This Week in PowerBites: Big Power Innovation Comes in Tiny Packages

This article is part of the This Week in PowerBites Library Series.

What you’ll learn:

- Power innovations aren't limited to the silicon, GaN, and SiC transistors that tend to get all of the attention. Humble diodes, inductors, and relays are also enjoying significant advances in performance and functionality.

- Deployment of grid-scale storage grew 21% between 2022 and 2023, and expected continued growth will enable greater integration of variable renewable-energy resources into the world's power grids.

- Development of specialized high-reliability power devices is helping advance both electric aviation and near-Earth-orbit space applications.

Integrated Actuation Power Solutions Simplify Transition to Electrified Aircraft

A new integrated actuation power solution for electric aviation applications, developed by Microchip Technology, combines companion gate-driver boards with the company’s expansive hybrid-power-drive (HPD) modules in silicon-carbide (SiC) or silicon technology. Power range is 5 to 20 kVA.

The gate-driver boards are designed to be driven with external pulse-width-modulation (PWM) signals based on low-voltage differential signaling (LVDS) compliant with TIA/EIA-644 for low electromagnetic interference (EMI) and good noise immunity.

The board provides differential outputs for telemetry signals like DC bus current, phase current, and solenoid current by taking feedback from shunts present in the HPD module and DC bus voltage. It also provides direct output of two PT1000 temperature sensors available in the module.

The new integrated actuation power solution maintains the same footprint regardless of the power output. The companion gate-driver boards, designed to be integrated with the HPD modules, offer an all-in-one motor drive solution for the electrification of systems such as flight controls, braking, and landing gear.

Microchip’s power solutions are designed to scale based on the requirements of the end application. These range from smaller actuation systems for drones to high-power actuation systems for electric vertical take-off and landing (eVTOL) aircraft, MEA, and all-electric aircraft.

The high-reliability devices are tested to conditions outlined in DO-160, “Environmental Conditions and Test Procedures for Airborne Equipment.” Protection features include shoot-through detection, short-circuit protection, desaturation protection, undervoltage lockout (UVLO), and active Miller clamping.

The isolated gate-driver boards need only a single 15-V DC input for the control and drive circuit. All additional required voltages are generated on the card, significantly reducing the number of system components and simplifying system cabling.

The boards are low-weight, low-profile, and compact solutions to optimize size and power efficiency of actuation systems. The gate drivers are designed to operate throughout the temperature range of −55 to +110°C, which is critical for aviation applications that are often exposed to harsh environments.

The gate-driver boards and accompanying HPD modules are available in production quantities. For additional information, click here or contact Microchip sales.

EV Battery Module Cell-Contacting System Promises Better Manufacturing Efficiency, Reliability, and Sustainability

NOTE: Although most Electronic Design readers don’t need to get this deep into the details of battery design and manufacturing, we’re sharing news about ENNOVI's latest cell contact/interconnect system as an example of the many innovations driving the evolution of batteries at a startlingly rapid pace.

ENNOVI introduced a novel approach to cell-contacting system (CCS) lamination. Historically, the assembly of the CCS on battery cells has relied on cumbersome methods, including molded plastic trays and foams for positioning. While effective for positioning the cells and collectors, these methods introduce unnecessary weight and complexity, especially with increasing module sizes.

Recognizing the limitations of traditional practices, ENNOVI pioneered the use of both hot and cold lamination processes, eliminating the need for these trays or foams. As part of this process, the company qualified polyethylene-terephthalate (PET) insulation foils and adhesives from multiple suppliers by testing them for their bond strength, durability, and environmental impact. In turn, it was able to create a database of recommendations for the most effective material combinations, bypassing the trial-and-error approach that has long been a staple of the industry.

By recommending lamination material combinations, the company offers OEMs and Tier-1 suppliers a streamlined, more adaptable solution.

Till Wagner, Product Manager for Energy Systems at ENNOVI, explained, “Our move towards lamination signifies a major leap in our ability to position collectors with precision, without the mechanical constraints imposed by conventional methods. By curating a database of pre-tested PET foils and adhesives, we not only accelerate CCS design, but also simplify the assembly process, opening up new possibilities for material and energy savings.”

