Digging Deeper: Little-Known Aspects of High-Voltage Technology

Members can download this article in PDF format.

What you'll learn:

- The water-tree effect in subsea cables.

- What is macTaM education?

- Accuracy of current sensors in EV charging.

Of course, most engineers know the main principles of high-voltage technology and how they apply to design. This article reaches further into this arena, looking at some of the less-discussed, but nonetheless important, areas of HV technology.

Let’s begin with “water treeing.” This little-known mechanism is a degradation mechanism in a subsea cable’s insulation. It involves the formation of dense networks of channels and micro-voids that become filled with water.

The Water Tree

The water tree is a structure that’s the size of a human hair. As time passes, it could cause the disintegration of many kilometers of a subsea power cable. A water tree forms sites in which an electric field is increased locally, and it ultimately leads to surpassing the breakdown strength of the subsea cable insulation.

Without a water-protective lead barrier, water trees will be able to grow in significant numbers and lengths in today’s HV cross-linked polyethylene (XLPE) subsea power cables. Although no contaminations or defects have been observed at the smooth interface where the water trees initiate, engineers saw, via scanning transmission electron microscopy-energy dispersive X-ray spectroscopy (STEM-EDS), that inorganic impurities are present both in the water tree as well as directly below its inception site.

It will be quite interesting to see if the same elements appear when there are no water trees, thus indicating that these may be directly related to the water-treeing effect.

Subsea Cables

Inter-array subsea cables are being used to transmit the energy harvested offshore, such as from a wind turbine to an offshore substation. The Prysmian Group presently leads the way in technological development, being the first to market with 66-kV inter-array cable systems under a Carbon Trust program in the UK. These cables will meet the requirements of offshore wind park developers with capital expenditure reductions as high as 15% for their projects.

macTaM

macTaM2 (mobile and compact high-voltage test and measurement) educates personnel at higher education facilities in the field of high-voltage engineering without the need of a cost- or resource-consuming high-voltage laboratory.

The development of the presented macTaM test and measurement facility is based on a unique concept in which powerful lab teaching, in the field of high-voltage engineering, is performed with a group of 15 students and one supervising teacher or professor within a typical classroom environment. The group of 15 students can be divided into five student teams. During one teaching session (180 minutes of lab time + 15-minute break), a student team will be working on one lab module.

High-Voltage Cable Sections in Overhead/Underground Line-Transmission Systems

XLPE cables are critical elements in power-supply grids. These cables are applicable to power-distribution networks as well as other fields. They offer significant advantages over PVC insulated cables, including simplicity in structure, lightweight, heavy load capacity, adequate heat resistance, non-melting, chemical corrosion resistance, and high mechanical strength.

New developments of high-voltage XLPE cables make it possible to employ this technology for extra-high-voltage (EHV)-level applications in transmission networks.3 EHV insulated cables are used in underground power circuits that have three-phase AC voltage.

EHV insulated cables operate at rated voltages of 66, 110, and 132 kV. These cables are also typically used in the transmission lines that lie between two units of an electrical distribution grid, a generator unit, and a distribution unit, or inside a station or substation. Such insulated cable circuits can be used with overhead high-voltage power lines as well.

Referred standards are IEC 60840/IS 7098 Part 3/IEC62067.

Current Sensing in EV High-Voltage Charging Systems

Electric vehicles (EVs) are a fast-growing sector in the automotive industry, especially in California with 250,000 electric vehicles sold in 2022. In fact, 42% of EVs in the United States are sold in California.

The accuracy that current sensing provides in an EV charger, especially with simple-to-use sensors that perform directly in high voltage circuitry, is key to high-voltage systems. That’s because these sensors can provide accurate readings faster than most other sensing methods.6

Good sensors lead to high-voltage system safety. Such high-voltage sensors typically have the following features:

- A powerful integrated isolation barrier having withstand voltages in the range of 3 kV RMS with an isolation working voltage around 500 V RMS.

- An isolation barrier greater than 50 years.

