Supercap, Harvester May Let You Power Your Own Pacemaker

The problem with pacemakers and other implantable medical devices is providing long-term power. Even with their amazingly minuscule power needs and a run time measured in years, eventually there’s a need for surgery to replace the batteries. Considering that about 2.9 million patients received some sort of pacemaker between 1993 and 2009, that’s a lot of potential surgery.

1. The supercapacitor developed by researchers from UCLA and the University of Connecticut could lead to pacemakers and other implantable medical devices that last a lifetime. (Photo courtesy of Islam Mosa/University of Connecticut and Maher El-Kady/UCLA)

But this situation may change due to advances in self-powered devices using a human-compatible supercapacitor developed by a joint team of researchers at the University of California at Los Angeles (UCLA) and the University of Connecticut (Fig. 1). This energy-storage component uses electrolytes found in biological fluids such as blood serum and urine to charge. It works with an internal energy harvester that converts heat and motion of the body into electricity. The supercapacitor captures that trickle of energy and delivers it as needed to power to the implanted device.

Conventional pacemakers are 6 to 8 mm thick with a diameter of about 30 mm, with the battery being about half of the device volume. The new supercapacitor is about 1 mm thick and can also bend and twist in the body without being damaged (Fig. 2)—an important consideration—and can store more charge than the lithium-film batteries used in regular pacemakers.

The biosupercapacitor is made of graphene layered with modified human proteins that act as an electrode for electricity storage and delivery. “In order to be effective, battery-free pacemakers must have supercapacitors that can capture, store and transport energy, and commercial supercapacitors are too slow to make it work,” said Maher El-Kady, a UCLA postdoctoral researcher and one of the co-authors of the study. “Our research focused on custom-designing our supercapacitor to capture energy effectively, and finding a way to make it compatible with the human body.”

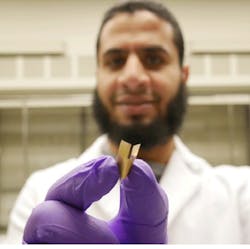

2. Chemistry Ph.D. student Islam Mosa holds an ultrathin implantable bioelectronic device that he developed. It’s powered by a novel supercapacitor capable of generating enough power to sustain a cardiac pacemaker. The device is more biocompatible and lasts much longer than existing pacemaker batteries. (Photo courtesy of Islam Mosa)

The device has also been shown to be non-toxic to living cells. “We charged and discharged the device in a petri dish to see what happened to cell cultures, and surprisingly it had no effect at all,” added Ph.D. student Islam Mosa of the University of Connecticut. “Because the supercapacitor components are compatible with the biological environment, even if it leaks, it would have no detrimental effect on the patient.”

The work is described in detail in the 12-page paper “Ultrathin Graphene–Protein Supercapacitors for Miniaturized Bioelectronics”, which includes eleven authors, detailed analysis and graphs, and numerous references, and is published online in the journal Advanced Energy Materials. The National Institute of Health’s National Institute of Biomedical Imaging and Bioengineering, the National Institute of Health’s National Institute of Environmental Health Sciences, and a National Science Foundation EAGER grant funded the research.

About the Author

Bill Schweber

Contributing Editor

Bill Schweber is an electronics engineer who has written three textbooks on electronic communications systems, as well as hundreds of technical articles, opinion columns, and product features. In past roles, he worked as a technical website manager for multiple topic-specific sites for EE Times, as well as both the Executive Editor and Analog Editor at EDN.

At Analog Devices Inc., Bill was in marketing communications (public relations). As a result, he has been on both sides of the technical PR function, presenting company products, stories, and messages to the media and also as the recipient of these.

Prior to the MarCom role at Analog, Bill was associate editor of their respected technical journal and worked in their product marketing and applications engineering groups. Before those roles, he was at Instron Corp., doing hands-on analog- and power-circuit design and systems integration for materials-testing machine controls.

Bill has an MSEE (Univ. of Mass) and BSEE (Columbia Univ.), is a Registered Professional Engineer, and holds an Advanced Class amateur radio license. He has also planned, written, and presented online courses on a variety of engineering topics, including MOSFET basics, ADC selection, and driving LEDs.