Rad-Tolerant DC-DC Converter Supports LEO Satellite Missions

You’re working on the sensor and instrumentation package for your CubeSat or other low-Earth-orbit (LEO) satellite, dealing with the many design complexities, mandates, and packaging constraints for this unique operating environment. Still, there’s one critical function that’s integral to the system yet also somewhat independent—the DC-DC converter that delivers power to the circuitry. It requires a very different set of design skills and know-how for which you and your team don’t have the time or expertise.

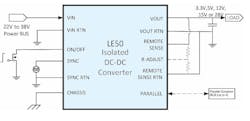

However, concerns about providing this function can be avoided if you consider the LE50-28 family of radiation-tolerant (RT), isolated, DC-DC 50-W power converters from Microchip Technology Inc. (Fig. 1). With its forward-converter topology and a patented magnetic-feedback topology, the LE50-28 is optimized for applications where isolated DC voltage conversion is required in LEO designs.

Flexible, Cost-Effective Converter for LEO Satellites

Microchip maintains that current market offerings are either commercial power converters that aren’t radiation-tolerant and so pose a great risk to the mission life, or expensive radiation-hardened power converters. The LE50 fills the gap between these two by offering a cost-effective radiation-tolerant solution for satellite missions.

These 28-V-input converters are available in nine variants with single- and triple-outputs ranging from 3.3 to 28 V to match end-application requirements (Fig. 2). For additional flexibility, up to four converters can be paralleled to produce up to 200-W output power.

This series provides space-grade radiation tolerance (that’s a less-strict grade than radiation-hardened) with 50-Krad total ionizing dose (TID) and single event effects (SEE) latch-up immunity of 37 MeV·cm2/mg linear energy transfer.

The LE50-28 power converters, all in identical 3 × 2 × 0.5-in. packages, offer a variety of electrical connection and mounting options. The LE50 series is manufactured with conventional surface-mount and through-hole components on a printed wiring board, rather than a module or hybrid arrangement. This distinction in the manufacturing process can reduce time-to-market and risks associated with supply-chain disruptions

The off-the-shelf LE50-28 family of power converters are also designed to meet MIL-STD-461 (“Military Standard: Electromagnetic Interference Characteristics Requirements to Equipment”). As the SA50-28 units do not have a full EMI filter built in, they require an external filter.

Thermally Robust EMI Filter Meets NASA Standards

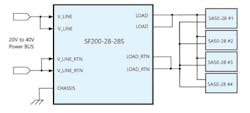

To meet this need, Microchip offers the companion SF200 EMI filter with the same form factor and dimensions as the converters (Fig. 3). The filter weighs just 82 grams and supports up to four SA50-28 converters. As it uses only passive components without any active components, it’s inherently radiation-tolerant.

The available ST-2X3 thermal interface pad provides a thermally conductive interface between converters and the user’s base plate/mounting surface. The pad fills microscopic surface voids without changing phase to maximize heat-transfer capability and is compliant with NASA outgassing standards. It uses a silicone-free, wax-free grease on an aluminum foil substrate, with only 0.004-in. thickness (before compression), offering thermal resistance of just 0.032°C in.2/W (measured at 50 psi).

The converters and accessories, available now, are supported by detailed datasheets with electrical, mechanical, and radiation-tolerance data, and all are downloadable at the product page here.

About the Author

Bill Schweber

Contributing Editor

Bill Schweber is an electronics engineer who has written three textbooks on electronic communications systems, as well as hundreds of technical articles, opinion columns, and product features. In past roles, he worked as a technical website manager for multiple topic-specific sites for EE Times, as well as both the Executive Editor and Analog Editor at EDN.

At Analog Devices Inc., Bill was in marketing communications (public relations). As a result, he has been on both sides of the technical PR function, presenting company products, stories, and messages to the media and also as the recipient of these.

Prior to the MarCom role at Analog, Bill was associate editor of their respected technical journal and worked in their product marketing and applications engineering groups. Before those roles, he was at Instron Corp., doing hands-on analog- and power-circuit design and systems integration for materials-testing machine controls.

Bill has an MSEE (Univ. of Mass) and BSEE (Columbia Univ.), is a Registered Professional Engineer, and holds an Advanced Class amateur radio license. He has also planned, written, and presented online courses on a variety of engineering topics, including MOSFET basics, ADC selection, and driving LEDs.