The electric vehicle has been around for more than a century. Its most critical subsystem has always been the propulsion system, which includes three main components: a power converter, the propulsion motor, and an energy storage system. Also known as the battery, the energy storage system supplies energy to the electric motor, which then converts that energy to mechanical energy to provide power traction to the wheels.

Related Articles

- Drive Trains Face Unique Challenges In Electric Vehicles

- Understanding U.S. And European Standards For Electric Vehicle Charging

- Here Comes Electric Propulsion

Batteries are the most widely used energy storage system in electrical vehicles, but they’re not the only ones.A lot of research and development also has gone into using fuel cells as a power source for electrical vehicles. So what’s the difference?

Both use a chemical reaction to create electricity.A battery stores chemical reactants, while a fuel cell uses reactants that are stored externally.Once a battery is used up, it’s either thrown away or recharged.A fuel cell can continue to produce electricity as long as it has a fuel source and the stack is in working order.A vehicle powered by a battery is recharged, while a vehicle powered by a fuel cell is refueled.

It’s not an either/or proposition. Just as plug-in hybrid electric vehicles (PHEVs) use both gasoline and a battery to power their propulsion, there are opportunities for batteries and fuel cells to work together.Nevertheless, both power sources have barriers to widespread adoption. In the long term, though, batteries have more potential as a viable power source for electrical vehicles than fuel cells since they have overcome the necessary technology hurdles.

Bad Battery Memories

The battery has a long history that comes with connotations that cloud people’s perceptions of electrical vehicles. These perceptions have slowed the adoption of both PHEVs and battery electric vehicles (BEVs).The general public’s anxiety over battery technology also has created trepidation among automakers as to whether it makes sense to push ahead with the development of electric vehicles.

The problem is memory.Battery technology has evolved.What was true a decade ago is not true today.For example, no batteries today have a “memory effect.” But if you’re a child of the 1980s, you remember batteries that didn’t the same capacity or longevity if you didn’t fully discharge them or fully charge them.Public understanding of battery technology and capability today is the biggest barrier to wider adoption of electric vehicles.We have cleared the technology hurdles, but not the perception issues.

Historically, the energy storage system limited the use of electric vehicles because battery life had been a significant factor.It affects range, recharging time, and cost.Many considerations also must be addressed when selecting a battery to power an electrical vehicle, primarily power density, energy density, weight, volume, cycle life, and cost. Operating temperature range, safety, environmental impact/material recycling, and maintenance play a role as well.

It’s a very complex system. Weight and volume can affect the range and efficiency of the total system. Environmental concerns have fostered the development of electrical vehicles, so the ability to recycle or safely dispose of batteries themselves should be a strong consideration.

Finding The Right Mix

Over the past few decades, battery content has changed. Until the mid-1990s, most electric vehicles used batteries containing lead acid, although some used nickel cadmium.Most commercial hybrid-electric vehicles in service today use nickel-metal-hydride (NiMH) batteries, but some are transitioning to lithium-ion (Li-ion).

With the Tesla Roadster or high-end Model S, users can travel more than 200 miles per charge on its Li-ion batteries. GM’s Chevy Volt plug-in hybrid electric vehicle (HEV) and the Nissan Leaf (BEV) also use a version of Li-ion batteries. Lithium-based technologies and Li-ion batteries are proving to be good options for PHEVs and BEVs.

Li-ion batteries are appealing because they can output high energy and power per unit of battery mass. This means they are light and smaller than rechargeable lead-acid batteries. Compared to lead-acid and NiMH batteries, Li-ion batteries are very energy-efficient, boast a long cycle life, and have none of the memory effects that have been associated with rechargeable batteries.

Unfortunately, Li-ion batteries are the most expensive option for PHEVs and BEVs right now and contain toxic electrolytes that make disposal a high concern.In the future, lithium air technology may become a considered option, as it holds as much as five or 10 times as much energy as Li-ion batteries, and this high energy density increases their vehicle range.

