germany can now gaze at the world's first modern wind turbine built on a tower of wood.

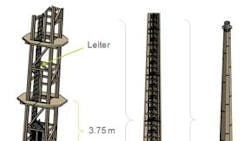

TimberTower, an engineering firm based their, claims the 100-meter-tall turbine it recently erected proves the concept it has for replacing steel wind turbine towers with special laminated wood panels and wooden structural elements. TimberTower starts with a conventional concrete base into which numerous four-meter-long steel rods are cast. The steel bars serve as the base attachment points for the wooden elements. The resulting tower has a profile that is somewhat narrower at the top than the steel towers it is meant to replace.

The claim to fame of the wood construction is both cost and environmental friendliness, say TimberTower spokespeople. The octagonal-shaped tower eliminates the need for about 300 tons of sheet steel. The wood fabrication process is also less energy intense than that of steel making, so there is a saving of about 400 tons of CO2. The wooden tower is said to last as long as a steel version or longer and, of course, can be easily recycled when the time comes.

TimberTower claims there are some logistical advantages to its idea as well. The wood panels and structural elements get assembled on site, so the pieces can be trucked on ordinary flat beds. This avoids a problem with steel tower bases which need a diameter of about 4.2 m to support masts 110 m high. That figure is about at the upper maximum for fitting under road bridges, at least in Germany. So shipping larger steel bases for taller wind turbines can be problematic, TimberTower says.

The 100-m prototype supports a Vensys 77 wind turbine that weighs about 100 tons. TimberTower says it plans to build a 140-m version in the near future.

TimberTower (unfortunately, largely in German): http://www.timbertower.de/