Designing Smart, Bidirectional Onboard Chargers for V2X-Enabled EVs

Members can download this article in PDF format.

What you'll learn:

- The ABCs of OBCs.

- Benefits of bidirectional OBCs.

- Issues and solutions to implementing 2D-OBCs.

Thanks to their large storage batteries, with capacities measured in the tens of kWh, electric vehicles (EVs) can provide many other purposes besides transportation. A few vehicles presently on the market, such as later-model Nissan Leaf EVs, have vehicle-to-grid (V2G) capabilities that enable it to sell its power back to the grid during periods when generating capacity exceeds demand.

Others, such as Ford's F-150 Lightning pickup truck, offer vehicle-to-load (V2L) capabilities, with 110-V ac outlets capable of powering appliances, electronics, or even circular saws and other power tools at remote job sites.1 Several manufacturers also offer, or are considering offering, vehicle-to-vehicle (V2V) capabilities that enable an EV to directly charge another vehicle.

While all of these capabilities (collectively referred to as vehicle-to-everything, or V2X) are very desirable, their widespread adoption hinges on the development of cost-effective onboard chargers (OBCs) that can both charge their vehicle's batteries and, when needed, make their stored energy available for other applications. But the adoption of bidirectional OBCs (2D-OBCs) has been slowed by the challenges involved with implementing these capabilities in an energy-efficient or cost-effective manner.

In this overview, we’ll look at some of the requirements 2D-OBCs must meet, and some of the new technologies and design techniques being used to implement practical V2X solutions.

Intro to OBCs

OBCs allow EVs to be charged directly from relatively simple charging stations that supply ac or, in some cases, dc from the grid. OBCs work with two of the three classes of chargers:

- Level 1 chargers supply power from a single-phase 120/230-V ac line and can provide a maximum charging power of roughly 7kW.

- Level 2 chargers draw their power from a three-phase 208/230-V ac line and can charge the EV's batteries at typical rates of up to 22 kW, and, in some cases, as high as 44 kW.

- Level 3 chargers, also known as dc fast chargers (DCFCs) or superchargers, can charge batteries with dc voltages of up to 600 V at rates of up to 400 A. To do this, they bypass the OBC to feed the battery directly. Thus, they won't be discussed in this article.

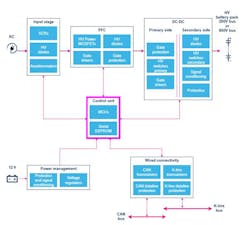

At present, most EVs use two-stage OBCs that consist of an ac-dc converter, which also includes a power-factor-correction (PFC) function, and an isolated dc-dc converter (Fig. 1).

The ac-dc + PFC converter supplies a controllable dc voltage and limits the amount harmonic/phase noise it puts back onto the grid. The isolated dc-dc converter stage provides galvanic isolation and regulates the power delivered to the battery according to its present level of charge, temperature, and other factors. Isolation is usually accomplished using a dc-link capacitor that provides energy buffering and filtering against voltage spikes, surges, and EMI.

Bidirectional OBCs

Once they enter mainstream production, 2D-OBCs should only add a small amount to an EV's sticker price, but they add significantly to the value they offer to their owners. For example, EVs equipped with V2H capabilities could give consumers a very cost-effective alternative to so-called "power walls" used to provide electricity to solar-powered homes when the sun isn’t shining. A typical EV has a battery capacity of 60 kWh, roughly 6X larger than a typical home battery bank (10 kWh, cost: $8K-$12K), and around 3X more energy than an average household consumes in a day.

Consumers also stand to benefit from an EV's V2G capabilities, regardless of whether they have solar, by selling access to a specified percentage of their battery's capacity to their electric utility. At its simplest, the utility would pay EV owners to use thousands of vehicles distributed across the grid to help meet peak load demands that exceed their generating capacity.

In addition, EVs equipped with 2D-OBCs could also generate revenue for their owners by serving as distributed regulation nodes. In this mode, the EV's PFC and filtering electronics would provide frequency and voltage regulation, which balances the supply and demand for active power and reactive power, as well as help reduce grid current harmonics.2

The functional requirements for these, and other V2G functions, are defined by the standard ISO 15118:2 that includes ac and dc bidirectional charging, and smart functions for payments both to and from the energy supplier. It also involves the standards that define communication between an EV and a bidirectional charger.3

Implementation Issues

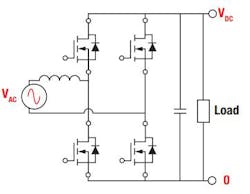

So-called totem-pole topologies are becoming increasingly popular for implementing the PFC element of 2D-OBCs. In addition to their ability to support bidirectional operation, they have a small common-mode (CM) current and input current ripple, and their simplified architecture typically requires fewer components while enabling higher power density and efficiency.4

Until recently, though, it wasn’t practical to implement high-power totem-pole PFCs because of the limitations of silicon power devices, which made them impractical for multi-kilowatt applications (Fig. 2). This has changed thanks to the widespread availability of MOSFETs and diodes fabricated in gallium nitride (GaN) or silicon carbide (SiC), also known as wide-bandgap (WBG) semiconductors.

