Power-Quality Monitoring (Part 1): The Importance of Standards-Compliant PQ Measurements

Members can download this article in PDF format.

What you'll learn:

- What are parameters of power quality?

- Applications best served by PQ monitoring.

- Comparing Class A and Class S for measurement devices.

Power quality (PQ) has found renewed interest due to changing power-generation modes and consumption dynamics. Unprecedented growth in renewable sources at different voltage levels has compounded PQ-related issues.

Consumption patterns have also seen a wide transformation due to unsynchronized loads added at multiple entry points of the grid and voltage levels. Some examples include electric-vehicle (EV) chargers that can require hundreds of kilowatts, and the large number of data centers and their related equipment, such as heating, ventilation, and air conditioning. In industrial applications, arc furnaces that run by variable-frequency drives, switching transformers, etc., not only add a lot of unwanted harmonics to the grid, but are responsible for voltage dips, swells, transient brownouts, and flicker, too.

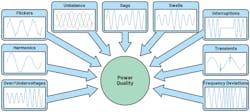

Power quality in the utility space refers to the quality of the voltage delivered to the consumer. A series of prescribed regulations for the magnitude, phase, and frequency determine this quality of service. However, by definition, it denotes both voltage and current. While the voltage is easily controlled by the generation side, the current is governed largely by consumer usage. The concept and implications of PQ issues are rather widespread, depending on the end-users (Fig. 1).

The economic impact of bad PQ has been studied and surveyed extensively in the last few years; its effects are estimated to be in the region of billions of dollars worldwide.1 All of these studies conclude that monitoring the quality of power has a direct impact on the economic results of many business sectors.

Even though it’s clear how bad PQ negatively affects the economics of business, monitoring it efficiently and effectively at scale is not an easy task. Monitoring PQ in a facility involves having highly trained personnel and expensive equipment installed on multiple points along the electric system for long or indefinite periods of time.

PQ Monitoring Areas of Application

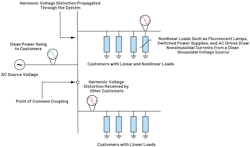

Power-quality monitoring is often seen as a cost-saving strategy for some business sectors and a critical activity for others. Power-quality issues can arise in a broad range of electric infrastructure (Fig. 2). As we’ll discuss later, PQ monitoring is becoming increasingly critical in spaces such as electric generation and distribution, EV charging, factories, and data centers.

Electricity Utility Companies, Electricity Transmission, and Distribution

Utility companies serve consumers with distribution systems such as generating stations, which are power substations that supply electricity via transmission lines. The voltage supplied via these transmission lines is stepped down to lower levels by substation transformers, which inject certain harmonics or interharmonics to the system. Harmonic currents in distribution systems can cause harmonic distortion, low power factor, and additional losses, as well as overheating in the electrical equipment,2 leading to a reduction in the lifetime of equipment and increases in cooling costs.

Nonlinear single-phase loads served by these substation transformers deform the current’s waveform. The unbalance of nonlinear loads causes additional losses on power transformers, additional load of neutrals, unexpected operation of low-power circuit breakers, and incorrect measurement of electricity consumed.3 Figure 3 illustrates the effect of these linear loads.

Electricity generation by wind and photovoltaic (PV) solar systems injected into the grid create several power-quality problems as well. On the wind generation side, wind intermittency generates harmonics and short-duration voltage variations.4 The inverters in PV solar systems create noise that can produce voltage transients, distorted harmonics, and radio-frequency noise because of the high-speed switching commonly used to increase the efficiency of the energy harvested.

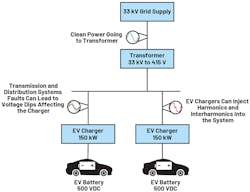

EV Chargers

Electric-vehicle chargers can face multiple power-quality challenges, both in power sent to and from the grid (Fig. 4). From a power distribution company perspective, power electronics-based converters used in EV chargers inject harmonics and interharmonics. Chargers with improperly designed power converters can inject direct currents (dc). In addition, fast EV chargers introduce rapid voltage changes and voltage flicker into the grid.

