Stanford Researchers Pursue Ultrathin, Low-Power Semiconductors

Semiconductor R&D is a continuing process that looks for new, improved technologies and devices. This process follows along the same lines described by the American Chemical Society (ACS) for three main activities:

- Basic research ˗ projects that do not have a specific commercial objective, but evolve into applied research as they uncover new materials or solutions to problems.

- Applied research ˗ projects that aim to discover new knowledge related to a specific commercial objective.

- Development ˗ work that draws on existing research results and is directed specifically toward the creation of new and/or improved products and processes.

Basic research is where it all starts: new ideas, fundamental theories, unanswered questions, and investigation into something that doesn’t quite make sense. The basic researcher is driven by curiosity and a desire to explore unknown territory. Some ideas pan out, some don’t, and that is all part of the process. Basic research includes theoretical research, but it also includes early-stage investigations in the laboratory or field.

ACS figures indicate that in 2011, spending on basic research accounted for about 18% of all U.S. R&D activities. In the same year, the business sector performed 17% of the basic research, 57% of the applied research, and 88% of the development in the U.S.

Most basic research is done in academic laboratories, with government agencies and nonprofit organizations as major contributors. (The U.S. academic sector performed 15% of all research, but 55% of basic research in 2011.) More than half of all basic research funding comes from government sources.

Obviously, an engineer needs a strong theoretical background to work in basic research. However, all engineers are not cut out for basic research. As ACS points out, the exploratory nature of basic research requires a high tolerance for uncertainty, an ability to deal with ambiguity, and perseverance to continue after a setback. Coming up with new ideas requires curiosity and the ability to recognize interesting and unusual areas to pursue.

Basic research projects usually involve teams, according to the ACS. These can include a primary investigator and his or her students and postdocs; groups of researchers from one discipline; or researchers from several interrelated disciplines. Teams may involve researchers in many locations around the world, communicating by videoconference and sharing data using online collaboration tools. They may also enlist the help of computer scientists, other engineers, and instrument design specialists to help them develop the new capabilities they need.

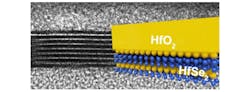

A good example of basic research is the current work done by Stanford University engineers. The researchers realized what chipmakers appreciate and most consumers never knew: silicon “rusts” in a way that insulates its tiny circuitry. The researchers identified two semiconductors—hafnium diselenide (HfSe2) (Fig. 1) and zirconium diselenide (ZrSe2)—that share or even exceed some of silicon’s desirable traits, starting with the fact that these materials can “rust.” The two diselenides even outdo silicon in other ways that make them promising materials for future semiconductors. Zirconium is commercially produced as a byproduct of titanium and tin mining; it is not found in nature as a free element. Hafnium resembles zirconium and is found in many zirconium minerals. Selenides are minerals that have the selenide anion as a main component.

“It’s a bit like rust, but a very desirable rust,” said Eric Pop, an associate professor of electrical engineering at Stanford, who co-authored with post-doctoral scholar Michal Mleczko a paper that appears in the journal Science Advances.

The next generation of feature-filled and energy-efficient electronics will require computer chips just a few atoms thick. For all its positive attributes, trusty silicon can’t take us to these ultrathin extremes.

To meet this future miniaturization need, the new materials can also be shrunk to functional circuits just three atoms thick, and they require less energy than silicon circuits. Although still experimental, the researchers said the materials could be a step toward the kinds of thinner, more energy-efficient chips demanded by systems of the future.

Silicon’s Strengths

Silicon has several qualities that have led it to become the bedrock of electronics, Pop explained. One is that it is blessed with a very good “native” insulator, silicon dioxide (or, in plain English, silicon rust). Exposing silicon to oxygen during manufacturing gives chipmakers an easy way to isolate their circuitry. Other semiconductors do not “rust” into good insulators when exposed to oxygen, so they must be layered with additional insulators, a step that introduces engineering challenges. The diselenides tested by the Stanford group formed this elusive, yet high-quality insulating rust layer when exposed to oxygen.

Not only do both ultrathin semiconductors rust, they do so in a way that is even more desirable than silicon. They form what are called “high-K” insulators, which enable lower power operation than what is possible with silicon and its silicon oxide insulator.

As the Stanford researchers started shrinking the diselenides to atomic thinness, they realized that these ultrathin semiconductors share another of silicon’s secret advantages: the energy needed to switch transistors on—a critical step in computing, called the band gap—is in a just-right range. Too low and the circuits leak and become unreliable. Too high and the chip takes too much energy to operate the same optimal range as silicon.

All this and the diselenides can also be fashioned into circuits just three atoms thick, or about two-thirds of a nanometer, something silicon cannot do.

“Engineers have been unable to make silicon transistors thinner than about five nanometers, before the material properties begin to change in undesirable ways,” Pop said.

The combination of thinner circuits and desirable high-K insulation means that these ultrathin semiconductors could be made into transistors 10 times smaller than anything possible with silicon today.

“Silicon won’t go away. But for consumers this could mean much longer battery life and much more complex functionality if these semiconductors can be integrated with silicon,” Pop said.

More Work to Do

There is much work ahead. First, Mleczko and Pop must refine the electrical contacts between transistors on their ultrathin diselenide circuits. “These connections have always proved a challenge for any new semiconductor, and the difficulty becomes greater as we shrink circuits to the atomic scale,” Mleczko said.

They are also working to better control the oxidized insulators to ensure they remain as thin and stable as possible. Last, but not least, only when these things are in order will they begin to integrate with other materials and then to scale up to working wafers, complex circuits and, eventually, complete systems.

“There’s more research to do, but a new path to thinner, smaller circuits—and more energy-efficient electronics—is within reach,” Pop said.

These diselenides could provide transistors that are 10 times smaller than the 5nm chips you get from silicon alone. However, much additional work must be done to make these semiconductors into a full-size, production-worthy chip.

Additional Stanford contributors to this research include Chaofan Zhang, Hye Ryoung Lee, Hsueh-Hui Kuo, Blanka Magyari-Köpe, Robert G. Moore, Zhi-Xun Shen, Ian R. Fisher, and Professor Yoshio Nishi.

The work was supported by the Air Force Office of Scientific Research (AFOSR), the National Science Foundation, Stanford Initiative for Novel Materials and Processes (INMP), the Department of Energy (DOE) Office of Basic Energy Sciences, Division of Material Sciences, and an NSERC PGS-D fellowship.

About the Author

Sam Davis

Sam Davis was the editor-in-chief of Power Electronics Technology magazine and website that is now part of Electronic Design. He has 18 years experience in electronic engineering design and management, six years in public relations and 25 years as a trade press editor. He holds a BSEE from Case-Western Reserve University, and did graduate work at the same school and UCLA. Sam was the editor for PCIM, the predecessor to Power Electronics Technology, from 1984 to 2004. His engineering experience includes circuit and system design for Litton Systems, Bunker-Ramo, Rocketdyne, and Clevite Corporation.. Design tasks included analog circuits, display systems, power supplies, underwater ordnance systems, and test systems. He also served as a program manager for a Litton Systems Navy program.

Sam is the author of Computer Data Displays, a book published by Prentice-Hall in the U.S. and Japan in 1969. He is also a recipient of the Jesse Neal Award for trade press editorial excellence, and has one patent for naval ship construction that simplifies electronic system integration.

You can also check out his Power Electronics blog.