Automotive LDO Handles 40-V Inputs, Delivers Single-Digit Outputs

Cite the need for a DC-DC voltage regulator, and the first and sometimes only option that comes to mind for many designers is the switching regulator. That makes sense, as switchers are well known for their efficiency—a very important feature in many applications—as well as other virtues.

Nonetheless, the reality is that the classic low-dropout regulator (for some reason, always denoted as LDO, without the noun) is often the better choice, especially for loads below about one-half to one amp. Depending on the specifics of the use case and duty cycle, the LDO may have comparable or even better efficiency than the switcher. The numbers prove this, as billions are used every year, with many LDOs called out in new designs, too.

Besides the efficiency situation, there’s no doubt that LDOs offer advantages with respect to their negligible rail noise, ease of use and design-in, and their function as a “no headache/no hassle” solution to the voltage-regulation problem—in the right setting, of course.

LDOs Simply Voltage Regulation

Recognizing this situation, STMicroelectronics introduced the LDH40 and LDQ40 voltage regulators for automotive and industrial applications. These LDOs start up from an input as low as 3.3 V, operate with up to 40 V applied, and have low quiescent current. Their wide input-voltage range allows for connection to a vehicle’s 12-V bus that can reach up to 40-V transient, to provide power for infotainment systems, instrument clusters, and advanced driver-assistance systems (ADAS).

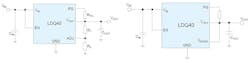

The LDH40 delivers up to 200 mA and is available in a single version with a user-adjustable output voltage from 1.2 to 22 V. The similar 250-mA LDQ40 is available with a 1.2 -to 12-V adjustable output and a choice of 1.8-, 2.5-, 3.3-, and 5.0-V fixed output voltages (Fig. 1). The devices are stabilized with a small ceramic capacitor on the output.

The quiescent current of 2 µA at zero load and a 300-nA logic-controlled shutdown mode help preserve battery energy in always-on standby systems. This minimizes “vampire drain,” which can deplete the battery of a car sitting unused for longer periods of time.

Protection Features and Packaging

The devices have system protection and management features including internal current limiting, thermal protection, soft-start, and output active discharge. There’s an enable pin for shutdown control and a power-good pin for diagnostic monitoring. The LDQ40 devices also have short-circuit protection.

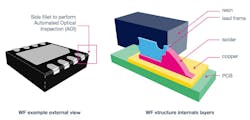

The LDOs are automotive AEC-Q100 qualified and packaged as 2- × 2-mm DFN6L devices with wettable flanks that ease PCB design and facilitate automated optical inspection (Fig. 2).

This packaging addresses a production and manufacturing issue that’s easy to overlook when choosing a part primarily based on its electrical specifications and price to put on the bill of materials (BOM).

Despite their functional simplicity, the two LDOs are supported by 30-page datasheets with the needed tables, specifications, and graphs showing performance across multiple scenarios. Pricing for both automotive products starts from $0.47, while the LDQ40 industrial-grade price starts from $0.40, both in 1,000-unit lots.

About the Author

Bill Schweber

Contributing Editor

Bill Schweber is an electronics engineer who has written three textbooks on electronic communications systems, as well as hundreds of technical articles, opinion columns, and product features. In past roles, he worked as a technical website manager for multiple topic-specific sites for EE Times, as well as both the Executive Editor and Analog Editor at EDN.

At Analog Devices Inc., Bill was in marketing communications (public relations). As a result, he has been on both sides of the technical PR function, presenting company products, stories, and messages to the media and also as the recipient of these.

Prior to the MarCom role at Analog, Bill was associate editor of their respected technical journal and worked in their product marketing and applications engineering groups. Before those roles, he was at Instron Corp., doing hands-on analog- and power-circuit design and systems integration for materials-testing machine controls.

Bill has an MSEE (Univ. of Mass) and BSEE (Columbia Univ.), is a Registered Professional Engineer, and holds an Advanced Class amateur radio license. He has also planned, written, and presented online courses on a variety of engineering topics, including MOSFET basics, ADC selection, and driving LEDs.