Another option is lithium-iron-phosphate, lithium-ferrophosphate (LPF), or iron-phosphate (FE) batteries.These batteries have about a 15% lower energy density, but offer longer cycle life, great power density, and a more thermally and environmentally stable chemistry than Li-ion batteries, which makes them safer.

Small Things Add Up

The development of cell-phone technology and the evolution of mobile devices have certainly aided advances in battery technology for electric vehicles. We have been able to leverage manufacturing scale and components and even driven down costs, for example.

However, the cost of a battery in a car is amplified because we’re not just talking about a single cell, which you have in your mobile phone. We’re talking about thousands of cells strung together and the costs of labor and materials to connect those cells together.Tesla’s Roadster has more than 8000 cells.Each cell was independently monitored for voltage, temperature, and other specifications. That means overhead for electronics.

Monitoring is so important because each of those cells is a very high-energy and potentially volatile device in adverse conditions.You can only pack so much energy into a device like that, and risks are inevitable.When these batteries go into catastrophic failure, they “rapidly dissemble.” They don’t just get spit out. They can do very bad things. That’s why you see really big headlines for battery recalls for devices such as laptops.

When you use a high-energy-density technology in vehicles and you’ve got 8000 cells strung together, you have to include a lot of safety elements that increase the cost of that system.Let’s be clear: BEVs are safe. They are as safe to drive as any gasoline-powered vehicles.

Iron-phosphate batteries are fire-safe, for example, even if they are slightly less energy dense.Iron-phosphate batteries can be cycled more than 7000 times. That means they can be fully discharged every day for more than 20 years of life!We have batteries today that will outlive the vehicles they are in. There is no longer a barrier of longevity or calendar life for these batteries.

A Battery With Another Name

Fuel cells have a lengthy history as well. Their genesis goes back as far as 1801 when Humphry Davy first demonstrated the principle of what became fuel cells.William Grove invented the first fuel or “gas battery” in 1839. Francis Bacon demonstrated a 5-kW alkaline fuel cell in 1959. NASA employed fuel cells in space missions in the 1960s. By 2007, fuel cells started being sold commercially as auxiliary power units and for stationary backup power. Honda began leasing the FCX Clarity fuel-cell electric vehicle in 2008.

Whether placed in a car or a bus, fuel cells run on hydrogen, which is pumped into the tank of the vehicle like gasoline. The hydrogen is then fed into the fuel cell, where it is electrochemically converted into electricity. But unlike a gasoline-powered vehicle, there is no combustion and no emissions other than water vapor. The electricity that is generated powers the vehicle.

Just as automakers around the world are developing BEVs, they are looking at the viability of hydrogen-powered fuel-cell vehicles. Fuel cells are also seeing a great deal of use within public transportation. BC Transit in Vancouver, Canada, has been running a five-year demonstration program slated to run until 2014 to test the operational viability of fuel cells in buses, making it the world’s largest hydrogen fuel-cell fleet operating in a single location.

Meanwhile, the Federal Transit Administration, through its National Fuel Cell Bus Program, recently awarded $5.9 million to the Center for Transportation and the Environment (CTE) to manage several applied research projects from around the country, including full-scale fuel-cell bus demonstrations. CTE will coordinate a new vehicle demonstration with Tompkins Consolidated Area Transit and Cornell University in Ithaca, N.Y. CTE will also manage the extension of existing demonstration projects at Alameda-Contra Costa Transit District in Oakland, Calif., and Birmingham Jefferson County Transit Authority in Birmingham, Ala.

Despite these and other pilot projects, fuel cells used in vehicles face their own set of challenges, including issues related to cost, manufacturing, robustness, hydrogen production, safety/fuel volatility (remember the Hindenburg?), and the hydrogen infrastructure.

A Different Kind Of Hybrid Vehicle

One of the main challenges for mass adoption of electric vehicles by consumers is range, which the infrastructure could address. Charging stations could eventually become as common as gas stations along every highway in America.Every motel would have a charging station, making a cross-country family road trip in an electric vehicle a viable vacation.

