Laser Ablation Creates Deformable Micro-Supercap for Soft-Wearable Needs

What you’ll learn:

- The challenges of powering skin-attached biosensors.

- Using a laser-ablated micro-supercapacitor to provide a solution.

- The performance yielded by the ablated supercapacitor.

Wearable medical patches offer the potential to monitor and report critical body parameters in real-time, but they need power, of course. One option is to use some sort of backscatter scheme, though this requires relatively close proximity to the primary unit and can only provide limited, sporadic power. Batteries and supercapacitors are also options but have their drawbacks as well. One of them is their physical rigidity and inflexibility, which is at odds with the natural skin motion of humans.

To address this drawback, researchers at Pohang University of Science and Technology (POSTECH/South Korea), and the Korea Institute of Industrial Technology (KITECH), achieved a significant breakthrough in developing a small-scale energy-storage device capable of stretching, twisting, folding, and wrinkling. Recognizing that micro-supercapacitors (MSCs) are a promising candidate for deformable energy storage due to their relatively high power density, rapid charging, and long lifecycle, they looked into the stiffness issue.

How to Fabricate the Flexible, Finely Patterned Electrodes

Fabrication of interdigitated electrode patterns capable of maintaining the energy-storage performance under repeated stretching and twisting is a challenge, because brittle materials like gold (Au) have been commonly used as an electrode. Meanwhile, although eutectic gallium-indium liquid metal (EGaIn) has high conductivity and deformability, it’s extremely difficult to achieve a fine patterning of EGaIn due to its very high surface tension.

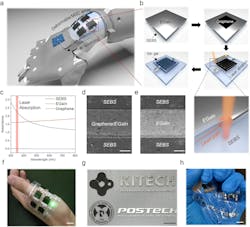

The research team successfully fabricated the fine patterning using laser ablation of both EGaIn and graphene (serving as an active material) layers on a stretchable substrate of SEBS (polystyrene-block-poly(ethylene-co-butylene)-block-polystyrene copolymer). They also integrated a deformable MSC with a standard light-emitting diode to demonstrate the feasibility of MSC as a deformable power source (Fig. 1).

Test Results of the Micro-Supercapacitor

Key to their process was that the underlying stretchable SEBS substrate was not damaged during the laser ablation of EGaIn and graphene layers, thus maintaining the flexibility of the MSC device. The areal capacitance of the resulting MSC retains its original value even after stretching up to 1,000 cycles. The fabricated MSCs operate stably under various mechanical deformations, including stretching, folding, twisting, and wrinkling.

Further, owing to the intrinsic liquid characteristics of EGaIn current collector, the areal capacitance of the fabricated MSC retained 90% of its original value even after repetitive folding and 20% stretching up to 1,000 cycles (Fig. 2).

Their work is detailed in a 10-page paper “Deformable micro-supercapacitor fabricated via laser ablation patterning of Graphene/liquid metal” published in npj Flexible Electronics, along with a 13-page Supplementary Information posting.

About the Author

Bill Schweber

Contributing Editor

Bill Schweber is an electronics engineer who has written three textbooks on electronic communications systems, as well as hundreds of technical articles, opinion columns, and product features. In past roles, he worked as a technical website manager for multiple topic-specific sites for EE Times, as well as both the Executive Editor and Analog Editor at EDN.

At Analog Devices Inc., Bill was in marketing communications (public relations). As a result, he has been on both sides of the technical PR function, presenting company products, stories, and messages to the media and also as the recipient of these.

Prior to the MarCom role at Analog, Bill was associate editor of their respected technical journal and worked in their product marketing and applications engineering groups. Before those roles, he was at Instron Corp., doing hands-on analog- and power-circuit design and systems integration for materials-testing machine controls.

Bill has an MSEE (Univ. of Mass) and BSEE (Columbia Univ.), is a Registered Professional Engineer, and holds an Advanced Class amateur radio license. He has also planned, written, and presented online courses on a variety of engineering topics, including MOSFET basics, ADC selection, and driving LEDs.