This Week in PowerBites: Silicon Caps, Smart Nomograms, and H2 from Seawater

This article is part of the This Week in PowerBites Library Series.

Novel Visual Parameter Calculation Technique for DCM Flyback Converters

DCM flyback designs based on a Pulsiv OSMIUM AC-to-DC front end eliminates the switching losses under low load conditions and poor average efficiency, which occurs when conventional DCM flybacks are paired with a boost PFC front-end stage. However, it involves a lengthy set of calculations to optimize component values. This visual, nomogram-based technique can replace more complex equation-based methods, providing a fast and accurate visual process for identifying primary-side inductance and minimum duty cycle.

This innovative tool is available to download free from the Pulsiv website here, along with the above supporting tutorial video, which provides a visual guide for how to use the nomogram effectively.

*About nomograms

The field of nomography was invented in 1884 by French engineer and mathematician Philbert Maurice d’Ocagne. It provides engineers with a precise and practical method for calculating complicated formulas using a parallel coordinate system. Results from a nomogram are obtained quickly and reliably by simply drawing one or more lines, without needing to solve algebraic equations.

High-Current Motor-Drive Series Offers Flexible Power-Stage Configuration and Tunable Drive Modes

The first members of STMicroelectronics’ STSPIN9 series of high-current motor-drive series target high-end industrial and home and professional appliances. The 4.5-A STSPIN948 and 5.0-A STSPIN958 integrate pulse-width-modulation (PWM) control logic and a 58-V power stage with system protection and two operational amplifiers for current sensing. Suitable for driving brushed DC motors and bipolar stepper motors, both ICs offer flexibility and scalability while streamlining the bill of materials.

The STSPIN948 contains two full bridges that can be configured to work in different modalities, giving developers flexibility to drive multiple and differently rated motors in several configurations. With a choice of current control based on PWM with fixed off-time or a programmable threshold, the STSPIN948 can be used in five different modes. This 4.5-A IC is packaged as a 7- × 7-mm VQFPN48.

The STSPIN958 contains a single full bridge that can be configured to drive two unidirectional motors, one bidirectional brushed DC motor, or one higher-current unidirectional motor by parallelizing the outputs. With the same choices of fixed off-time and programmable current control, as well as dual half-bridge, single full-bridge, and half-bridge parallel connections, this IC supports seven different driving methods. The 5.0-A STSPIN958 comes in a 5- × 5-mm VFQFPN32 package.

With their wide operating-voltage range and flexibility, the STSPIN948 and STSPIN958 motor drivers can be used in a variety of industrial applications. These include factory automation systems, textile machines, industrial and home robots, stage lighting, ATM and money-handling machines, antenna controllers, vending machines, and most common home and industrial appliances.

Both drivers let the designer program the output transistors’ slew rate to 0.3, 0.6, 1.2, or 2 V/ns using an external resistor, to guarantee the best tradeoff between power consumption and electromagnetic-compatibility targets. Dead time is built in to prevent shoot-through and each MOSFET’s on-resistance of only 200 mΩ helps maximize operating efficiency. The very short propagation delay, at 280 ns, ensures fast dynamic response to system commands.

Each IC benefits from a complete set of protection features including overcurrent, over-temperature, and short-circuit protection, plus low bus-voltage detection with undervoltage lockout (UVLO).

Rapid application development is supported by the devices' easy-to-use evaluation boards. The EVSPIN948 drives up to two motors using the STSPIN948, while the EVSPIN958 drives a single motor with the STSPIN958. Each is designed for use as an expansion card and is compatible with most STM32 Nucleo boards as well as the Arduino UNO R3 connector.

Both devices are in production now, available from $1.42 for the STSPIN958 and $2.35 for the STSPIN948, for orders of 1,000 pieces. Visit www.st.com/stspin for more information.

1250-V GaN Switcher IC Provides Efficient Accessory Power for Industrial and Utility Apps

According to Power Integrations, it now offers the world’s highest-voltage, single-switch, gallium-nitride (GaN) power-supply IC, featuring a 1250-V GaN switch device. InnoSwitch3-EP 1250-V ICs are the newest members of the InnoSwitch family of offline CV/CC QR flyback-switcher ICs, which feature synchronous rectification and the company’s FluxLink safety-isolated feedback technology.