The beauty of the all-electric vehicle, besides being environmentally friendly, is its simplicity. Building a vehicle that includes both battery technology and fuel-cell technology would be an integration challenge from both an engineering and manufacturing perspective.

An all-electric vehicle has 30% fewer parts than a standard internal combustion engine. It’s also more reliable. It requires less maintenance in part as well because there are fewer fluids to change out. Occasionally, though, you will have to change the windshield wiper blades and tires.

Fuel cells could be a complementary technology, though they add complexity and produce some waste. If and when they achieve commercial viability, incorporating fuel-cell technology within an electric vehicle could make for a marvelous range extender.In such a hybrid vehicle, the battery would be a storage device, while the fuel cell would be the mini-generator. Vehicles that take the opposite approach, with a small battery and a large fuel cell, would not likely make sense except in niche markets because of these challenges.

Long Live The Battery!

Regardless of what type of rechargeable battery ultimately becomes the standard for electric vehicles, longevity has been overcome.We have battery technology that will last 30 years, outliving any car. Some vehicles on the market today can go 230 miles on a single overnight charge—approximately five hours in an owner’s garage—and be able to drive that distance the next day.

But perceptions of drivers must be managed and shifted. In the same way mobile phone technology has contributed to the development of rechargeable batteries in electric vehicles, they can be used to change attitudes of the general public.

Take wired landline phones for example. You can pick them up any time of day, any time of the week, and you can talk as long as you want. You don’t think about power. Even cordless phones are returned to a charging station when they aren’t in use and easily last as long as most conversations. And you don’t worry about being tethered.

When the first mobile phones were introduced, they barely offered 20 minutes of talk time, but eventually the paradigm shifted and so did people’s expectations.We don’t expect a cell phone to last all week on a single charge, but we still expect a vehicle to last all week after we have filled the tank with gas.

The difference is that we are okay with plugging in our phone to charge it whenever the opportunity comes up—not just overnight, but while we are at work, at lunch, traveling, or home making dinner, for instance. We’ve come to an understanding that we have to charge it whenever we have down time.We don’t expect it to last two days in talk time.We don’t expect it to last a week in standby time, and that’s because we have changed our thinking.

This shift is happening in some parts of the world. There are now 650 to 1000 electric taxis running in Shenzhen, China, and all of them only go 187 miles on a single electric charge with air conditioning running.However, they are driving totals of 300 to 400 miles per day because they are opportunity charging.

When the cars start out in the morning, they are fully charged. But as with taxis in most jurisdictions around the world such as London or New York, they are idle about 40% of the time.When taxi drivers stop to go to the bathroom, they plug in. When they go for lunch breaks, they plug in. When they are sitting in the taxi queue, they are plugged in.

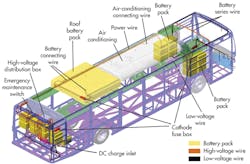

A change in thinking occurred there to revolutionize a high-utility, long-range application. It also can happen in North America, if not immediately for consumers, then certainly for high-utility public transportation.There is no two-shift taxi operation or bus route in the United States that couldn’t be covered with an electric taxi or bus with opportunity charging (see the figure).

This same thinking needs to happen before electric vehicles see wider adoption.The battery technology is there.We have to shift attitudes and our thinking so drivers are as comfortable “opportunity charging” their vehicles as they are their “untethered” phones, while at the same time providing the infrastructure to do so.

We saw a revolution from land lines to mobile phones occur within a decade.This same new “battery-based” energy revolution will occur in the transition away from gasoline to electrified transportation.

This file type includes high resolution graphics and schematics when applicable.

About the Author

Micheal Austin

Vice President

Micheal Austin is vice president at BYD America and a founding board member of the IEEE Transportation Electrification Initiative. He received his degree in design engineering as well as a master’s degree in mechanical engineering from Brigham Young University. He worked for Motorola for 15 years in functions including ODM director for the Mobile Devices Business and global energy commodity manager. He was selected as Motorola’s Distinguished Innovator (with 22 U.S. patents) in 1999.