Triboelectric Nanogenerator Harvests Ocean-Wave Energy

What you’ll learn:

- The challenges faced by energy harvesting powered by ocean waves.

- How a new design overcomes the existing limitations.

- The tested performance of the new approach.

There seem to be no limits to the ingenious ways that designers are devising to harvest energy or take existing approaches and exploit and enhance them. It makes sense, as harvested energy is not only “free,” but also long-lasting. And, in many cases, it’s the most practical way to power a small or modest remote sensor-driven data-acquisition load.

Thus, using the widely available ocean-wave energy seems like a “no brainer.” However, the reality is that many practical issues must be overcome.

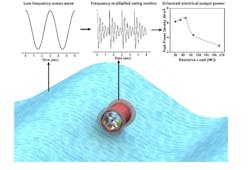

Now, a research team at the Pacific Northwest National Laboratory (PNNL) has developed a contact-separation mode triboelectric nanogenerator (TENG) with a simple structure for harvesting wave energy and powering marine sensors and transmitters. Although this isn’t the first cylindrical TENG (C-TENG)—several models are already in use—the PNNL team maintains that this design overcomes weaknesses of those existing ones.

Achieving Higher Frequency

The key is a new mechanism for wave-driven energy-harvesting TENGs that can convert the low-amplitude, low-frequency ocean waves into high-frequency mechanical motion for more effective power generation (Fig. 1). This new TENG must be able to operate and be triggered by any wave conditions, even in the middle of the ocean where waves have uniform or random low amplitude and frequency.

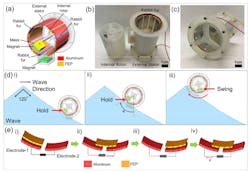

Water wave-energy harvesting with pendulum-structured TENGs fall into two types, using either contact-separation or free-standing layer modes. The contact-separation mode generates electricity as the triboelectric-induced charge transfer occurs when two layers of opposite charges come into contact periodically in the presence of an external mechanical force.

A free-standing layer mode TENG consists of dielectric materials and electrodes. It generates electricity when the dielectric material slides over the electrodes, which induces the triboelectric charge transfer across the electrodes.

This novel C-TENG is designed to increase the operating frequency of the TENG using low-frequency, uniform water waves to increase the power generation. The new frequency-multiplied cylindrical TENG (FMC-TENG) converts the low-frequency wave energy into potential energy using a proof mass held by the repulsive force of two magnets.

Whenever the restoring force (weight) of the proof mass exceeds the magnetic force, the potential energy of the proof mass is transformed into kinetic energy via a high-frequency swing motion for generating high output power.

TENG Construction

The FMC-TENG includes two main components: an internal rotor and an external stator (Fig. 2). The cylindrical stator is manufactured from a UV-curing resin, using a stereolithography 3D printer. The internal rotor has an outer diameter (OD) of 43 mm, while the external stator has an inner diameter (ID) of 44 mm and a thickness of 1.72 mm.

Aluminum electrodes are attached to its inner wall and a neodymium magnet is secured to the bottom of the stator. To enhance the output performance, a soft-contact mechanism between fluorinated ethylene propylene (FEP) and rabbit fur is attached in the FMC-TENG. The outer surface of the internal rotor contains six extruded rectangular ridges (70 × 10 × 1 mm), each covered with FEP film (0.05 mm thick).

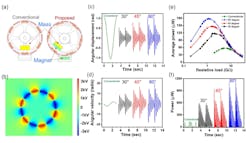

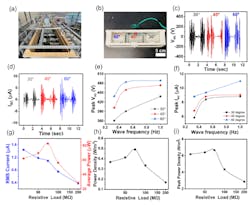

Work on the project began with semi-analytical modeling of the FMC-TENG to theoretically verify the effectiveness of the FMC-TENG (Fig. 3). Then, the electrical characteristic of the C-TENG was evaluated by comparing it with a conventional C-TENG using a wave-motion simulator that mimics the wave motion in the ocean.

Test Results

Final optimization of the FMC-TENG was performed in a 12-meter-long water tank with adjustable wave height and frequency (Fig. 4). The peak power density of the FMC-TENG reached 6.67 W/m3 at a wave frequency of 0.33 Hz.

The device sustainably powered up an array of 27 LEDs and was able to charge up a capacitor up to 1.8 V for driving an acoustic transmitter (Fig. 5). They also tested and compared the new design to existing C-TENG implementations.

This patent-pending design is detailed in their 16-page paper “Frequency-multiplied cylindrical triboelectric nanogenerator for harvesting low frequency wave energy to power ocean observation system” published in Nano Energy. While it’s behind a paywall, just click on the button “View Open Manuscript” at the top to see the entire paper.

About the Author

Bill Schweber

Contributing Editor

Bill Schweber is an electronics engineer who has written three textbooks on electronic communications systems, as well as hundreds of technical articles, opinion columns, and product features. In past roles, he worked as a technical website manager for multiple topic-specific sites for EE Times, as well as both the Executive Editor and Analog Editor at EDN.

At Analog Devices Inc., Bill was in marketing communications (public relations). As a result, he has been on both sides of the technical PR function, presenting company products, stories, and messages to the media and also as the recipient of these.

Prior to the MarCom role at Analog, Bill was associate editor of their respected technical journal and worked in their product marketing and applications engineering groups. Before those roles, he was at Instron Corp., doing hands-on analog- and power-circuit design and systems integration for materials-testing machine controls.

Bill has an MSEE (Univ. of Mass) and BSEE (Columbia Univ.), is a Registered Professional Engineer, and holds an Advanced Class amateur radio license. He has also planned, written, and presented online courses on a variety of engineering topics, including MOSFET basics, ADC selection, and driving LEDs.