Carbon Nanoballs Boost Efficiency of High Voltage Transmission Cable

Researchers at Chalmers University of Technology (Sweden) have discovered that the insulation plastic used in high-voltage cables can withstand a 26% higher voltage if nanometer-sized carbon balls are added. This could result in enormous efficiency gains in the power grids of the future, which are needed to achieve a sustainable energy system.

The renewable energy sources of tomorrow will often be found far away from the end user. Wind turbines, for example, are most effective when placed out at sea. Solar energy will have the greatest impact on the European energy system if focus is on transport of solar power from North Africa and Southern Europe to Northern Europe.

"Reducing energy losses during electric power transmission is one of the most important factors for the energy systems of the future," says Chalmers researcher Christian Müller. "The other two are development of renewable energy sources and technologies for energy storage."

Together with colleagues from Chalmers University of Technology and the company Borealis in Sweden, he has found a powerful method for reducing energy losses in alternating current cables. The results were recently published in Advanced Materials, a highly ranked scientific journal.

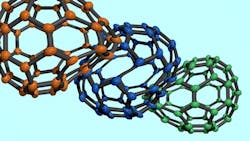

The researchers have shown that different variants of the C60 carbon ball, a nanomaterial in the fullerene molecular group, provide strong protection against breakdown of the insulation plastic used in high-voltage cables. Today the voltage in the cables has to be limited to prevent the insulation layer from getting damaged. The higher the voltage the more electrons can leak out into the insulation material, a process which leads to breakdown.

Figure: Wind turbines are most effective when placed out at sea. Photo courtesy of Lina Bertling.

It is sufficient to add very small amounts of fullerene to the insulation plastic for it to withstand a voltage that is 26 per cent higher, without the material breaking down, than the voltage that plastic without the additive can withstand.

"Being able to increase the voltage to this extent would result in enormous efficiency gains in power transmission all over the world," says Christian Müller. "A major issue in the industry is how transmission efficiency can be improved without making the power cables thicker, since they are already very heavy and difficult to handle."

Using additives to protect the insulation plastic has been a known concept since the 1970s, but until now it has been unknown exactly what and how much to add.

Consequently, additives are currently not used at all for the purpose, and the insulation material is manufactured with the highest possible degree of chemical purity.

In recent years, other researchers have experimented with fullerenes in the electrically conductive parts of high-voltage cables. Until now, though, it has been unknown that the substance can be beneficial for the insulation material.

The Chalmers researchers have now demonstrated that fullerenes are the best voltage stabilizers identified for insulation plastic thus far. This means they have a hitherto unsurpassed ability to capture electrons and thus protect other molecules from being destroyed by the electrons.

To arrive at these findings, the researchers tested a number of molecules that are also used within organic solar cell research at Chalmers. The molecules were tested using several different methods, and were added to pieces of insulation plastic used for high-voltage cables. The pieces of plastic were then subjected to an increasing electric field until they crackled. Fullerenes turned out to be the type of additive that most effectively protects the insulation plastic.

The next step involves testing the method on a large scale in complete high-voltage cables for alternating current. The researchers will also test the method in high-voltage cables for direct current, since direct current is more efficient than alternating current for power transmission over very long distances.

The C60 carbon ball is also called buckminsterfullerene. It consists of 60 carbon atoms that are placed so that the molecule resembles a nanometer-sized football. C60 is included in the fullerene molecular class.

Fullerenes were discovered in 1985, which resulted in the Nobel Prize in Chemistry in 1996. They have unique electronic qualities and have been regarded as very promising material for several applications. Thus far, however, there have been few industrial usage areas.

Fullerenes are one of the five forms of pure carbon that exist. The other four are graphite, graphene/carbon nanotubes, diamond and amorphous carbon, for example soot.

If small amounts of fullerene are added to high-voltage cable insulation plastic, voltage can be increased by up to 26 per cent. This means the transmitted power also increases by up to 26 per cent, since the power = voltage multiplied by current. Energy loss in the form of heat, however, does not increase if the current is kept constant since heat losses primarily depend on current. Power transmission can thereby be increased by up to 26%, at the same time that energy loss stays at the same level – an efficiency increase in electric power transmission.

The research has been conducted by eight researchers at Chalmers University of Technology in Sweden, at the Department of Chemistry and Chemical Engineering and the Department of Materials and Manufacturing Technology, as well as a researcher at Borealis AB in Stenungsund, Sweden. Chalmers’ Areas of Advance Materials Science and Energy have been responsible for funding, as has Borealis AB.

For more information, read the scientific article, A New Application Area for Fullerenes: Voltage Stabilizers for Power Cable Insulation:

http://onlinelibrary.wiley.com/doi/10.1002/adma.201404306/full

About the Author

Sam Davis Blog

Editor-In-Chief - Power Electronics

Sam Davis was the editor-in-chief of Power Electronics Technology magazine and website that is now part of Electronic Design. He has 18 years experience in electronic engineering design and management, six years in public relations and 25 years as a trade press editor. He holds a BSEE from Case-Western Reserve University, and did graduate work at the same school and UCLA. Sam was the editor for PCIM, the predecessor to Power Electronics Technology, from 1984 to 2004. His engineering experience includes circuit and system design for Litton Systems, Bunker-Ramo, Rocketdyne, and Clevite Corporation.. Design tasks included analog circuits, display systems, power supplies, underwater ordnance systems, and test systems. He also served as a program manager for a Litton Systems Navy program.

Sam is the author of Computer Data Displays, a book published by Prentice-Hall in the U.S. and Japan in 1969. He is also a recipient of the Jesse Neal Award for trade press editorial excellence, and has one patent for naval ship construction that simplifies electronic system integration.