Most electronic devices exhibit a pulsing behavior, where peak power is much higher than standby power. This includes mobile (i.e., battery-operated) devices. Some common examples of battery-operated devices with pulsing behavior include:

- Wireless sensors that periodically transmit information across a long distance

- Electric hand tools and toys with actuating motors

- Bluetooth audio speakers with high dynamic range

- Medical-device pumps with backup-battery supplies

A major design goal for a mobile device is to maximize battery runtime (no one wants to face the ire directed at Apple over their phones’ battery problems). Typically, the largest design efforts to achieve this involve minimizing standby power through careful selection and implementation of components with low quiescent power. An example of products that do this well are biometric sensors powered by energy harvesting. However, there should be an equal emphasis on designing for peak power, because an inability to support these peaks will result in premature battery replacement.

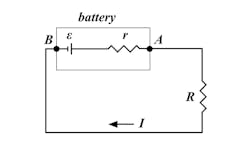

As a battery loses charge, it diminishes its ability to deliver peak power. This is due to a property of batteries known as internal resistance. This resistance is modeled in series with the battery output, and is a function of the battery’s size, chemistry, age, temperature, and state of charge. Figure 1 shows an equivalent circuit of a battery driving a simple load, with internal resistance shown as parameter ‘r’.

1. Here’s an equivalent circuit of a battery driving a simple load, with internal resistance shown as parameter ‘r’.

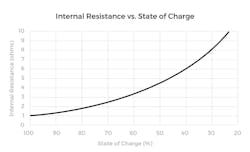

As the internal resistance increases, more power is dissipated across it and less is available for the load. Eventually, the internal resistance becomes so large that the battery will not be able to deliver sufficient peak power, especially in a pulsing application. A significant factor of internal resistance is state of charge—as a battery becomes depleted, it increases internal resistance. This behavior is shown in Figure 2.

2. A significant factor of internal resistance is state of charge. As a battery becomes depleted, its internal resistance increases.

A pulsing application requires low internal resistance for proper function. For example, consider a scenario where a 3-V battery needs to periodically deliver 0.5 A to a pulsed load such as a smoke alarm. From analysis of Fig. 1, if the battery’s internal resistance is 3 Ω, then the voltage available for the motor is 3 – (3 × 0.5) = 1.5 V, and the motor would not run well at all. If the battery matched the behavior shown in Fig. 2, it would reach this bad state (internal resistance = 3 Ω) when it still had 60% capacity left and would already need to be replaced! This is an example of peak power limiting battery runtime. Ideally, a battery should be usable across its entire range of charge.

Fortunately, several design techniques can prevent this from happening:

1. Peak power pulses can be reduced by introducing large capacitors near the load circuit, by spreading out discharge energy over time. This ability is limited by the size and cost of the capacitors that the device can accommodate.

2. Peak power pulses can also be reduced by slowly ramping up (e.g., soft starting) the load. This is limited by the dynamic requirements of the circuit, and how slowly it can ramp up while still functioning well.

3. Series resistance within the circuit can be lowered through careful design of connectors, wiring, and PCB layout. For very high peak power devices like motors, a small reduction of 100 mΩ can have a noticeable effect. One pro tip is to avoid using battery “spring” connectors like those shown in Figure 3 for high-power applications. These connectors can have hundreds of milliohms of series resistance and thus have a detrimental impact on applications with motors.

4. Peak power may be reduced by careful selection of application components. For example, try to choose wireless ICs with lower current draw during transmit pulses, and select motors with lower startup current.

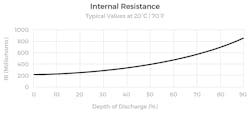

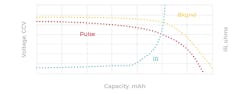

5. Finally, choose the right battery for the application. Careful consideration should be paid to internal resistance over the life of the product, to prevent premature battery replacement. Good examples of variation are shown in Figures 4 and 5, which indicate significant differences in internal resistance for coin-cell and alkaline batteries.

3. Avoid battery spring connectors, like the ones pictured here, in high-power applications.

The HelmetFit product, a wireless air pump designed at Bresslergroup, employed several of these techniques to optimize performance and battery life. Careful selection of the internal pump (technique #4) and battery (technique #5) were combined with a soft-start algorithm (technique #2) to maximize battery life while delivering peak performance in all applications.

4. There are significant differences in internal resistance for coin-cell and alkaline batteries. Compare this chart showing alkaline AAA battery internal resistance (IR) vs. depth of discharge to that in Fig. 5. (Source: Radio Shack)

5. Choosing the right battery for the application is key to preventing premature battery replacement. This chart shows coin-cell 2450 battery internal resistance (IR) vs. depth of discharge. (Source: Energizer)

Internal resistance can prevent using the entire battery capacity in pulsing applications. Consideration must be given to peak power requirements, through prudent design and battery selection, to significantly boost battery runtime.

About the Author

Kevin Murphy

Senior Principal Electrical Engineer, Bresslergroup

Kevin Murphy is a Senior Principal Electrical Engineer at Bresslergroup, where he works on electronics hardware, and firmware design in categories ranging from consumer products, including IoT, to medical devices. He has more than 20 years of experience in the medical-device and consumer-electronics fields. Kevin earned a BS in Electrical Engineering from Drexel University and an MEng in Electrical Engineering from Princeton. He considers reliability to be every product's legacy.

Kevin wanted to be an electrical engineer when he fixed his first remote-controlled truck at age eight. He considers reliability to be every product’s legacy. “In the long run,” he says, “nobody remembers the pains it took to create a product, but users appreciate it if it works every time.”