Flyback-Topology DC Controller Drops Need for Optical Isolator

Numerous applications can’t operate in low-voltage ranges due to the physical reality of their situation. For these installations, a converter such as the Analog Devices LT8316 600 VIN isolated flyback controller may offer a solution.

Working in conjunction with peripheral components and a flyback transformer, this IC accepts a 16- to 600-V input and delivers an isolated output of up to 100 W. It does so without a need for an optoisolator, which can bring in extra design issues such as the need for extra components (their size cost), along with performance concerns related to limited dynamic response, nonlinearity, unit-to-unit variation, and aging over its life.

The controller works by sampling (in the analog domain) the delivered output voltage as observed via a tertiary winding on the special flyback transformer. It implements a switched-mode, quasi-resonant form of boundary-mode operation to improve load regulation, reduce transformer size, and maintain high efficiency.

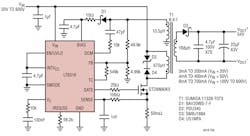

In a flyback design, the single magnetic component—that three-winding transformer—is used not only for voltage step-up/step-down, but also functions as a coupled inductor, thus merging three the key functions of energy storage, energy transfer, and isolation. The LT8316 supports low-cost designs such as the 94% efficient, 20- to 600-V input, 54-V output isolated supply shown in the figure. The datasheet provides other designs, as well.

This flyback-topology power converter based on the LT8316 provides an isolated 54-V dc output from an input between 20 V and 600 V, with 94% efficiency. (Source: Analog Devices)

Updating a Classic

If the flyback-converter concept sounds new, it’s not. It was developed the 1930s and matured in the 1940s and 1950s when it was used in nearly every TV to develop the high voltage (~20 kV) needed by the CRT display. The flyback approach features low parts count and inherent input/output isolation, critical in those mass-market applications, Modern versions often use an optoisolator, but the LT8316 is a much-updated semiconductor version of the classic design. It, too, uses that third winding on the transformer for the feedback signal. (The References below provide additional insight into flyback topology, operation, and construction.)

The LT8316 controller goes beyond those classic CRT-based flyback designs, with constant-current and constant-voltage regulation; in normal operation, the current source turns off and the device gets its power from that third transformer winding to minimize standby-power dissipation. Quiescent current is just 75 μA, while the device also provides low-ripple operation during light-load periods. Other features include programmable current limit and soft-start to minimize transients and component stress.

The flyback transformer isn’t just a simple turns-ratio magnetic component, so the datasheet explains in detail how to determine its specifics and size it for the voltage, current, and power requirements. (In most projects, of course, specific transformer selection has subtleties and is rarely as simple as their underlying basic turns-ratio principle and power rating implies.)

Since the transformer specification and design is likely the most critical part for successfully implementing any flyback design, Analog Devices worked with several leading magnetic-component manufacturers to produce pre-designed flyback transformers for use with the LT8316. These are called out on the datasheet for different voltage combinations along with the vendors and their model numbers.

The LT8316 is housed in a modified, thermally enhanced 20-pin TSSOP package, but with four pins removed to meet high-voltage spacing mandates. Pricing starts at $2.18 each (1000-piece lots).

References

Texas Instruments, “Understanding the Basics of a Flyback Converter”

Electrical Engineering Stack Exchange, “How does a CRT television flyback really operate”

Autodesk Instructables, “2n3055 Flyback Transformer Driver for Beginners”

Robert Gawron, “High voltage supply (10-30kV) made from CRT television flyback transformer”

Electronc Repair Guide, ”What Is Flyback Transformer?”

Wikipedia, “Flyback transformer”

About the Author

Bill Schweber

Contributing Editor

Bill Schweber is an electronics engineer who has written three textbooks on electronic communications systems, as well as hundreds of technical articles, opinion columns, and product features. In past roles, he worked as a technical website manager for multiple topic-specific sites for EE Times, as well as both the Executive Editor and Analog Editor at EDN.

At Analog Devices Inc., Bill was in marketing communications (public relations). As a result, he has been on both sides of the technical PR function, presenting company products, stories, and messages to the media and also as the recipient of these.

Prior to the MarCom role at Analog, Bill was associate editor of their respected technical journal and worked in their product marketing and applications engineering groups. Before those roles, he was at Instron Corp., doing hands-on analog- and power-circuit design and systems integration for materials-testing machine controls.

Bill has an MSEE (Univ. of Mass) and BSEE (Columbia Univ.), is a Registered Professional Engineer, and holds an Advanced Class amateur radio license. He has also planned, written, and presented online courses on a variety of engineering topics, including MOSFET basics, ADC selection, and driving LEDs.