DC Regeneration When Testing or Forming Li-Ion Cells

What you'll learn:

- How does regeneration work?

- The positives and negatives of ac regeneration.

- The benefits of dc regeneration.

In October 2021, I presented an article called “Reap the Benefits of Regeneration when Testing or Forming Li-Ion Cells.” It explained that cell testing and cell formation is happening on an increasing scale thanks to the adoption of electric vehicles. Every cell or battery manufactured or tested will consume ac power as an unavoidable cost of the charging operation. On the other hand, discharging pulls stored energy out of the cells/batteries.

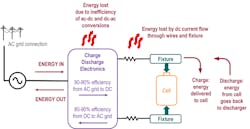

Without regeneration, energy is converted to heat and the energy is wasted, but that’s not a green approach (Fig. 1). Going green means employing systems that provide regeneration, which is a highly sought-after method to recoup that energy, converting it back to ac power and reusing the ac power to drive other devices connected to the same ac line. If there’s an abundance of regenerated power, the excess can flow back onto the grid.

AC Regeneration with AC Power Distribution

As shown in Figure 2, cell-formation systems or high-power battery test systems take the energy from discharging cells/batteries, convert it to ac, and return the ac power back to the ac line. Once the power returns to the ac line, the ac power distribution wiring within the facility carries this ac power, along with power from the grid to other equipment consuming ac power.

The ac-power-consuming equipment could be industrial systems, like other cell formation or battery testers that are consuming power to charge cells or batteries. Other ac-power-consuming equipment range from industrial machinery, facility lighting, and air conditioning to office equipment, IT infrastructure, or anything that’s plugged in and running on ac power.

The advantage of ac distribution is the distribution wiring already exists within the facility. Furthermore, any ac-powered device plugged into the ac line is a suitable user of such power available on the ac distribution wiring network. The national electrical code governs how to construct the ac distribution system wiring, and ac voltage standards govern the ac voltages, ac frequencies, line impedances, and safety regulations for how ac-powered devices operate when connected to the ac distribution network.

However, to achieve ac distribution, the regenerative system must have a dc-to-ac inverter to put power back on the ac line. This power stage experiences some losses.

While dc-to-ac inverters can have efficiencies of around 96%, this still represents losses that may add up to considerable wasted power when high-power forming or testing systems are operating. Similarly, when utilizing power from the ac line, these systems must have an ac-to-dc power stage, which also has similar inefficiencies and creates losses when consuming the ac power to charge the cells/batteries.

DC Regeneration with DC Power Distribution

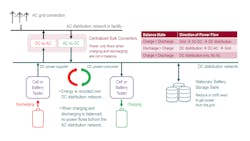

With dc regeneration and distribution, this final dc-to-ac power stage is removed from each regenerative system (Fig. 3). Without this dc-to-ac power stage, instead of ac power flowing back to the ac line, dc power is placed on a custom-built dc distribution network. The dc power is then made available to other compatible equipment consuming dc power.

These dc power consumers, likewise, don’t have an ac-to-dc power stage and can use the dc power without any conversion. However, given there are no standard dc distribution networks, any equipment and the distribution network will need to be uniquely designed to work together. Naturally, cell formation or battery testers would be designed to work on this dc distribution bus, as they are the primary systems to benefit from dc distribution.

Reaping the Benefits of DC Regeneration

Charging from dc and regenerating back to dc can be more efficient by eliminating unnecessary power flow through the dc-to-ac and ac-to-dc stages. In those cases when there’s excess power from discharging cells/batteries, that power must run through a centralized bulk dc-to-ac inverter and go back on the ac line to be utilized by other ac equipment.

Likewise, when more systems are consuming dc power than is available via dc regeneration from discharging cells/batteries, then a centralized bulk ac-to-dc converter is needed. It pulls the necessary supplemental ac power from the ac grid and puts it back on the dc distribution network to supply the additional dc power.

In a large cell factory or battery testing lab, it may be feasible to schedule the charging and discharging functions to achieve a near balance of dc power supplier and dc power consumers. In this case, most of the power is recirculated within the dc distribution system, requiring little to no power to flow through the centralized ac-to-dc converters or dc-to-ac inverters. By minimizing power flowing between the dc distribution network and the ac distribution network, there are fewer losses through the ac power stages, resulting in balanced dc distribution having overall higher efficiency.

In addition, dc distribution makes it easier and more efficient to store excess dc power from regenerative discharging in stationary battery storage banks and then later use this stored energy for charging without having to use power from the ac grid. Utilizing this stored energy can lower operating costs to run the factory or testing lab by shifting the usage pattern of ac power, thus taking advantage of time-of-day ac power rates and lowering peak ac current demand charges.

If the stationary battery storage banks operate at a different dc voltage than the dc distribution network, then additional dc-to-dc converters are needed. Any savings could be nullified by losses and inefficiencies of required dc-to-dc power-conversion stages required to step up or step down the dc voltage when putting dc power into or taking it out of the stationary battery storage banks.

About the Author

Bob Zollo

Solution Architect for Battery Testing, Electronic Industrial Solutions Group

Bob Zollo is solution architect for battery testing for energy and automotive solutions in the Electronic Industrial Solutions Group of Keysight Technologies. Bob has been with Keysight since 1984 and holds a degree in electrical engineering from Stevens Institute of Technology, Hoboken, N.J. He can be contacted at [email protected].