From the EV charger side, faults in transmission or distribution systems lead to voltage dips or interruption of supply voltage to the charger. Reduction of voltage from the EV charger tolerance limits will lead to activation of undervoltage protection and disconnection from the grid (which leads to a very bad user experience).5

Factories

Power-quality problems caused by power-supply variations and voltage disturbances cost approximately $119 billion (U.S.) per year for industrial facilities in the United States, as per an Electric Power Research Institute (EPRI) report.6 Moreover, 25 EU states suffer an equivalent of $160 billion (U.S.) in financial losses per year due to different PQ issues, according to the European Copper Institute.7 These figures are linked to subsequent downtime and production losses as well as the equivalent of intellectual productivity losses.8

Degradation of power quality is usually caused by intermittent loads and load variations from arc furnaces and industrial motors. Such disturbances give rise to surges, dips, harmonic distortions, interruptions, flicker, and signaling voltages.9

To detect and record these disturbances inside a factory installation, it’s necessary to have PQ monitoring equipment in several points throughout the electric installation or, even better, have it at the load level. With the arrival of new Industry 4.0 technologies, PQ monitoring at the load can be addressed by industrial panel meters or submeters to get a comprehensive view of the quality of the power delivered to each load.

Data Centers

Presently, most business activities depend on data centers in one way or another to provide email, data storage, cloud services, etc. Data centers demand a high level of clean, reliable, and uninterrupted electricity supply. PQ monitoring excellence helps managers prevent costly outages and helps manage equipment maintenance, or replacement, required due to issues on the power-supply units (PSUs).

The integration of uninterruptible-power-supply (UPS) systems into rack power distribution units (PDUs) represents another reason to add PQ monitoring to IT racks inside the data center. This integration can provide visibility to power issues at a power-socket level.

UPS system failure, including UPS and batteries, is the primary cause of unplanned data-center outages, according to a report by Emerson Network Power.10 Around a third of all reported outages cost companies nearly $250,000.11

UPS systems are used on every data center to ensure clean and uninterrupted power. These systems isolate and mitigate most of the power problems from the utility side, but they don’t protect against issues generated by the PSU of IT equipment itself. IT equipment PSUs are nonlinear loads that can introduce harmonic distortion in addition to other problems caused by equipment. They include those that can result in high-density cooling systems with variable-frequency speed-controlled fans.

Apart from these issues, PSUs also face interferences that come in multiple forms. Among them are voltage transients and surges; voltage swells, sags, and spikes; imbalance or fluctuations; frequency variation; and poor facility grounding.

PQ Standards Defined

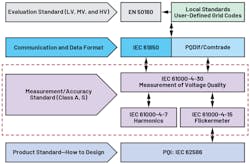

Power-quality standards specify measurable limits to the electricity magnitudes as to how far they can deviate from a nominal specified value (Fig. 5). Different standards apply to different components of the electricity system.

Specifically, the International Electrotechnical Commission (IEC), in the IEC 61000-4-30 standard, defines the methods for measurement and the interpretation of results of PQ parameters of alternating-current (ac) power systems. The PQ parameters are declared for fundamental frequencies of 50 and 60 Hz. This standard also establishes two classes for measurement devices—Class A and Class S:

- Class A defines the highest level of accuracy and precision for the measurements of PQ parameters and is used for instruments requiring very precise measurements involving contractual matters and dispute resolution. It’s also applicable to the devices that need to verify compliance of the standard.

- Class S is used for PQ assessment, statistical-analysis applications, and diagnostics of PQ problems with low uncertainty. The instrument in this class can report a limited subset of the parameters defined by the standard. The measurements made with Class S instruments can be done on several sites on a network, on complete locations, or even on single pieces of equipment.

It’s important to note that the standard defines the measurement methods, establishes a guide for the interpretation of the results, and specifies the performance of the power-quality meter (Fig. 6). It doesn’t provide guidelines on the design for the instrument itself.

