Understand Efficiency Ratings Before Choosing An AC-DC Supply

Greater efficiency in an ac-dc supply—what’s not to like? Everyone knows it’s a good thing and increasingly a priority. The decision process is straightforward: look for the supply with the dc output (volts/amps) you require, in a suitable form factor, and be sure it has the minimum efficiency your design (and regulatory agencies) require, all at a price that meets your bill of materials (BoM) mandate.

But before you make that decision, it’s important to ask two questions:

• What are the implications of an extra point or two in efficiency to design?

• What do those vendor numbers actually mean?

Efficiency’s Virtues—And Cost

It’s obvious that increased efficiency results in lower ac power costs for a given output. But for most applications, the operating savings for a supply in the 200- to 500-W class are quite modest, though they can’t be ignored.

Instead, look at the larger system implications of efficiency by flipping the issue over to inefficiency. A supply that is 90% efficient is 10% inefficient, of course, while one that is 92% efficient is just 8% inefficient. That’s basic math. Thus, a difference of only two percentage points in efficiency/inefficiency also means that the 92% supply is one-fifth less inefficient than the 90% supply, and that’s a big difference.

This apparently small difference in efficiency has system-level implications. Clearly, there's less heat stress on the supply itself as well as on the entire product, and heat is what drives down the mean time between failures (MTBF) of electronics.

Less heat also gives you flexibility in supply and system placement. Consider the increasingly popular IEEE 802.3at-2009 Power over Ethernet Plus (PoE+). Under this standard, all the operating power for the remote device comes from a chassis and control unit located not at the supplied device, but at a hub, often physically situated in an office cabinet. Those extra watts of heat can complicate placement and can rule out preferred locations or require additional cabinet cooling.

The PoE+ numbers make this dramatically clear. While 12.95 W per device was specified as sufficient for the original PoE applications such as standard Voice over Internet Protocol (VoIP) phones, security cameras, and wireless access points, the upgraded PoE+ standard calls for up to 25.5 W per device. Since a typical PoE+ system may have tens of remote devices, the total amount of power to be supplied—and, more important, resultant dissipation due to inefficiency—can be unpleasantly high.

Another major benefit of greater efficiency is that the designer may be able to go from a forced (active) cooled supply using fans to a passive, convection-cooled unit. This reduces upfront cost, increases system reliability, and decreases product noise. In fact, designers will often select a supply that is rated with active cooling for higher power than they need, then derate it and use it with convection cooling alone.

If this is an attractive option, it’s important to make sure that the supplier provides both forced and passive ratings. For example, the XL375 from N2Power is rated at 375 W with active cooling, but is also available fully characterised for convection cooling operation as a 260-W unit as the XL375CC supply (Fig. 1).

1. The XL375 ac-dc supply from N2Power is rated at 375 W with forced-air cooling. It’s also specified as a 260-W unit (designated the XL350CC) with passive, convection-only cooling, which is preferable in many applications.

Checking The Specs

As with most numbers that define a product, there are various operating conditions and perspectives that engineers selecting supplies should take into account. This goes beyond the usual advice to compare supplies under identical or similar conditions. New standards and certifications such as 80 Plus and the Gold Standard make such comparisons easier by providing a standard specification framework and starting point.

First, when you’re looking at an “efficiency up to x%” rating, check if it’s for a single-load “sweet spot” and line voltage. It’s possible for a supply that’s 80% to 90% efficient at a higher line voltage (240 V ac rms) to measure as low as 70% at 120 V ac. Keep in mind that with nominal 100-V (yes, there are places with 100 V), 120-V ac, and 230-V ac mains and their allowable bands, you may be looking at 85-V ac to 264-V ac operation. Also, check the temperature and airflow that the efficiency is measured at, since they may differ between suppliers.

In addition, so-called universal supplies, which handle both nominal 120 V ac and 240 V ac, will likely have different ratings than supplies optimised for only a single ac line value. This is because, in general, the greater the differential between ac input and dc output voltages, the more efficient a supply can be.

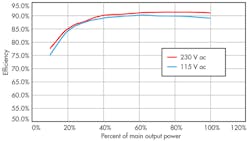

Efficiency across the load range is important too. Most supplies are far less efficient when operating well below their rated maximum output and achieve their highest efficiency closer to maximum output. If your application has a relatively constant load, the task of comparing supplies for overall efficiency is easier than if you have wide-ranging minimum/maximum loads. Fortunately, newer supply designs can maintain relatively flat efficiency across a wider span of their load range (Fig. 2).

2. A supply such as the XL350 (12-V output) maintains high, nearly constant efficiency from full load down to 40% of maximum, with only a small, further decrease even with a load of just 20% of maximum rating.

Power factor correction (PFC) also affects efficiency. Regulatory requirements are dictating better power factor performance, and the required power factor minimum increases with the supply’s power rating. For most supply designs, striving for higher PFC—closer to unity—adversely affects efficiency.

Therefore, it’s important to look at efficiency alongside the concurrent PFC rating. A supply rated at a higher efficiency may be doing so at a lower achieved PFC value than a supply that’s less efficient. Note that efficiency is easier to achieve at higher ac mains values than at lower ones. Earlier PFC designs did better at lower mains voltages. There is a tradeoff between efficiency and PFC.

Also, clarify what the ac line input to the supply looks like for these efficiency and PFC ratings. Though you might assume that a pure sine wave is used, that is actually a misleading model of reality. The ac line is not at all clean and has harmonics of the basic 50/60-Hz frequency. Advances in supply topologies and ICs, along with the use of digital signal processing (DSP) in the supply closed-loop control, have helped to improve overall performance.

Conclusion

Improved power-supply efficiency is a virtue. But as you make your supply decision, step back and ask yourself what an extra few percentage points is worth. It may be a lot, especially if it allows you to go to passive cooling. Also, clarify how the stated efficiency is measured, under what nominal line and load conditions, and what other factors may affect the validity and credibility of the nominal numbers you are quoted.

Don Knowles joined N2Power as vice president of engineering 12 years ago after more than two decades of experience in power electronics design and manufacturing spanning the industrial, ICT, and medical electronics sectors. Prior to joining N2Power, he ran his own power electronics business for 20 years, designing power supplies and high-power ac and dc loads, and working with contract manufacturers. He holds a degree in electronics from American River College, Sacramento, Calif., U.S.