Installing Open-Frame and U-Channel AC-DC Power Supplies

Download this article in PDF format.

Engineers must be wary of safety, electromagnetic-compatibility, and thermal-management factors when installing open-frame and U-channel power supplies.

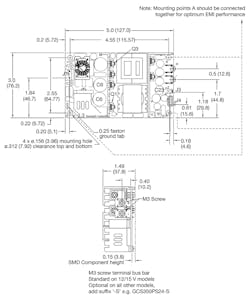

Typically, power supplies are supplied in what is known by the industry as an open-frame format. Open frame generally describes a PCB-only-construction, component power supply designed to be installed into an end-equipment application that provides the enclosure for the entire product (Fig. 1).

1. Power supplies are often provided in an open frame, as shown, relying on the end-application to provide a suitable enclosure to provide additional safety and EMC protection for the PCB.

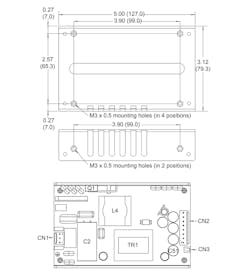

Another common format for power supplies for integration into end equipment is the U channel, where the power-supply PCB is installed in a U-shaped, usually aluminum, chassis that’s often used as a part of the thermal management of the power semiconductors (Fig. 2). It also provides multiple fixing options for the equipment manufacturer to install the supply into the final assembly.

2. The alternative to an open-frame power supply is the U channel, supplied either without a cover (a) or with one (b). This type of enclosure can provide some thermal conductivity, as well as additional EMC protection and increased mounting options.

There are several considerations when installing open-frame and U-channel power supplies. Principally, they’re related to safety, electromagnetic compatibility (EMC), and thermal management, all of which are discussed in this article.

Another important consideration is the detailed specification of the power supply, especially with regard temperature and input voltage derating, when compared to the datasheet headline power rating. The best products maintain the rated power to 50°C ambient temperature and down to 90-V ac input. Some products advertise a headline power rating with derating of up to 20% at low line and derate the available power at ambient temperatures as low as 40°C, which may make these products unsuitable for the end application.

Safety

When mounting an open-frame power supply into the equipment enclosure, it’s necessary to observe the required creepage and clearance distances to the equipment enclosure to all faces of the supply (Fig. 3). In a class I system, this will mean ensuring 3 or 4 mm between any earthed metal part and any primary part of the power supply, depending on whether the end application is industrial or medical. This may necessitate the use of insulators around the power-supply assembly.

3. By consulting the mechanical drawing of an open-frame power supply, engineers can assess the best way to mount the supply in the end-application and determine where to attach the ground connections needed to comply with safety regulations. This is often made using one of the mounting holes, but it may be necessary to connect several earth points, which can have implications.

When employing a class I power supply, the safety ground connection to the power supply is an integral part of the electrical safety system and must be securely connected to the equipment safety ground. This connection is generally made available via one of the mounting holes, via the AC input connector, or via a FASTON-style tab on the power-supply PCB. There’s likely to be more than one earth connection to the assembly required, which affects the electrical emissions and susceptibility performance (discussed later).

When employing a class II power supply, the creepage and clearance distances may be required to be larger in metal enclosures. However, the equipment enclosure often is non-conductive with these units.

U-channel construction eases the issues surrounding safety, because the U-channel chassis is connected to the supply’s safety ground and can be bonded directly to the equipment enclosure along with the power-supply safety ground connection (Fig. 4). The design caters to the requirements for safety clearances between the PCB and the surrounding U channel. However, the ends of the U channel and the top face of the assembly are usually still open; thus, care must be taken in these areas to ensure adequate creepage and clearances distances are maintained.

4. Mounting points in a U-chassis power supply, as shown in this mechanical drawing, can also provide multiple grounding points. This simplifies installation and can improve EMC performance.

U-channel construction has the additional benefits of ease of handling and ease of installation. The U chassis provides a more rugged construction and incorporates threaded mounting holes for use by the installer, reducing the mounting hardware to a simple screw fixing. Care must be taken to observe any maximum screw-insertion penetration depth to maintain safety creepage and clearance distances.

Another U-channel construction benefit is the potential for additional cooling of the power components by conduction cooling to the equipment enclosure. This reduces both the temperature of the bonded components and, consequently, the general temperature within the U channel construction.

Both open-frame and U-channel power supplies include one, or sometimes two in the case of products designed for medical-equipment applications, input fuses. Such fuses are also integral to the overall product safety system design and protect against fire hazard in the event of catastrophic failure. This fuse is usually permanently installed in the power supply and not designed for replacement—the only reason for clearing of the fuse is due to failure of the power-supply assembly.

Both constructions require input cabling, but the end equipment also needs additional fusing to protect against potential fire hazard issues created by the incorporation of connectors, indicators, switches, and the cabling itself.

