Design Platform Brings Sensorless Control to Energy Efficient Washers

International Rectifier (IR) has introduced a sensorless control platform for direct-drive permanent magnet (PM) synchronous motor washing machines. The iMOTION Integrated Design Platform For Washers provides the hardware, software, and design tools required to control the PM synchronous motors used in new washing machine designs. These motors are gaining popularity in part because they offer greater efficiency and smaller size than the belt driven induction motors they replace. Moreover, the PM synchronous motors support the transition from top loading washing machines to the more energy-efficient front loading machines.

However, unlike induction motors which employ tachometers for speed control, the PM synchronous motors typically require Hall Effect sensors to determine rotor position. Although these sensors are relatively inexpensive, they cause failures in the field. With the new iMOTION platform, washing machine designers can eliminate these sensors using a control chip that senses current in the dc link and then uses that information to calculate the back EMF of the motor windings.

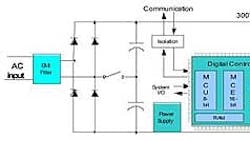

The Integrated Design Platform For Washers features a mixed-signal controller and companion intelligent power modules as well as algorithms, development software, and design tools (Fig 1). Combined in one platform, iMOTION for washers simplifies design of variable-speed motor-control in both horizontal (front loading) and vertical axis (top loading) washing machines, accelerating time-to-market and reducing overall system cost.

“The application of direct-drive PMS motors in washing machines improves system dynamics and reduces overall system cost due to a simpler mechanical structure. Typically, Hall Effect sensors are deployed to provide rotor position information necessary for control of these motors, adding cost and complexity to the motor design. The iMOTION platform enables sensorless sinusoidal current control, completely eliminating Hall Effect sensors and delivering smooth torque over an extended speed range. The bottom line is that the iMOTION approach should accelerate deployment of energy-efficient motors, helping us to save a great deal of electricity,” said David Tam, vice president of International Rectifier’s Energy -Saving Products Segment.

The high-performance IRMCF341 washer control IC integrates all the control and analog interface functions required for sensorless speed control of PMS motors using dc link current measurements (Fig 2). The analog functions on the IC include differential amplifier, dual sample and hold circuits and a 12-bit A-D converter to sample the low-voltage signal across the dc link shunt.

The control IC features IR’s Motion Control Engine (MCE) that eliminates software coding from the motion control algorithm development process. A cointegrated 60-MIPS, 8-bit, 8051 microcontroller enables application layer software development, operating almost independently of the MCE and does not compete for system resources such as interrupts or internal registers. This streamlines application software debugging since the MCE can be treated very much like a hardware peripheral with a set of input and output registers.

The embedded Analog Signal Engine (ASE) integrates all the signal conditioning and conversion circuits required for single current shunt, sensorless control of a PMS motor. The IRMCF341 control IC is available in a 64-pin QFP package with all the required analog inputs and PWM outputs to control the washing machine motor.

The companion IRAMS06UP60B and IRAMS10UP60B inverter power modules feature an advanced high-voltage gate drive IC for three-phase inverter control. The modules include the dc link shunt used for both motor current measurement and power module protection. Built-in overtemperature and overcurrent protection, along with short-circuit rated IGBTs, an integrated undervoltage lockout function, and temperature monitor provide a high level of protection and fail-safe operation.

The platform includes the IRMCS3041 reference design, in addition to web-based software tools, to customize application requirements. The embedded (Field Oriented Control) FOC algorithm optimizes the output torque from interior permanent magnet motors and maximizes bus voltage utilization in the high-speed field weakening mode.

Tools include communications software running on the 8051 microcontroller that gives the PC-based MCEDesigner software access to the control parameters and system variables in the shared memory. This allows modification of the controller set points and control loop gains and other constants without needing to modify or compile software. MCEDesigner tools generate wash-cycle profiles and plot motor speed and current, accelerating rapid evaluation of direct-drive motor performance with real washing loads.

Data sheets and application notes are available on the International Rectifier Web site, www.irf.com. The iMOTION washer platform is being sampled to qualified users. The IRMCS3041 reference design is $995 in single unit quantities. Contact your local IR sales representative or the IR Technical Assistance Center at http:tac.irf.com for more details.