WBG devices exhibit significantly lower reverse-recovery charge and internal capacitances, enabling higher switching speeds. They’re also more efficient, typically cutting losses by 80% to 90%, as compared to comparably rated silicon MOSFETs.

GaN/SiC FET devices' lower losses and higher operating frequencies can improve the converter's efficiency while reducing the size of their magnetic components. As a result, they can support the hard-switching operation used by continuous-conduction-mode (CCM) totem-pole PFCs. By limiting the switching frequency to around 100 kHz, it’s possible to achieve 98% to 99% efficiency with a GaN- or SiC-based design.5

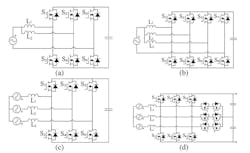

Furthermore, WBG devices are improving the performance of the secondary-side rectification function. While unidirectional OBCs can use relatively simple passive or active solutions, a bidirectional OBC's secondary rectification will need to be based on a full bridge that supports CLLC/CLLLC operation, or the second half of a dual active bridge.

In these applications, WBG devices' high efficiency and tolerance for elevated operating temperatures improves reliability and simplifies cooling requirements. Figure 3 illustrates several of the most common topologies for bidirectional dc-dc converters used in OBCs.

Analog Advances Drive Digital Innovation

2D-OBCs are being made possible by advanced power semiconductors. However, their higher operating speeds and more complex topologies employed also place higher demands on the microcontrollers (MCUs) used to manage their switching, regulation, and protection functions.

For example, an interleaved totem-pole critical-conduction-mode (CRM) PFC controller requires an MCU capable of supporting high-frequency, high-resolution pulse-width-modulation (PWM) synthesis to control the converter’s duty cycle, frequency, deadband, and phase-shift. Even with a relatively fast processor core, the MCU will still need math accelerators to accomplish the necessary calculations in real-time. It will also require analog integration to reduce the number of external components in the design, such as comparators and digital-to-analog converters (DACs).

In addition, the PWM switching frequency will vary according to load and operating conditions. For reliable operation, the MCU must be able to smoothly produce PWM waveforms that continuously vary in frequency without any generating glitches or other irregular behavior that could induce system or component damage to cause the converter to fail.

Looking Forward

As advanced power devices and MCUs help make V2X capabilities more commonly available, EVs will begin to play an expanded role in creating a vibrant, sustainable low-carbon economy. Their 2D-OBCs will enable the vehicle’s batteries to be used to augment the grid's storage capacity while producing revenue for their owners. They will also provide EV owners with a low-cost source of backup power for their homes or small businesses.

References

1. “What’s Bidirectional Charging and Which EVs Offer It?,” Jane Ulitskaya, Cars.com, September, September 28, 2022.

2. “A Review of Bidirectional On-Board Chargers for Electric Vehicles,” Jiaqi Yuan, Lea Dorn-Gomba, Alan Dorneles Callegaro, John Reimers, and Ali Emadi, IEEE Explore, April 2021.

3. “Vehicle-to-grid charging - E-Mobility Engineering,” emobility-engineering.com.

4. “A comparative analysis of topologies for a bridgeless-boost PFC circuit,” Salil Chellappan, Texas Instruments Design Journal, 2018.

5. “Meeting the demand for more efficient and powerful onboard chargers,” Sang Chon, Texas Instruments, 2019.

About the Author

Lee Goldberg

Contributing Editor

Lee Goldberg is a self-identified “Recovering Engineer,” Maker/Hacker, Green-Tech Maven, Aviator, Gadfly, and Geek Dad. He spent the first 18 years of his career helping design microprocessors, embedded systems, renewable energy applications, and the occasional interplanetary spacecraft. After trading his ‘scope and soldering iron for a keyboard and a second career as a tech journalist, he’s spent the next two decades at several print and online engineering publications.

Lee’s current focus is power electronics, especially the technologies involved with energy efficiency, energy management, and renewable energy. This dovetails with his coverage of sustainable technologies and various environmental and social issues within the engineering community that he began in 1996. Lee also covers 3D printers, open-source hardware, and other Maker/Hacker technologies.

Lee holds a BSEE in Electrical Engineering from Thomas Edison College, and participated in a colloquium on technology, society, and the environment at Goddard College’s Institute for Social Ecology. His book, “Green Electronics/Green Bottom Line - A Commonsense Guide To Environmentally Responsible Engineering and Management,” was published by Newnes Press.

Lee, his wife Catherine, and his daughter Anwyn currently reside in the outskirts of Princeton N.J., where they masquerade as a typical suburban family.

Lee also writes the regular PowerBites series.