Power Controller Merges, Manages Multiple Large-Scale Energy Sources

There’s a management-and-control problem when multiple power sources—solar, diesel generator, and batteries—each has variable, non-static availability. Deciding which one(s) to use and to what extent must be done properly for maximum efficiency and performance, of course. It’s possible to manually switch among them, but that’s awkward, carries risk of misconnection, and is inefficient.

Engineers at the Energy Department's National Renewable Energy Laboratory (NREL), in conjunction with KBR (El Segundo, Calif., formerly Wyle Laboratories), worked to solve just such a problem for the U.S. Army’s field installations. Transporting conventional fuel is costly and risky, especially to forward operating bases associated with hostilities and combat zones, so the Army wants to reduce reliance on these fuels to the best extent possible.

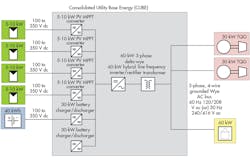

1. The Consolidated Utility Base Energy (CUBE) can mix and merge power supplied by solar, diesel-generator, and battery sources, functioning as a microgrid up to 60 kW. (Source: National Renewable Energy Laboratory)

That’s where NREL’s Consolidated Utility Base Energy—CUBE—could play a major role (Fig. 1). The unit, which measures about three feet wide, six feet long, and five feet tall, converts power from different sources (solar panels, batteries, and generators) into usable electricity, functioning as a microgrid. It quickly and autonomously switches among the different sources to deliver uninterrupted power.

Though the CUBE doesn’t store energy, instead the unit manages its sourcing and flow, it has the potential to cut diesel fuel use by as much as 25% on average. In a series of demonstration tests using two diesel generators, a lithium-ion battery, and simulated solar panels, the CUBE achieved up to 31% savings in fuel use compared to the diesel generators operating alone.

NREL’s team designed the control platform that allows the CUBE to operate across a large number of combination-source modes, and to transition smoothly from one mode to another. The hybrid power system integrates four 5- to 10-kW photovoltaic (PV) arrays, one 30-kW battery pack, and two 30-kW diesel generator sets to support a 60-kW peak load (Fig. 2). The onboard power electronics include PV maximum power point tracking (MPPT) converters, battery charge/discharge converters, and a three-phase inverter delivering 120/240 V ac. It operates as the grid-forming unit and operates in parallel with the diesel generators. The unit is installed on a standard 15-kW Tactical Quiet Generator (TQG) skid.

2. Gregory Martin and Mariko Shirazi of NREL examine the CUBE. Its 60-kW rating mandates a number of fairly substantial cabling and connectors. (Source: National Renewable Energy Laboratory)

The CUBE provides three key functions: power conversion, power distribution, and power protection (extremely critical in field installations) (Fig. 3). The hierarchal CUBE control architecture has three software-driven functional levels (local control, mode handling, and component dispatch), and two hardware levels (a local controller for each power-electronic interface, and a supervisory controller). The software manages the critical tasks of load assessment, source availability, and controls system operation, including functions such as measuring flow of diesel fuel.

3. The high-level block diagram of the CUBE system shows its basic power input and output connections and some of the internal complexity; not shown is its extensive power-protection features. (Source: National Renewable Energy Laboratory)

Nearly all of the hardware is standard, off-the-shelf components and modules. The control platform is based on National Instruments’ CompactRIO modules, each of which includes an FPGA backplane and a real-time processor, while the power-electronic converters use Semikron SKAI modules. These modules include insulated-gate bipolar transistor (IGBT) power semiconductors; dc link capacitors; gate drivers with low-level protection; and voltage, current, and temperature sensors.

The first CUBE is designed to meet military specifications, including from −40°C (-40°F) up to 60°C (+140°F), and features a liquid-cooled system similar to a truck's radiator. However, the research team stresses that this is a lab demonstration/evaluation unit, and not ready for production or deployment. NREL electrical engineer Mariko Shirazi says, ”…if you look at it, there are wires all over the place…It's a maintenance nightmare. If anybody ever wanted to replace something, you've got to take the whole thing apart to get at it. From a mechanical integration point of view, it would need to be designed by somebody with manufacturing expertise."

Applications for CUBE go beyond military situations. It could be used in other remote locations, or even provide emergency power management after natural disasters. The NREL team has posted a 68-page, detailed report on the objectives, design, and evaluation of their CUBE prototype, “Consolidated Utility Base Energy (CUBE) Performance Test Report.” It includes not only high-level discussion, but block diagrams, schematics, list of vendor/models of all internal units and test equipment, test setup, and results.

About the Author

Bill Schweber

Contributing Editor

Bill Schweber is an electronics engineer who has written three textbooks on electronic communications systems, as well as hundreds of technical articles, opinion columns, and product features. In past roles, he worked as a technical website manager for multiple topic-specific sites for EE Times, as well as both the Executive Editor and Analog Editor at EDN.

At Analog Devices Inc., Bill was in marketing communications (public relations). As a result, he has been on both sides of the technical PR function, presenting company products, stories, and messages to the media and also as the recipient of these.

Prior to the MarCom role at Analog, Bill was associate editor of their respected technical journal and worked in their product marketing and applications engineering groups. Before those roles, he was at Instron Corp., doing hands-on analog- and power-circuit design and systems integration for materials-testing machine controls.

Bill has an MSEE (Univ. of Mass) and BSEE (Columbia Univ.), is a Registered Professional Engineer, and holds an Advanced Class amateur radio license. He has also planned, written, and presented online courses on a variety of engineering topics, including MOSFET basics, ADC selection, and driving LEDs.