The switching losses for Power Integrations’ proprietary 1250-V PowiGaN technology are less than a third of that seen in equivalent silicon devices at the same voltage. This results in power-conversion efficiency as high as 93%, enabling highly compact flyback power supplies that can deliver up to 85 W without a heatsink.

Designers using the new InnoSwitch3-EP 1250-V ICs can specify an operating peak voltage of 1,000 V, which allows for industry-standard 80% derating from the 1250-V absolute maximum. This provides significant headroom for industrial applications and is particularly valuable in challenging power-grid environments where robustness is an essential defense against grid instability, surge, and other power perturbations.

Samples are available now; volume-shipment lead time is 16 weeks. Pricing for InnoSwitch3-EP 1250-V devices in the INSOP-24D package starts at $3.00 for 10,000-unit quantities. A reference design, DER-1025, describing a 12-V, 6-A flyback converter, is available for free download.

For further information, contact a Power Integrations sales representative or one of the company’s authorized worldwide distributors—DigiKey, Newark, Mouser and RS Components—or visit power.com.

Silicon Capacitors Offer Better Performance, Smaller Size, Longer Life than Ceramics

Silicon semiconductor processing technology cultivated over many years has enabled higher performance in a smaller size. Such is the case with the new BTD1RVFL series silicon capacitors from ROHM Semiconductor, which are increasingly finding homes in smartphones and wearable devices.

Silicon capacitors using thin-film semiconductor technology can provide higher capacitance in a thinner form factor than existing multilayer ceramic capacitors (MLCCs). At the same time, stable temperature characteristics, along with excellent reliability, are accelerating their adoption in a variety of applications.

ROHM’s silicon capacitors, manufactured using the company’s proprietary RASMID miniaturization technology, allow for processing in 1-µm increments, eliminating chipping during external formation and improving dimensional tolerances within ±10 µm. This small variation in product size enables mounting with a narrower distance between adjacent components. At the same time, the backside electrode used to bond to the substrate has been expanded to the periphery of the package to improve mounting strength.

The first series in the lineup, the BTD1RVFL series (BTD1RVFL102/BTD1RVFL471), consists of the industry’s smallest mass-produced surface-mount silicon capacitors. The mounting area is reduced by approximately 55% over general 0201-size (0.2 × 0.1 in.)/0603-size (0.6 × 0.3 mm) products to just 0.08 mm2, contributing to greater application miniaturization. Moreover, a built-in TVS protection element ensures high ESD resistance that minimizes the number of person-hours required for surge countermeasures and other circuit design elements. Applications include smartphones, wearables, compact IoT devices, optical transceivers, etc.

Automatically Resettable Mini Thermal Cutoff (TCO) Features Protection and Sensing

The Bourns Model SW mini-breaker is the company's smallest surface-mount mini-breaker TCO device. With a 4.7- × 2.8-mm footprint and a height of just 0.94 mm, it’s designed to control abnormal, excessive temperature virtually instantaneously, up to rated limits. The device can also be used as an overtemperature sensor. Anticipated applications include LED systems, wireless-charging coils, motors, and a variety of PCB components.

The new Model SW mini-breaker complements Bourns' latest Model SD Series with features and functionality that meet lower current-protection application requirements, including a trip temperature setting of 70°C ±5°C, with maximum resistance values of 5 mΩ. For wireless-charging applications, it can operate up to 100 V peak (AC 128 kHz).

Manufactured using Bourns' highest-rated corrosion-resistant bimetal mechanism, this mini-breaker model is also designed to withstand humid environments. For detailed product information, go here.

Automotive PMICs Integrate CAN FD and LIN for Simpler Car-Body Controllers

STMicroelectronics' SPSB081 automotive power-management IC (PMIC) integrates a set of power sources and transceivers to help simplify the design of car-body controllers for a sunroof, seats, tailgate, doors, and lighting modules. Underscoring their adaptability, the controllers are also used in gateways, HVAC controllers, passive keyless-entry systems, telematic control units, and control panels.

