OV/UV Window Supervisor Interfaces with 400/800-V Auto Power Packs

What you’ll learn:

- The need for additional monitoring of high-voltage EV battery packs.

- Where and how this monitoring is inserted in the high-voltage path.

- How an evaluation eases design in, with cautions.

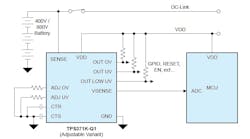

When it comes to the high-voltage DC power packs in electric vehicles and battery energy storage systems (BESS), significant supervision is required to monitor conditions and ensure safety. That’s where the TPS371K-Q1 from Texas Instruments can assist. This device is a supervisor for automotive voltage monitoring for high-voltage DC-link measurements (Fig. 1).

The device's SENSE pin can be directly connected to 400- or 800-V automotive-battery systems and the DC link for continuous monitoring of overvoltage (OV), undervoltage (UV), and low-undervoltage (LUV) conditions. In addition, the TPS371K-Q1 has an integrated VSENSE high-speed buffer for supply-voltage measurements; this buffer has a low output impedance that can directly drive ADC inputs. (VSENSE is a scaled-down voltage of the SENSE pin input.)

The combination of voltage supervisor and integrated buffer allows for the smallest signal-chain size for direct monitoring of 400- and 800-V systems. This combination enables redundant digital and analog always-on voltage-fault monitoring.

Supervisor for Automotive Safety

The device is not only auto-centric, it’s AEC-Q100 qualified for automotive applications (temperature grade 1: –40 to +125°C). It features 1% overvoltage and undervoltage outputs, fast detection time (<5 µs) to help minimize system fault-tolerant time intervals, and −30- to −60-V low undervoltage output.

>>Check out this TechXchange for similar articles and videos

The TPS371K-Q1 is designed for safety applications. An output latching feature helps bring the system to safe state, and a built-In self-test (BIST) monitors device functionality and enhances system protection. It’s offered in fixed-voltage as well as adjustable-voltage versions.

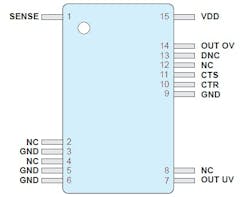

The supervisor comes in a 12.8- × 7.4-mm SOIC 15-pin package. As the device directly handles high voltages, the unusual pin arrangement is dictated by best practices and regulatory mandates (Fig. 2). Among these pins are user-programmable Release Time Delay, Sense Time Delay, and Undervoltage Threshold; BIST enable; and BIST Status Output.

Evaluation Module and User Guide

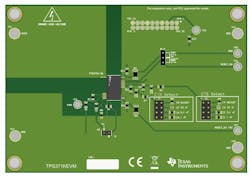

An IC such as this one benefits from an evaluation module, which in this case is the TPS371KEVM—it supports an input-voltage range of 0 to 1,500 V (Fig. 3). The module provides a sample design along with test points for all input and output pins of the TPS371K-Q1 so that designers can capture measurements and gain familiarity with the device. The associated User Guide has operating instructions, schematic diagram, PCB layout, component placement, and bill of materials.

The User Guide also wants you not to get too casual with the module: one full page of the 13-page guide is devoted to high-voltage warnings of various sorts. After all, you’re dealing with lethal voltage here—if you don’t know how to do that, just don’t. The module is designed for “qualified professional users having training, expertise, and knowledge of electrical safety risks in development and application of high-voltage electrical circuits.”

There’s one other caveat to keep in mind. TI notes, “This product is not in production, although prototype or experimental parts are available for purchase. This product may be subject to changes during engineering validation until it is released to production.”

So, you’ll have to decide if this part is worth taking a chance on. Although I sense TI is just being very cautious here—in my experience, that’s an inherent trait of most “analog-centric” vendors—and they will deliver it, as the market it serves needs parts with these functions.

>>Check out this TechXchange for similar articles and videos

About the Author

Bill Schweber

Contributing Editor

Bill Schweber is an electronics engineer who has written three textbooks on electronic communications systems, as well as hundreds of technical articles, opinion columns, and product features. In past roles, he worked as a technical website manager for multiple topic-specific sites for EE Times, as well as both the Executive Editor and Analog Editor at EDN.

At Analog Devices Inc., Bill was in marketing communications (public relations). As a result, he has been on both sides of the technical PR function, presenting company products, stories, and messages to the media and also as the recipient of these.

Prior to the MarCom role at Analog, Bill was associate editor of their respected technical journal and worked in their product marketing and applications engineering groups. Before those roles, he was at Instron Corp., doing hands-on analog- and power-circuit design and systems integration for materials-testing machine controls.

Bill has an MSEE (Univ. of Mass) and BSEE (Columbia Univ.), is a Registered Professional Engineer, and holds an Advanced Class amateur radio license. He has also planned, written, and presented online courses on a variety of engineering topics, including MOSFET basics, ADC selection, and driving LEDs.