Power Supply Controls AC-DC and DC-DC Conversion with Single MCU

A new reference design developed by ROHM Semiconductor uses a single microcontroller (MCU) to control both sides of the AC-DC power supply — the power-factor-correction (PFC) AC-DC converter stage and a flyback DC-DC converter stage — at the same time. By using a single controller to support both sides, ROHM said it can reduce costs and save power at the system level.

The REF67004 is the latest to leverage the company’s LogiCoA architecture, which brings together the advantages of both analog and digital control. The reference design integrates a digitally managed power-supply circuit based on its LogiCoA MCU with an analog-controlled power stage circuit featuring silicon MOSFETs and gate-driver ICs. The power supply uses the critical-conduction-mode (CCM) PFC to convert the AC input to DC and a flyback converter to translate the DC bus voltage to a regulated 24-V DC output.

The reference design comes around a year after ROHM released its DC-DC buck-converter reference design, the REF66009, giving engineers the ability to evaluate the new LogiCoA power-supply architecture.

What’s the Difference Between Digital and Analog Power Control?

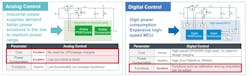

In a fully digital power supply, the digital controller must be able to accurately measure current, voltage, and other output characteristics and then compare them to reference values. The CPU or DSP uses the feedback to determine the optimal pulse-width-modulation (PWM) waveform to control the switching of the power FETs and deliver the desired output. The controller must carry out these computations fast so that the power-control algorithms can react to changing loads as well as thermal or other external conditions.

Digital control is all about flexibility and precise control. High-speed CPUs and DSPs can precisely monitor and control parameters such as voltage and current, improving power efficiency and system reliability.

Digital control can also enable more advanced features, such as custom parameter settings and diagnostics, which can be challenging to implement with analog control. However, digital controllers tend to be costly and consume a comparatively large amount of power, posing challenges for power designers (Fig. 1).

The digital control of switching power supplies is firmly established in everything from electric-vehicle (EV) onboard chargers (OBCs) to power-supply units (PSUs) in data centers that output many thousands of watts. But beyond high-end power-supply circuits and DC-DC converters requiring very fast response times and fine-grained control over the power supply’s operation, digital controllers are relatively rare in designs that output tens to hundreds of watts.

In these cases, it’s preferable to use analog controllers to output the PWM signals, analog compensators to smooth out any undesirable fluctuations in the control loop, and other non-digital building blocks, said ROHM.

In the case of a DC-DC converter, the control loop can be characterized by the frequency response. The frequency response impacts the switching regulator’s precision, stability, and reaction time to transients and, in turn, how closely it keeps to a set output voltage under variations in input voltage, load, and duty cycle.

>>Check out this TechXchange for similar articles and videos

Whether assembled out of analog devices or running in a digital controller, the compensator adjusts control-loop bandwidth and tailors the frequency response. It also determines how well the power supply works.

Though it lacks the same level of flexibility and reliability, analog control stands out for its simplicity. The technology can deliver fast response times and high stability due to its continuous analog feedback, said ROHM. But while they can also avoid the cost, power, and complexities involved with digital control, analog-only configurations tend to have trouble operating efficiently across different load conditions and input voltages.

The LogiCoA MCU: The Power Supply’s Digital Control Center

The LogiCoA solution bridges the gap between analog and digital control, which ROHM claims can deliver the same functionality as a fully digital power supply for approximately the same power and cost as analog designs. The company said the new REF67004 is ideal for integration into both consumer- and industrial-grade power supplies with outputs ranging from 50 W to 1 kW, which is analog control’s domain.

The LogiCoA MCU serves as the digital control center of the power supply. It’s paired with a separate analog compensator comprised of silicon MOSFETs and other analog and power devices, including op amps and current sensors. The feedback control, which tends to require intense computations in digital-control systems, is facilitated by the analog comparator in the MCU and analog compensator on the PCB (Fig. 2).

Innovations in power devices such as GaN and SiC are crucial for improving power density. But it's equally important to have drivers and controllers that can fully tap into the capabilities of those devices. Additionally, safety and diagnostics features are essential for digital power control. LogiCoA stands out because it can flexibly adapt to these innovations through software, eliminating the need for constant development of new MCUs.

- Kenichi Morioka, Product Marketing Manager, ROHM

The MCU is based on a 16-bit RISC CPU core with a maximum clock frequency of 16 MHz. The LogiCoA also leverages a 12-bit analog-to-digital converter (ADC) to convert output voltage into a digital value so that the control loop can adjust it accordingly, and an 8-bit digital-to-analog converter (DAC) to translate the desired output voltage from the digital control system into an analog signal to set the power supply’s output.

One of the core building blocks is the high-resolution 16-bit PWM controller. The timer delivers tighter control of the PWM signals that determine output power by varying the power MOSFET’s on and off times.

As Kenichi Morioka, Product Marketing Manager at ROHM, explained to Electronic Design, “The PWM controller can dramatically and dynamically adjust the power switch based on signals from the comparator in the MCU. As a result, switching operations can be performed independently of the CPU, making it possible to use a less powerful CPU while reducing costs. This also makes it adaptable to a wide range of power-supply topologies.”

LogiCoA also features a calibration function that compensates for variations in the external component characteristics, allowing it to handle high-precision voltage configuration and overcurrent protection (Fig. 3). In turn, it reduces design margins, making it possible to select more compact power devices and passive components like capacitors and inductors, thus saving space and cutting down on costs at the system level.

>>Check out this TechXchange for similar articles and videos

About the Author

James Morra

Senior Editor

James Morra is the senior editor for Electronic Design, covering the semiconductor industry and new technology trends, with a focus on power electronics and power management. He also reports on the business behind electrical engineering, including the electronics supply chain. He joined Electronic Design in 2015 and is based in Chicago, Illinois.