Metamaterials Boost MRI Performance without Increased Magnetic Field

Improving the resolution, signal-to-noise ratio (SNR), and other performance attributes of magnetic-resonance-imaging (MRI) systems generally requires stronger magnetic fields in addition to other improvements. Present medical MRIs have magnetic-field strengths from as low as 1.5 tesla (T) up to 7 T, and some have even higher-strength fields. However, increasing field strength is a costly, bulky, complex step-up in the machine’s design, construction, installation, power demands, operation, and maintenance.

Now, a team at the Boston University Photonics Center has devised a way to boost MRI performance without resorting to these stronger magnetic fields. They use a magnetic metamaterial made of helical resonators, which are 3-cm-tall structures created from 3D-printed plastic, and coils of thin copper wire (Fig. 1). These resonators are then grouped in an array that’s flexible enough to cover the body part being imaged and interact with the magnetic field of the machine, resulting in an increase in effective SNR. Alternatively, it can also allow use of lower-strength MRI machines, providing comparable performance or faster scan times.

This isn’t the first use of some sort field-shaping adjunct to boost performance. Various resonator arrays have been explored as well as magneto-inductive waveguides. However, these have had detrimental issues related to magnetic-field inhomogeneity and the potential for generating strong electric fields, raising potential safety concerns

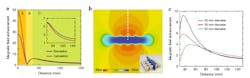

The primary figure of merit is the magnetic-field enhancement ratio of the metamaterials, which is a function of many variables including resonator diameter, spacing, and placement. The array of metallic helical unit cells yields collective resonant modes to interact with the magnetic field in MRI. The team performed many EM-field simulations across these variables, among them the ones shown in Figure 2.

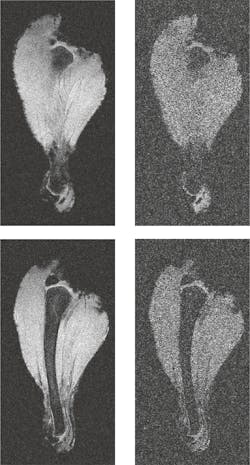

Beyond simulation, they tested their approach by scanning chicken legs, tomatoes, and grapes using a 1.5 T machine (Fig. 3). Results showed the magnetic metamaterial yielded a 4.2X increase in the SNR.

Project leaders Xin Zhang, professor of mechanical engineering, electrical and computer engineering, biomedical engineering, and materials science and engineering at the College of Engineering and a BU Photonics Center faculty member, along with Stephan Anderson, School of Medicine professor of radiology, vice chairman of research in Boston Medical Center’s radiology department, and a Photonics Center faculty member) hope to partner with industry collaborators so that their magnetic metamaterial can be adapted for real-world clinical applications as well as applications in non-clinical settings.

“If you are able to deliver something that can increase SNR by a significant margin, we can start to think about possibilities that didn’t exist before,” says Anderson. This could include having MRI near battlefields or in other remote locations. “Being able to simplify this advanced technology is very appealing.”

All aspects of the project are described in elaborate detail in their paper “Boosting magnetic resonance imaging signal-to-noise ratio using magnetic metamaterials” along with its Supplementary Information, which includes extensive EM-field and other analyses, published in Nature’s Communications Physics. The work was supported by the National Institutes of Health, the Boston University College of Engineering Dean’s Catalyst Award, the Boston University Wallace H. Coulter Translational Research Partnership Award, and the Boston University Ignition Award.

About the Author

Bill Schweber

Contributing Editor

Bill Schweber is an electronics engineer who has written three textbooks on electronic communications systems, as well as hundreds of technical articles, opinion columns, and product features. In past roles, he worked as a technical website manager for multiple topic-specific sites for EE Times, as well as both the Executive Editor and Analog Editor at EDN.

At Analog Devices Inc., Bill was in marketing communications (public relations). As a result, he has been on both sides of the technical PR function, presenting company products, stories, and messages to the media and also as the recipient of these.

Prior to the MarCom role at Analog, Bill was associate editor of their respected technical journal and worked in their product marketing and applications engineering groups. Before those roles, he was at Instron Corp., doing hands-on analog- and power-circuit design and systems integration for materials-testing machine controls.

Bill has an MSEE (Univ. of Mass) and BSEE (Columbia Univ.), is a Registered Professional Engineer, and holds an Advanced Class amateur radio license. He has also planned, written, and presented online courses on a variety of engineering topics, including MOSFET basics, ADC selection, and driving LEDs.