The PMIC is a veritable a Swiss Army knife for automotive designers, including features such as a main fixed-voltage low-dropout regulator (LDO), a secondary programmable LDO, four high-side drivers, a CAN FD transceiver, and an optional LIN transceiver. The ICs provide multiple standby modes with very low quiescent current and programmable local or remote wake-up to help minimize power consumption.

The PMIC family has several variants, such as the SPSB081C3 and SPSB081C5, which contain a 3.3- or 5-V fixed LDO, respectively, with one CAN transceiver. The SPSB0813 and SPSB0815 incorporate the additional LIN transceiver. The secondary LDO, included in all variants, can be programmed through the IC’s SPI port to operate as an independent 3.3- or 5-V regulator, or to track the main LDO. The four high-side drivers can source up to 140 mA to power LEDs and sensors, with current monitoring and a 10-bit PWM timer for each channel.

Extensive built-in thermal and electrical protection is provided, as well as a diagnostic output pin for fail-safe signaling. These features support applications that must satisfy functional-safety requirements in accordance with ISO 26262, even if not designed as a safety hardware element. All outputs have overcurrent protection and open-load fault indication.

The SPSB081 family is AEC-Q100 qualified, specified from −40 to 150°C, and able to operate up to 175°C. All variants are in production and available in a thermally enhanced, 5- × 5- × 1-mm QFN32L package, from $1.80 for orders of 1,000 pieces.

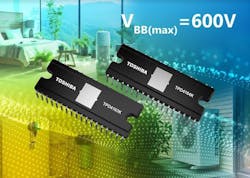

600-V-Rated IPDs for BLDC Motor Drives Offer Flexibility and Through-Hole Packaging

New members were added to a family of intelligent power devices (IPD) developed by Toshiba Electronics Europe that targets brushless DC (BLDC) motor-drive applications, such as pumps, air conditioning, ventilation, and fans. These latest additions to the recently launched TPD4163F and TPD4164F (TPD4163K and TPD4164K) use a HDIP30 through-hole package measuring just 32.8 × 13.5 × 3.525 mm, which can reduce its PCB mounting area by over 20%, when compared to Toshiba’s DIP26 products.

As with their other family members, the new IPDs are based on 600-V-rated IGBTs and include a matched gate driver to deliver a complete, integrated solution in a compact package. The TPD4163K has a maximum DC current (IOUT(max)) rating of 1 A, and the more capable TPD4164K is rated at 2 A. IGBT saturation voltage (VCEsat) of the devices is 2.6 V and 3.0 V, respectively, and the diode forward voltage (VF) is 2.0 V and 2.5 V.

The maximum supply voltage rating (VBB(max)) of both devices is now 600 V, which increases the design margin. This enhancement is particularly useful in locations where mains power is variable or subject to fluctuations.

To ease the task of designing BLDC motor drives, Toshiba announced a reference design that showcases the capabilities of the new TPD4164K and TMPM374FWUG microcontroller with a vector control engine.

The TPD4163K and TPD4164K are available for volume shipments and the reference design board is also fully available.

Prototype Demonstrates Practical Over-the-Air Charging for Remotes, Sensors, and Other Small Devices

Powercast and Nichicon recently unveiled a prototype of a wirelessly charged active stylus as part of a collaboration to add radio-frequency (RF) charging capabilities to Nichicon's new small lithium-titanate-oxide (LTO) rechargeable batteries (SLBs).

To demonstrate how to design small, sustainable, rechargeable-battery-based devices that can reduce both disposable battery e-waste and expensive battery maintenance, the companies paired Powercast's over-the-air (OTA) RF wireless charging technology with Nichicon's SLB. Together, they can fit into small devices such as styluses, wireless thermometers, medical devices, and IoT sensors.

In the slim stylus demo, Powercast's tiny receiving antenna and Powerharvester PCC110 RF-to-DC converter chip embedded in the stylus harvests RF sent over the air from Powercast's Ubiquity transmitter. It’s then converted to DC to wirelessly recharge Nichicon's embedded SLB04255L040 battery. Subsequently, the battery powers the flashlight LED at the end of the stylus, with RF technology recharging the battery when it's not in use.

"Wirelessly powered, sustainable devices help solve the environmental problem of disposable batteries that litter landfills and release toxins, and the inconvenience and expense of battery replacement," said Charles Greene, PhD, COO, and CTO of Powercast.

