Magnetic Packaging Helps Slash DC-DC Module Size Even Further

Just when you think that the size of lower-power DC-DC modules simply can’t shrink any further, innovative developments in materials and design both challenge and contradict that otherwise sensible assumption. Consider the latest series of power modules introduced by Texas Instruments. Based on a new magnetic-packaging technology, these units have dramatically smaller size without performance compromise, addressing our apparently insatiable need for DC-DC modules and localized power regulation (Fig. 1).

The six new power modules are designed to improve power density, enhance efficiency, and reduce EMI—hitting a power-module wish-list “trifecta.” They leverage TI's proprietary MagPack integrated magnetic packaging technology, shrinking their size by up to 23% versus competing modules (Fig. 2).

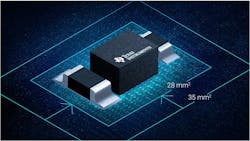

Smallest 6-A Power Modules to Date

Three of the six new devices—the TPSM82866A, TPSM82866C, and TPSM82816—are said to be the industry's smallest 6-A power modules, supplying an industry-leading power density of nearly 1 A per square millimeter (see table). They offer a variety of basic voltage/current pairings as well as additional functions and features, such as an I2C interface, integrated inductor and noise-filtering capacitors, and more. Also important, they reduce electromagnetic interference (EMI) radiation by 8 dB and simultaneously improve efficiency by up to 2% compared to predecessors.

This innovation is based largely, but not entirely, on advances in magnetic materials, and it didn’t come quickly. Noted Jeff Morroni, director of power management research and development at TI's Kilby Labs, "After nearly a decade in the making, TI's integrated magnetic packaging technology enables power designers to meet the defining power trend that has shaped our industry—pushing more power in smaller spaces efficiently and cost-effectively."

Magnetic Packaging Translates into More Power in Less Space

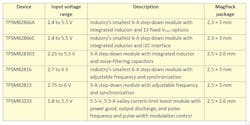

By leveraging TI's exclusive 3D package-molding process, MagPack packaging technology maximizes the height, width, and depth of the power modules to push more power in a smaller space. The magnetic packaging technology includes an integrated power inductor with proprietary, newly engineered material.

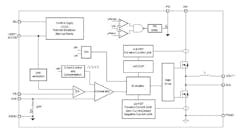

The tiny modules embed a significant amount of complexity, as seen in the example of the basic TPSM82866A, a 2.4- to 5.5-V input, 6-A output step-down power module with integrated inductor (Fig. 3).

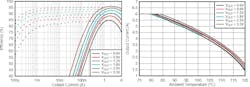

Their diminutive size doesn’t lead to a compromise in efficiency and thermal performance (Fig. 4), nor EMI considerations (Fig. 5).

Preproduction quantities of these new power modules with MagPack packaging technology are available now. Each module is supported by its own evaluation board ($49).

References

Texas Instruments, “MagPack technology: Four benefits of new power modules that can help you pack more power in less space.”

Texas Instruments, SSZTD45, “Power module package types and their benefits.”

About the Author

Bill Schweber

Contributing Editor

Bill Schweber is an electronics engineer who has written three textbooks on electronic communications systems, as well as hundreds of technical articles, opinion columns, and product features. In past roles, he worked as a technical website manager for multiple topic-specific sites for EE Times, as well as both the Executive Editor and Analog Editor at EDN.

At Analog Devices Inc., Bill was in marketing communications (public relations). As a result, he has been on both sides of the technical PR function, presenting company products, stories, and messages to the media and also as the recipient of these.

Prior to the MarCom role at Analog, Bill was associate editor of their respected technical journal and worked in their product marketing and applications engineering groups. Before those roles, he was at Instron Corp., doing hands-on analog- and power-circuit design and systems integration for materials-testing machine controls.

Bill has an MSEE (Univ. of Mass) and BSEE (Columbia Univ.), is a Registered Professional Engineer, and holds an Advanced Class amateur radio license. He has also planned, written, and presented online courses on a variety of engineering topics, including MOSFET basics, ADC selection, and driving LEDs.