Designers often use a current shunt to measure low current being sourced out of their power supply since many of today’s power supplies do not offer adequate accuracy from their built-in measurement systems. Using a shunt is simple. Just select a shunt resistor of a known resistance, measure the voltage drop across the shunt, and use Ohm’s law to calculate the current.

In practice, this means you must accurately know the resistance of the shunt, consider any drift in the resistance value, and be careful about sizing the shunt so you don’t have too much burden voltage (the voltage drop across the shunt that takes away from the final voltage that appears at the device under test, or DUT).

Related Articles

- Expect More Power In PXI, But Watch Out

- Why Can't You Put Electronic Loads In Series To Get More Voltage?

- Capacitors Create Challenges When Modulating DC Power

The Alternatives

For static current or current that changes over a small range (10:1), this method works fine. But for dynamic currents, using a shunt becomes more challenging. If you size the shunt for the low current, the burden voltage becomes too big at high current. If you size the shunt for high current, you may not get enough measureable voltage at low current for an accurate current measurement.

This may force you to consider using multiple shunts, which can work well if you can control when the current is flowing. If you can control your DUT and your test sequence so you know you are drawing high current for one test and low current for another, then you can use relays to switch between the shunts to achieve wide dynamic range of measurement. But switching shunts could take many milliseconds and adds complexity, so it may not be a suitable answer for high-throughput automated test equipment (ATE).

This file type includes high resolution graphics and schematics when applicable.

You may want to try using one shunt to cover the whole dynamic range of current, though measuring both high and low current from the same shunt offers its own challenges. As the dynamic range of current to be measured gets larger, to minimize burden voltage at high current, you will be forced to use a smaller shunt with a smaller voltage drop at low current.

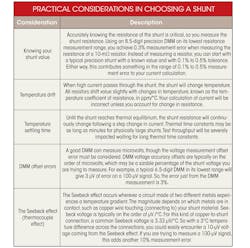

Let’s say your DUT requires 10 A at full operation and 10 mA in standby mode. This is a 1000:1 dynamic range of current. If you select a 10-mΩ shunt to keep your burden voltage low, you will have a 100-mV drop at 10 A and a 100-µV drop at 10 mA. You might think this should be easy to get an accurate measurement, but there are several practical considerations (see the table). So, it isn’t so easy to accurately measure low current using a milliohm shunt, as there are many factors to consider.

Another approach is to select a power supply that has the built-in current measurement that you need. In this case, the test equipment vendor has fully engineered the solution, accounting for the considerations in the table, resulting in traceable, documented specifications. Such a power supply will be more expensive than a less capable supply plus a current shunt. But if accurately measuring current is your objective, the extra cost of the power supply reduces complexity and significantly raises test confidence and test throughput.

The Agilent Advanced Power System N7900 Series Dynamic DC Power Supply is specifically designed for measuring wide dynamic current (see the figure). It offers fast, accurate measurement of a 5000:1 dynamic range of current, such as measuring from milliamps to dozens of amps.

Bob Zollo is a product planner with the Power and Energy Division, Electronic Measurements Group, at Agilent Technologies. He is responsible for creating Agilent’s power products roadmap by researching customer and industry trends and developing product plans to meet emerging customer needs. He holds a degree in electrical engineering from Stevens Institute of Technology in Hoboken, N.J. He can be reached at [email protected].

About the Author

Bob Zollo

Solution Architect for Battery Testing, Electronic Industrial Solutions Group

Bob Zollo is solution architect for battery testing for energy and automotive solutions in the Electronic Industrial Solutions Group of Keysight Technologies. Bob has been with Keysight since 1984 and holds a degree in electrical engineering from Stevens Institute of Technology, Hoboken, N.J. He can be contacted at [email protected].