For more information about ENNOVI and its lamination technologies, visit the company's website.

TLVR Inductors Offer Extremely High Current and Fast Response for Data-Driven Apps

The TLVR1005T and TLVR1105T series of multiphase trans-inductor voltage-regulator (TLVR) inductors from Bourns Inc. target applications such as servers, workstations, data centers, storage systems, and desktop computers, as well as graphics cards and various battery-powered systems.

The devices deliver extremely high current capabilities, low inductance, and low DC resistance (DCR). They’re designed to meet the stringent requirements of today’s data-driven application applications requiring the support of power bead inductors that can match their exceptionally high current specifications in the same, if not less, board space.

These products solve a problem that arises with traditional multiphase voltage regulators (VRs) in balancing performance, as high-current output demands require an increase in the duty cycle previously handled via long individual-phase stages.

Their multiphase TLVR architectures offer phase-coupling capabilities that enable extremely fast transient response, which is scalable with CPU, FPGA, and ASIC load requirements. As a result, designers can develop robust systems without sacrificing other critical design parameters such as board space, system efficiency, power density, or bill-of-materials (BOM) costs.

Engineered with a dual-winding structure and clip-type coil, the Bourns Model TLVR1005T and TLVR1105T Series deliver the low inductance and extremely high current capabilities (Irms up to 77 A and Isat up to 160 A) needed in a new generation of multiphase power solutions. The series’ shielded construction maintains low radiation with an inductance range of 70 to 200 nH and an operating temperature range of −40 to +125°C.

For more detailed product information, click here.

Ultra-Low Bias Current/High-Efficiency Zener Diodes Range from 1.8 to 39 V DC

Taiwan Semiconductor unveiled a new series of Zener diodes that provide regulated voltages from 1.8 to 39 V DC, all with an ultra-low bias current (IZT) of 50 µA and maximum power dissipation (PD) of 500 mW. These devices are well-suited for applications where exceptionally low bias current is needed (to extend battery life), essential (for energy harvesting), or desirable (in lighting and IIoT), while still providing uncompromised Zener regulation.

The 39 individual Zener diodes in the series are all packaged in an industry-standard, low-profile, SOD-123 surface-mount package. With their low IZT, these devices are a straightforward upgrade to existing designs (without the need for PCB modifications), as well as for new designs. Pricing is from $0.02, depending on device and quantity; samples are in stock.

Click here for more information and links to complete product specifications and design resources.

Monolithic Automotive Synchronous Buck Converters for Light-Load, Low-Noise, and Isolated Apps

Automotive-qualified, step-down synchronous DC-DC converters developed by STMicroelectronics help save space and ease integration in applications such as body electronics, audio systems, and inverter gate drivers. The A6983 series comprises six non-isolated step-down converters in low-consumption and low-noise configurations, plus the A6983I isolated buck converter. With compensation circuitry on-chip, these highly integrated monolithic devices need only minimal external components.

The non-isolated A6983 converters can supply up to 3-A load current and achieve 88% typical efficiency at full load. The low-consumption variants (A6983C) are optimized for light-load operation, with high efficiency and low output ripple, to minimize drain on the vehicle battery in applications that remain active when parked.

The low-noise A6983N variants operate with constant switching frequency and minimize output ripple across the load range for optimum performance in applications such as audio-system power supplies. Both types offer a choice of 3.3 V, 5.0 V, and adjustable output voltage from 0.85 V to VIN.

The A6983I is a 10-W iso-buck converter with primary-side regulation that eliminates the need for an optocoupler. Targeted for use as an isolated gate driver for IGBTs or silicon-carbide (SiC) MOSFETs in traction inverters and on-board chargers (OBCs), this converter accurately adjusts the primary output voltage. The transformer turns ratio determines the secondary voltage.

