Body Heat Can Be the Source of Power for Wearable Devices

The article, Human Body Heat for Powering Wearable Devices: From Thermal Energy to Application, provides the information implied by its title. Authored by Moritz Thielen, Lukas Sigrist, Michele Magno, Christofer Hierold, and Luca Benini, it describes approaches for powering a wearable device, with details on the use of body heat as the source of power.

Another consideration in powering wearable devices is the necessity to impose weight and size constraints, particularly if you initially choose a battery as the source of power. To limit size and weight you should use energy harvesting instead of the battery. The article points out that you can harvest energy from several environmental sources:

- Light, using photovoltaics

- Movement of the wearer

- Radio frequency energy (RF)

- Temperature differences using a thermoelectric generator (TEG)

An evaluation of these environmental sources reveals that photovoltaic or RF harvesters limit the application of zero-power wearables to environments where sufficient ambient light or RF emissions is provided to satisfy the energy budget. Movement-based harvesting systems require an active wearer and usually have unstable power generation characteristics. In contrast, the human body is a constant heat source and typically a temperature difference exists between body core and the environment.

Even in a scenario where the wearer is stationary and situated in a dark room (e.g., during sleep), energy can be produced. Lower ambient temperatures, the presence of air convection, or increased activity of the wearer can drastically increase the amount of accumulated energy. Because the voltages produced by thermal harvesting are typically too low to power wearable electronics, you must include a high-efficiency dc-dc converter into a wearable system.

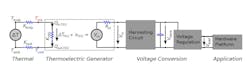

Figure 1 shows an equivalent circuit of the complete pathway from human body heat to a wearable hardware platform. Thermoelectric energy conversion of human body heat represents a promising alternative as it is largely independent of external factors. The average power harvested per square centimeter is higher using the thermal harvester than an equally sized solar cell. However, the produced voltage is used to directly charge a supercapacitor as an energy buffer and the device is only operational if the ambient temperature is lower than 25°C to 27°C. In one application a Thermoelectric Generator (TEG) on a human forehead powered a 2-channel EEG system with a power consumption of 0.8mW. You can harvest up to 30 μWcm-2 before dc-dc conversion (Voltage Regulation in Fig. 1). A two-stage custom dc-dc converter design is used to convert the voltage produced by the TEG to 2.75V. Due to the large thermal harvester, the system has limited wearability. Previous systems relied on custom designed and fabricated components, including the TEG and dc-dc circuits, to optimize the output power for a very specific application scenario. Application-specific components are necessary to obtain the power output and physical size required for a wearable sensor application. Plus, state-of-the-art thermal harvesters may be too bulky and uncomfortable to achieve true wearability.

1. Equivalent circuit of the pathway from human body heat to a wearable hardware platform.

Flexible TEG

North Carolina State University engineers came up with their own thermal harvester. In a proof-of-concept study, they designed a flexible thermoelectric energy harvester (Fig. 2) that has the potential to rival the effectiveness of existing power wearable electronic devices using body heat as the only source of energy.

Wearable devices have been used to monitor a variety of health and environmental measures and are now becoming increasingly popular. The performance and efficiency of flexible devices, however, pale in comparison to rigid devices, which have been superior in their ability to convert body heat into usable energy.

2. Liquid metal in the flexible thermoelectric device allows for self-healing. Rigid devices do not have the ability to heal themselves. (Photo courtesy of Mehmet Ozturk, North Carolina State University)

“We wanted to design a flexible thermoelectric harvester that does not compromise on the material quality of rigid devices yet provides similar or better efficiency,” says Mehmet Ozturk, a professor of electrical and computer engineering at NC State and corresponding author of a paper describing the work. “Using rigid devices is not the best option when you consider a number of different factors.” Ozturk mentioned superior contact resistance—or skin contact—with flexible devices, as well as the ergonomic and comfort considerations to the device wearer.

Ozturk said that he and colleagues Michael Dickey and Daryoosh Vashaee wanted to utilize the best thermoelectric materials used in rigid devices in a flexible package, so that manufacturers wouldn’t need to develop new materials when creating flexible devices.

Ozturk said one of the key challenges of a flexible harvester is to connect thermoelectric elements in series using reliable, low-resistivity interconnects. “We use a liquid metal of gallium and indium—a common, non-toxic alloy called EGaIn—to connect the thermoelectric ‘legs,’” Ozturk said. “The electric resistance of these connections is very low, which is critical since the generated power is inversely proportional to the resistance: Low resistance means more power.

“Using liquid metal also adds a self-healing function: If a connection is broken, the liquid metal will reconnect to make the device work efficiently again. Rigid devices are not able to heal themselves,” Ozturk added.

Ozturk said future work will focus on improving the efficiencies of these flexible devices, by using materials and techniques to further eliminate parasitic resistances.

Dickey, Vashaee, Francisco Suarez, Dishit P. Parekh, and Collin Ladd co-authored the paper, which appears in Applied Energy. The group also has a pending patent application on the technology.

Funding for the work comes from the NC State’s National Science Foundation-funded Advanced Self-Powered Systems of Integrated Sensors and Technologies (ASSIST) Center under grant (EEC1160483) and from other NSF support under grants ECCS1351533 and CMMI1363485. The ASSIST Center develops and employs nano-enabled energy harvesting, energy storage, nano devices and sensors to create innovative battery-free, body-powered, and wearable health monitoring systems.

About the Author

Sam Davis

Sam Davis was the editor-in-chief of Power Electronics Technology magazine and website that is now part of Electronic Design. He has 18 years experience in electronic engineering design and management, six years in public relations and 25 years as a trade press editor. He holds a BSEE from Case-Western Reserve University, and did graduate work at the same school and UCLA. Sam was the editor for PCIM, the predecessor to Power Electronics Technology, from 1984 to 2004. His engineering experience includes circuit and system design for Litton Systems, Bunker-Ramo, Rocketdyne, and Clevite Corporation.. Design tasks included analog circuits, display systems, power supplies, underwater ordnance systems, and test systems. He also served as a program manager for a Litton Systems Navy program.

Sam is the author of Computer Data Displays, a book published by Prentice-Hall in the U.S. and Japan in 1969. He is also a recipient of the Jesse Neal Award for trade press editorial excellence, and has one patent for naval ship construction that simplifies electronic system integration.

You can also check out his Power Electronics blog.