One of the many challenges in determining how long any battery will be useful is that it’s difficult to make that assessment early in its use cycle. That situation may change due to a project carried out by a collaborative Stanford/MIT team working under the auspices of Center for Data-Driven Design of Batteries. The academic-industrial collaboration includes the Toyota Research Institute and has a goal of integrating theory, experiments, and data science.

They used AI/machine-learning sophistication and algorithms to develop models that accurately predict long-term battery life by using data collected from charge-discharge cycles that’s been measured only in the early stages of a battery’s life. “The standard way to test new battery designs is to charge and discharge the cells until they fail. Since batteries have a long lifetime, this process can take many months and even years,” said co-lead author Peter Attia, Stanford doctoral candidate in materials science and engineering. “It’s an expensive bottleneck in battery research.”

The objective was to accurately predict the useful life of lithium-ion batteries (with lithium-iron-phosphate cathode and graphite anode) solely derived on early-cycle data acquired long before their capacities being to decline. To generate the training data set and develop the model, they cyclically charged/discharged 124 commercial batteries until each one reached the end of its useful life (which they defined as capacity loss of 20%). The batteries from A123 Systems, with nominal capacity of 1.1 Ahr and a nominal voltage of 3.3 V, were cycled in horizontal cylindrical fixtures in a forced-convection temperature chamber a 30°C.

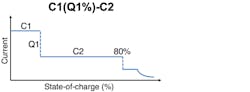

1. Beyond 80% SOC, all cells are charged galvanostatically at 1C to 3.6 V and then charged potentiostatically at 3.6 V. The upper value for each current is limited to the manufacturer’s upper voltage limit of 3.6 V. (Source: Stanford University)

They used two fast-charge modes but with identical discharge conditions to vary the cycle lives of the batteries before each reached the end of its life (Fig. 1). The charging mode was “C1(Q1)-C2,” in which C1 and C2 are the first and second constant-current steps, respectively, and Q1 is the state-of-charge (SOC, %) at which the currents switch. The second current step ends at 80% SOC, after which the cells charge at 1C CC-CV. All batteries were discharged at 4C (C is a cell’s capacity). Internal resistance measurements were obtained during charging at 80% SOC by averaging 10 pulses of ±3.6C with a pulse width of 30 ms or 33 ms. The test batteries endured between 150 to 2,300 charge/discharge cycles.

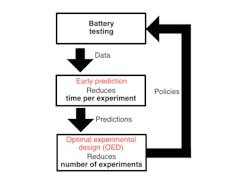

The resultant set of a several hundred million data points was used to train their model and the algorithm. This determined each battery’s state-of-health (SOH) and predicted how many more cycles each would last, primarily using data on voltage declines and a few other factors among the early cycles (Fig. 2). Note that battery SOH is a complex state involving two major characteristics of aging batteries (among other considerations): their progressive loss of storage capacity (called capacity fade); and the increase in internal impedance, which reduces the amount of actual power the battery can deliver to the load.

2. In the closed-loop optimization system, the battery-test batteries’ data goes to an early-prediction model. Those predictions are applied to a Bayesian optimal experimental-design algorithm, which recommends the next policies to be tested. (Source: Stanford University)

The team’s predictions were within 9% of the final number of cycles of battery life. Further, the algorithm was able to categorize batteries as having either long or short life expectancy after just the first five charge/discharge cycles, with these predictions considered to be correct 95% of the time.

“For all of the time and money that gets spent on battery development, progress is still measured in decades,” said study co-author Patrick Herring, a scientist at the Toyota Research Institute. “In this work, we are reducing one of the most time-consuming steps—battery testing—by an order of magnitude.”

The results were reported in their detailed paper published in Nature Energy, “Data-driven prediction of battery cycle life before capacity degradation,” along with comprehensive supplementary material. As an added benefit, the researchers have made the underlying dataset—claimed to be the largest of its kind—publicly available here.

About the Author

Bill Schweber

Contributing Editor

Bill Schweber is an electronics engineer who has written three textbooks on electronic communications systems, as well as hundreds of technical articles, opinion columns, and product features. In past roles, he worked as a technical website manager for multiple topic-specific sites for EE Times, as well as both the Executive Editor and Analog Editor at EDN.

At Analog Devices Inc., Bill was in marketing communications (public relations). As a result, he has been on both sides of the technical PR function, presenting company products, stories, and messages to the media and also as the recipient of these.

Prior to the MarCom role at Analog, Bill was associate editor of their respected technical journal and worked in their product marketing and applications engineering groups. Before those roles, he was at Instron Corp., doing hands-on analog- and power-circuit design and systems integration for materials-testing machine controls.

Bill has an MSEE (Univ. of Mass) and BSEE (Columbia Univ.), is a Registered Professional Engineer, and holds an Advanced Class amateur radio license. He has also planned, written, and presented online courses on a variety of engineering topics, including MOSFET basics, ADC selection, and driving LEDs.