The IEC 61000-4-30 standard defines the following PQ parameters for Class A and Class S measurement devices:12

- Power frequency

- Magnitude of the supply voltage and current

- Flicker

- Supply-voltage dips and swells

- Voltage interruptions

- Supply-voltage unbalance

- Voltage and current harmonics and interharmonics

- Rapid voltage change

- Underdeviation and overdeviation

- Mains signaling voltage on the supply voltage

Key Differences Between Class A and Class S Defined by the IEC 61000-4-30 Standard

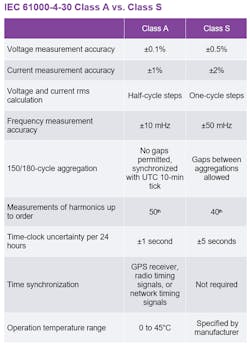

Although Class A defines higher levels of accuracy and precision than Class S, the differences are beyond just levels of accuracy. Instruments must comply with requirements such as time synchronization, quality of probes, calibration period, temperature ranges, etc. The table presents a list of requirements that instruments shall meet to be certified in one or the other class.

Conclusion

Power-quality issues are present across the whole electric infrastructure. Having equipment that monitors these PQ issues helps to improve performance, quality of service, and equipment lifetime while reducing economic losses. In Part 2, we’ll introduce an integrated solution and a ready-to-use platform that can significantly accelerate development and reduce costs for developing PQ monitoring products.

References

1. Panuwat Teansri, Worapong Pairindra, Narongkorn Uthathip Pornrapeepat Bhasaputra, and Woraratana Pattaraprakorn. “The Costs of Power Quality Disturbances for Industries Related Fabricated Metal, Machines and Equipment in Thailand.” GMSARN International Journal, Vol. 6, 2012.

2. Sai Kiran Kumar Sivakoti, Y. Naveen Kumar, and D. Archana. “Power Quality Improvement In Distribution System Using D-Statcom in Transmission Lines.” International Journal of Engineering Research and Applications (IJERA), Vol. 1, Issue 3.

3. Gabriel N. Popa, Angela Lagar, and Corina M. Diniş. “Some Power Quality Issues in Power Substation from Residential and Educational Buildings.” 10th International Symposium on Advanced Topics in Electrical Engineering (ATEE), IEEE, 2017.

4. Sulaiman A. Almohaimeed and Mamdouh Abdel-Akher. “Power Quality Issues and Mitigation for Electric Grids with Wind Power Penetration.” Applied Sciences, December 2020.

5. George G. Karady, Shahin H. Berisha, Tracy Blake, and Ray Hobbs. “Power Quality Problems at Electric Vehicle’s Charging Station.” SAE Transactions, 1994.

6. David Lineweber and Shawn McNulty. “The Cost of Power Disturbances to Industrial and Digital Economy Companies.” Electric Power Research Institute, Inc., June 2001.

7. Roman Targosz and Jonathan Manson. “Pan-European Power Quality Survey.” 9th International Conference on Electrical Power Quality and Utilisation, IEEE, 2007.

8. Subrat Sahoo. “Recent Trends and Advances in Power Quality.” Power Quality in Modern Power Systems, 2020.

9. A. El Mofty and K. Youssef. “Industrial Power Quality Problems.” 16th International Conference and Exhibition on Electricity Distribution, 2001. Part 1: Contributions. CIRED (IEE Conf. Publ No. 482), IEEE, June 2001.

10. “Cost of Data Center Outages.” Ponemon Institute, January 2016.

11. “Data Center Outages Are Common, Costly, and Preventable.” Uptime Institute.

12. IEC 61000-4-30:2015: Electromagnetic Compatibility (EMC)-Part 4-30: Testing and Measurement Techniques-Power Quality Measurement Methods.” International Electrotechnical Commission, February 2015.

About the Author

Jose Mendia

Senior Engineer, Product Applications, Analog Devices Inc.

Jose Mendia has a B.Sc. in electronics and computer science engineering and joined the Energy and Industrial System Group at Analog Devices in 2016. Currently, he is a senior engineer in product applications at the Edinburgh UK design center.