Output cables must be sized to accommodate the maximum power capability of the power supply. This includes the maximum tolerances for its overload protection specification to ensure safe operation in the event of a fault in the equipment.

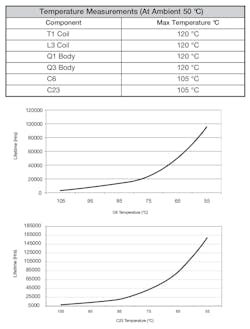

There are also thermal considerations, as some safety-critical components have a maximum temperature rating. This is discussed in more detail under thermal management.

Electromagnetic Compatibility (EMC)

Open-frame power supplies normally require two and sometimes three mounting points to be connected to ground. As discussed above, in a class I system, one of these connections—located on the input side of the assembly—is typically required for safety ground.

Such a connection will also connect the line to ground and neutral to ground common-mode filter capacitors, also known as Y capacitors. These Y capacitors work in conjunction with the common-mode inductors within the power-supply assembly to attenuate noise associated with rapid changes in voltage in the supply’s power stage. The other or others are usually on the secondary side and connect the output common-mode filter capacitor(s) to ground. The differential element of the filter, which is designed to attenuate the noise associated with rapid changes in current, is contained within the supply in the line and neutral connections.

The output common-mode capacitor is integral to the EMC performance of the power supply and must be connected for optimum EMC performance. This is rarely an issue if the equipment uses a metal enclosure. In plastic enclosures, either in class I or class II configurations, it’s necessary to make other provisions to connect these points together to ensure EMC compliance. The points that require connection to ground or together are usually identified in the power-supply datasheet as in the following example.

The optimal way to connect these points is by mounting the open-frame supply on a metal plate. It needn’t be connected to anything else, but provides a low impedance path with low parasitic elements for the filter capacitors to be connected. When this type of mounting is impractical, other methods must be employed to connect these mounting points, such as a multi-strand cable.

In a U-channel construction, all ground connections are made within the U-channel enclosure, simplifying the installation of power supply from an EMC perspective. Good electrical bonding from the U-channel chassis to the equipment enclosure via multiple fixing points is also beneficial, minimizing parasitic elements.

In both cases, the input and output cables should be kept well apart and avoid close proximity to the open assembly. This is to avoid potential issues with radiation from the switching components and magnetic assemblies within the power supply being induced into the system, creating potential conducted and radiated emissions issues for the end equipment.

Thermal Management

Open-frame power supplies may have a power rating when convection-cooled, force-air-cooled, or both. In the case of U-channel supplies, there may also be a conduction-cooled rating utilizing the equipment enclosure or external heatsinking for further cooling of the assembly.

The mounting position, orientation, available surrounding space, applied load, and surrounding parts, along with any system air cooling, are unique to each application. It’s important to check the operating temperature of key components within the power-supply assembly once installed to ensure that the safety-critical components don’t exceed their maximum ratings as specified in the safety-approval reports, and that it doesn’t impair the reliability and service life of the supply.

5. When selecting a power supply, it’s important to observe the maximum rated operating temperature and compare that to the thermal performance of the application. It may highlight the best location for the power supply or indicate that additional cooling is required.

Datasheets for both open-frame and U-channel power supplies destined for integration into end equipment commonly identify the key safety components and their maximum temperature ratings—these vary from one supply to another depending on the class of insulation system employed (Fig. 5). In addition, they typically provide an estimated service life curve based on the temperature of key electrolytic capacitors, which are the only parts with a wear-out mechanism within the power supply.

Service life predictions are based on the electrolytic capacitor design lifetime at its maximum temperature rating and the average temperature experienced in the end application over its mission profile. Clearly the maximum temperature rating can’t be exceeded under any circumstances or extremes of operation.

All electrolytic capacitor lifetime calculations are based on the Arrhenius equation, where the rate of reaction halves and hence the lifetime doubles for every 10°C reduction in temperature. Thus, it’s a critical element in the service life or service interval of the entire end application.

Lifetime calculations undertaken by the power-supply manufacturer will include elements based on the applied ripple current. However, this is impractical in the finished power-supply assembly. Therefore, a good indication of service life can be determined by measurement of the component case temperature and application of the Arrhenius equation to the specified temperature and design lifetime.

Gary Bocock, Technical Director at XP Power, is a qualified electronics engineer and Member of the Institution of Engineering and Technology (MIET). He has worked in the power-supply industry for 30 years in design, development, applications, and management roles. He has been with XP for over 20 years and has held a variety of engineering and management jobs.

About the Author

Gary Bocock

Technical Director, XP Power

Gary is a qualified electronics engineer and Member of the Institution of Engineering and Technology (MIET). He has worked in the power-supply industry for 30 years in design, development, applications, and management roles. He has been with XP for over 20 years and has held a variety of engineering and management jobs, culminating in his present position as Technical Director.