- Temperature accuracy should be in the range of ±2°C maximum in the -40°C to +150°C

- An operating power-supply voltage range of 2.3 to 5.5 V.

- A quick-acting thermal response under 2 seconds.

- Short-circuit protection.

- A typical low power consumption of 9 µA.

- A small package such as an SOIC-7.

Medical Imaging

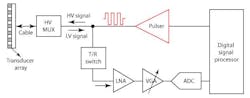

Medical ultrasonic imaging uses no radiation and isn’t destructive to the human body. Ultrasound transducer arrays create high-voltage pulses that are greater than 50 V p-p, while the ultrasound transducer frequency typically ranges from 1 to 15 MHz (see figure).

In the case of frequency resonance, the voltage at both ends of an ultrasonic transducer is the lowest at around 800 V. A 1500-W ultrasonic transducer needs an excitation voltage of 1000 to 2000 V from an ultrasonic generator to drive it.

The transducer can be affected by any switching frequency noise within this range. If intermodulated frequencies are within the pulsed-wave Doppler (PWD) and continuous-wave Doppler (CWD) spectrums, which range from 100 Hz to 200 kHz, the noticeable noise spectrums will materialize in the Doppler images. This is unacceptable within the ultrasound system.

References

1. “Tracking down the cause of water tree issues in wet design high voltage subsea cables,” Sofie Brantzæg Hårberg, Sintef.com.

2. “MACTAM-Mobile and Compact High Voltage Test and Measurement Facility for Educational Purposes,” 2023 4th International Conference on High Voltage Engineering and Power Systems (ICHVEPS).

3. “Aspects of High Voltage Cable Sections in Modern Overhead Line Transmission Systems,” T. Judendorfer, S. Pack, M. Muhr, Graz University of Technology Institute of High Voltage Engineering and System Management, 2008 International Conference on High Voltage Engineering and Application, Chongqing, China, November 9-13, 2008.

4. EHV Power Cable, CMI Limited.

5. “Breakdown characteristics of water tree defects under 0.1Hz cosine square wave voltage,” Dewen Zhang (State evaluation center Heilongjiang electric power research institute), Wei Wang, Zhiqiang Qi,Feng Wu, Lianming Chen, Key Laboratory of high voltage and EMC, Beijing North China electric power university, 2020.

6. Why accurate and reliable high-voltage sensing is important to the future of electrification, Texas Instruments

7. “A High-Speed High-Voltage Bipolar Pulser for Medical Ultrasonic Imaging Applications,” Yen-Chung Huang, Kuo-Tso Chen, Kuan-Yi Lu, Jian-Chiun Liou, and Guo-Zua Wu, Biomedical Technology and Device Research Labs, Industrial Technology Research Institute, Hsinchu, Taiwan, 2018 IEEE International Conference on Consumer Electronics-Taiwan (ICCE-TW).

About the Author

Steve Taranovich

Freelance Technical Writer, Phoenix Information Communication LLC

Steve is a contributing editor to Electronic Design.

Author of the non-fiction “Guardians of the Right Stuff,” a true story of the Apollo program as told by NASA and Grumman Corp. engineers, an astronaut, and technicians.

Experienced Editor-In-Chief of EETimes/Planet Analog and Senior Technical Editor at EDN running the Analog and Power Management Design Centers from 2012 to 2019.

A demonstrated history in electronic circuit design and applications for 40 years, and nine years of technical writing and editing in industry. Skilled in Analog Electronics, Space-related Electronics, Audio, RF & Communications, Power Management, Electrical Engineering, and Integrated Circuits (IC).

1972 to 1988 worked as a circuit design engineer in audio (8 years) and microwave (8 years). Then was Corporate Account Manager/applications engineer for Burr-Brown from 1988 to 2000 when TI purchased Burr-Brown. Worked for TI from 2000 to 2011.

Strong media and communication professional with a BEEE from NYU Engineering in 1972 and an MSEE from Polytechnic University in 1989. Senior Lifetime member of IEEE. Former IEEE Long Island, NY Director of Educational Activities. Eta Kappa Nu EE honor society member since 1970.