Boost/SEPIC Controller Enables 50-kHz LED-Wide PWM Dimming in Automotive Lighting

Diodes Inc. introduced a boost/single-ended primary inductance converter (SEPIC) controller for automotive LED applications. The AL8853AQ is an automotive-compliant and highly integrated boost/SEPIC controller that provides high performance with a reduced bill of materials (BOM) in automotive LED applications, including exterior lights, headlamps, head-up displays (HUDs), and backlight displays.

The wide input range (6 to 40 V) of the AL8853AQ supports a typical 12-V vehicle battery voltage input. Its 200-mV feedback reference voltage has ±3% tolerance to maintain tight brightness control while improving efficiency. The fixed 400-kHz switching frequency of the AL8853AQ supports low electromagnetic interference (EMI) by using a fundamental frequency outside the medium-wave (MW) band.

In addition, this controller’s fast (50 kHz) PWM to analog dimming mode (100% down to 1%) prevents visible low- or high-frequency flickering usually associated with PWM dimming. The AL8853AQ also includes robust protection features to guard against unexpected overvoltage, overcurrent, overtemperature, and diode and inductor short-circuit events.

The AL8853AQ is qualified to AEC-Q100 Grade 1, manufactured in IATF 16949 certified facilities, and is PPAP capable. This controller is available in a SO-8 package at $0.33 in 1,000-piece quantities.

Hydrogen from Seawater? Early Research on Saltwater Electrolysis is Underway

Researchers from the University of Guam (UOG) and Pacific Northwest National Laboratory have begun work to evaluate the potential for converting seawater into hydrogen energy. The work is being conducted under the Department of Reaching a New Energy Sciences Workforce (RENEW) program, created specifically to provide research partnerships between the national laboratories and educational institutions that serve populations historically underrepresented in science, such as Pacific Islanders.

Video credit: Eddie Pablo | Pacific Northwest National Laboratory

The RENEW funding enabled a small group of two UOG undergraduate civil engineering students and their mentor, John Limtiaco, an assistant professor of chemistry at the UOG, to spend the summer of 2023 at PNNL. During their stay in Richland, they’re investigating the complexities of seawater electrolysis.

Since seawater is more than just water—it includes salt, metals, and carbon-based molecules—the researchers must consider how each different component reacts with electricity. The team is focusing on how the carbon-containing molecules naturally found in seawater could deter the formation of potentially toxic chlorine gas while increasing hydrogen production.

Currently, the team from UOG is focused on learning electrochemistry techniques to take back to Guam to study seawater electrolysis. The full experimental setup at PNNL is a perfect test ground for the UOG researchers. They can explore all types of electrochemistry measurements, run baseline testing, and determine the most effective measurements to perform for the rest of the project when they return to UOG. The team is using model solutions to create a set of standards to compare them against more complex systems and the new setups in Guam.

Read the full story on PNNL's website.

Read more articles in the This Week in PowerBites Library Series.

About the Author

Lee Goldberg

Contributing Editor

Lee Goldberg is a self-identified “Recovering Engineer,” Maker/Hacker, Green-Tech Maven, Aviator, Gadfly, and Geek Dad. He spent the first 18 years of his career helping design microprocessors, embedded systems, renewable energy applications, and the occasional interplanetary spacecraft. After trading his ‘scope and soldering iron for a keyboard and a second career as a tech journalist, he’s spent the next two decades at several print and online engineering publications.

Lee’s current focus is power electronics, especially the technologies involved with energy efficiency, energy management, and renewable energy. This dovetails with his coverage of sustainable technologies and various environmental and social issues within the engineering community that he began in 1996. Lee also covers 3D printers, open-source hardware, and other Maker/Hacker technologies.

Lee holds a BSEE in Electrical Engineering from Thomas Edison College, and participated in a colloquium on technology, society, and the environment at Goddard College’s Institute for Social Ecology. His book, “Green Electronics/Green Bottom Line - A Commonsense Guide To Environmentally Responsible Engineering and Management,” was published by Newnes Press.

Lee, his wife Catherine, and his daughter Anwyn currently reside in the outskirts of Princeton N.J., where they masquerade as a typical suburban family.

Lee also writes the regular PowerBites series.