Wind is blowing solar away in the United States when it comes to renewable power generation, according to recent reports from Department of Energy (DoE) laboratories. For example, newly built large-scale wind projects can offer energy at prices averaging around 2¢/kWh, and smaller, distributed wind projects located near the points of energy consumption produced energy at estimated average costs of 11¢/kWh in 2015.

The first report comes from Lawrence Berkeley National Laboratory (Berkeley Lab), whose authors state, “Annual wind-power capacity additions in the United States surged in 2015 and are projected to continue at a rapid clip in the coming five years. Recent and projected near-term growth is supported by the industry’s primary federal incentive—the production tax credit—as well as a myriad of state-level policies.”1

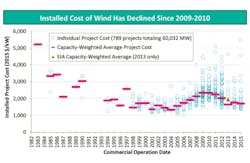

They note that with 8,598 MW of new capacity (with average nameplate turbine ratings of 2 MW), wind power at 41% represented the largest source of all added capacity in the United States in 2015. They report that installed project costs have fallen over time except for an increase due to turbine price changes centered around 2009-2010 (see graph).

Courtesy of Berkeley Lab

They add that wind prices are very low, with power-purchase agreement prices (for example, the price a utility pays to a wind-farm operator) falling from $70/MWh in 2009 to $20/MWh in 2015.

In addition, the DoE’s Pacific Northwest National Laboratory (PNNL) focused on distributed wind, issuing a report noting that U.S. companies are increasingly making their own power with wind turbines located near their factories.

“Wind plays a key role in the rising area of distributed energy,” said report co-author Alice Orrell, an energy analyst at PNNL.2

“Although distributed wind is not as widespread as distributed solar, new third-party financing options similar to the lease model that spurred growth in the residential solar market also could grow distributed wind,” added PNNL energy analyst Nik Foster, the other

co-author.

Here are some key findings from the PNNL report:

- Industrial uses accounted for 37% of the distributed wind capacity added in 2015.

- Exports of small wind turbines (up to 100 kW) doubled from 2014 to 2015, with Italy, the United Kingdom, and Japan among the largest importers.

- The estimated cost of energy produced by small distributed wind turbines was 11¢/kWh in 2015.

In related news, in May Whirlpool announced plans to build wind turbines to help power its Marion and Ottawa plants in Ohio, a $13.5 million total investment. The company said the completion of these projects has the potential to make it one of the largest Fortune 500 consumers of onsite wind energy in the United States.

The three Marion turbines—scheduled for completion in early 2017—are expected to offset Whirlpool’s electric consumption by 19%. Ottawa’s turbine is projected to offset the plant’s electrical consumption by 34% once completed at the end of 2016.

Whirlpool said it also will create one $5,000 STEM scholarship per wind turbine to be awarded annually to a graduating senior from local Marion and Ottawa high schools.

Further improvements in wind generation could come in the form of increased use of carbon fiber to make turbine blades lighter and stronger. To that end, Tour de France champion Greg LeMond is teaming up with Oak Ridge National Laboratory (ORNL) to manufacture low-cost carbon fiber at high volume.

“We can provide the advantages of our carbon fiber to many industries by improving strength, stiffness, and weight reduction,” said Connie Jackson, CEO of the newly formed LeMond Composites. Under a licensing agreement, the company will employ a process developed by Jackson and a research team at ORNL that could cut production costs 50% relative to today’s lowest cost industrial-grade carbon fiber. Jackson and several ORNL teammates joined LeMond Composites earlier this year.

In addition to wind power, LeMond Composites intends to address automotive, shipping, air-travel, and marine industries, and the composites could be used to build, reinforce, or repair bridges, tunnels, and commercial and residential structures.

The company expects to offer commercially available products in the first quarter of 2018.

References

- Wiser, R. and Bolinger, M., 2015 Wind Technologies Market Report, U.S. Department of Energy, August 2016.

- “Local wind powering more U.S. companies,” Newswise, Aug. 17, 2016.

About the Author

Rick Nelson

Contributing Editor

Rick is currently Contributing Technical Editor. He was Executive Editor for EE in 2011-2018. Previously he served on several publications, including EDN and Vision Systems Design, and has received awards for signed editorials from the American Society of Business Publication Editors. He began as a design engineer at General Electric and Litton Industries and earned a BSEE degree from Penn State.