All isolated and non-isolated variants have a low quiescent operating current of 25 µA and a power-saving shutdown mode that draws less than 2µA. The input-voltage range from 3.5 to 38 V, and load-dump tolerance up to 40 V, prevent disruption due to transients on the main supply bus.

The converters are offered in a 3- × 3-mm QFN16 package. Pricing starts at $1.75 for the A6983 and $1.81 for the A6983I for orders of 1,000 pieces; free samples of the A6983 and A6983I are available from the ST eStore.

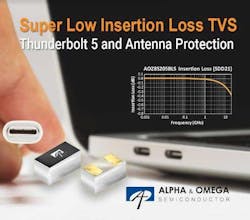

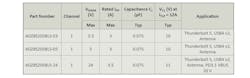

Ultra-Low-Capacitance TVS Diodes Bring ESD Protection to Thunderbolt 5, USB4 v2.0, and High-Speed Line Apps

Alpha and Omega Semiconductor’s AOZ8S205BLS transient-voltage-suppressor (TVS) diodes are designed to meet the increasing electrostatic-discharge (ESD) protection needs in today’s sensitive high-speed line and antenna-based applications.

The ultra-low-capacitance AOZ8S205BLS is engineered using the company’s innovative high-trigger voltage TVS platform, combined with its advanced packaging and 0.075-pF capacitance. It’s well-suited to protect high-speed serial interfaces such as USB4 v2.0 and Thunderbolt 5, which are used in a broad range of electronic systems.

Additional features that boost the protection capabilities of AOZ8S205BLS TVS diodes include lower insertion loss, reverse working voltages (VRWM) of 3.3, 5, and 24 V, and accurate clamping voltage. The AOZ8S205BLS is a single-channel device housed in a 0.6- × 0.3-mm leadless surface-mount device (SMD), which allows it to meet the small footprint requirement of a USB Type-C connector.

The AOZ8S205BLS series is immediately available in production quantities with a lead time of 16 weeks. The unit price in 1,000-piece quantities is $0.066.

Compact Higher-Voltage DC Switching Relay Built for Power and Automotive Systems

The FTR-E1-HC from FCL Components America is a compact, lightweight, 60-A 400-V DC, single-pole PC board switching relay. As one of the smallest in the HVDC 60-A class, it’s a good candidate for a wide range of applications, including electric vehicles, fast charging stations, photovoltaic power generation systems, hybrid construction machinery, and battery systems.

With no specific polarity requirement for the connection of load terminals, and a low power consumption of approximately 1.2 W at rated coil voltage, the FTR-E1-HC eliminates the need to reduce the voltage applied to the coil to the holding voltage. This avoids the cost and space requirements of a holding voltage coil drive circuit.

With a dielectric strength of 5,000 V AC (1 min.) between coil and contacts, and 2,500 V AC (1 min.) between contacts, the relay offers twice the insulation properties of similar relays. Non-polarized contacts enable the FTR-E1-HC to switch reliably between charging and discharging the load. The device, sealed in plastic material, complies with UL flammability standard 94V-0, which stipulates a burning time of ≤10 seconds and afterglow time of ≤30 seconds for each specimen.

The FTR-E1-HC also features FCL Components' Arc Extinguishing Technologies, which use a strategically placed permanent magnet to extend the arc’s path within the same airgap. This ensures a compact, as well as a safe, robust, and affordable solution.

Available immediately, the FTR-E1-HC is lead-free and RoHS compliant. Click here for the datasheet. For additional product information, visit the company’s website.

Rad-Tolerant 50-W DC-DCs Offer High Reliability for New Space Applications

Microchip Technology also recently introduced a new family of radiation-tolerant (RT) LE50-28 isolated DC-DC 50-W power converters, which was created to serve the rapidly growing fleet of low-Earth-orbit (LEO) satellites being used for everything from 5G communication and cube satellites to IoT applications. This LE50-28 series of reliable, cost-effective, and configurable devices is available in nine variants, with single- and triple-outputs ranging from 3.3 to 28 V.

The off-the-shelf family of power converters is designed to meet MIL-STD-461. They have a companion EMI filter and offer customers ease of design to scale and customize by choosing one or three outputs based on the voltage range needed for the end-application. This series has the flexibility to parallel up to four power converters to reach 200 W.

Designed to serve 28-V bus systems, the LE50-28 converters can be integrated with Microchip’s PolarFire FPGAs, microcontrollers, and LX7720-RT motor-control sensor for a complete electrical system solution. The family offers space-grade radiation tolerance with 50-Krad total ionizing dose (TID) and single event effects (SEE) latch-up immunity of 37 MeV·cm2/mg linear energy transfer.

The LE50 series is manufactured with conventional surface-mount and thru-hole components on a printed wiring board. This distinction in the manufacturing process can reduce time-to-market and risks associated with supply-chain disruptions.

Support and Resources

The new converter family is supported by comprehensive analysis and test reports, including worst-case analysis, electrical stress analysis, and reliability analysis.

The company’s other space solutions include FPGAs, power and discrete devices, memory products, communication interfaces, oscillators, microprocessors, and MCUs, offering a broad range of options across qualification levels. For more information, visit Microchip’s space solutions webpage.

Grid-Scale Energy-Storage Boom Accelerates Adoption of Renewable Power

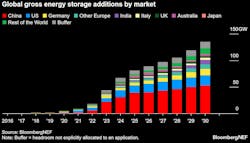

A story issued on April 25, 2024 by Bloomberg NEF, titled "Global Energy Storage Market Records Biggest Jump Yet,” reports that the global energy-storage market almost tripled in 2023, the largest year-on-year gain on record. This remarkable growth was no doubt due in part to the lowest-ever prices, especially in China where turnkey energy-storage system costs in February were 43% lower than a year ago at a record low of $115 per kilowatt-hour for two-hour energy-storage systems.

The report says that last year’s record capacity increase of 45 GWh brings the world's total grid-scale storage capacity to 97 GWh. That the trend is expected to continue for the foreseeable future as scales of economy continue to improve the economics of grid-scale storage.

As a result, the authors anticipate that 2024 will see roughly 137 GWh of new global energy-storage capacity deployed, with the market enjoying an annual growth rate of around 21%. It would bring annual increases in global storage fleet capacity to as much as 442 GWh by 2030

While China is expected to be the largest market for grid-scale storage in the next few years, the report says that the next-largest market will be the U.S., where state targets, utility procurements, and attractive merchant economics in places like Texas drive the market, with substantial uptake also occurring in Europe, Middle East, and Africa.

Besides playing a key role in the integration of grid-scale wind and solar energy, storage technologies represent a significant new opportunity for companies looking to profit from the transition to a sustainable energy economy, and the thousands of engineers who will make it possible.

Read more articles in the This Week in PowerBites Library Series.

About the Author

Lee Goldberg

Contributing Editor

Lee Goldberg is a self-identified “Recovering Engineer,” Maker/Hacker, Green-Tech Maven, Aviator, Gadfly, and Geek Dad. He spent the first 18 years of his career helping design microprocessors, embedded systems, renewable energy applications, and the occasional interplanetary spacecraft. After trading his ‘scope and soldering iron for a keyboard and a second career as a tech journalist, he’s spent the next two decades at several print and online engineering publications.

Lee’s current focus is power electronics, especially the technologies involved with energy efficiency, energy management, and renewable energy. This dovetails with his coverage of sustainable technologies and various environmental and social issues within the engineering community that he began in 1996. Lee also covers 3D printers, open-source hardware, and other Maker/Hacker technologies.

Lee holds a BSEE in Electrical Engineering from Thomas Edison College, and participated in a colloquium on technology, society, and the environment at Goddard College’s Institute for Social Ecology. His book, “Green Electronics/Green Bottom Line - A Commonsense Guide To Environmentally Responsible Engineering and Management,” was published by Newnes Press.

Lee, his wife Catherine, and his daughter Anwyn currently reside in the outskirts of Princeton N.J., where they masquerade as a typical suburban family.

Lee also writes the regular PowerBites series.