Advanced TIMs Help Overcome Power-Density Thermal Challenges

Power density plays a critical role in making power electronic systems smaller, more efficient, and more cost-effective. As power density increases, so does the heat generated inside a device. Managing this heat efficiently is essential to maintaining high performance and preventing damage.

Smaller devices concentrate more heat in less space, making cooling a challenge. The goal is to keep temperatures low while maintaining or even increasing power output. If heat isn’t properly removed, internal temperatures rise, leading to energy losses, reduced efficiency, and potential damage. To address this, advanced thermal-management techniques are employed, such as:

- Thermal vias and direct-bond-copper (DBC) substrates

- Liquid-cooling systems

- Compact packaging like small-outline transistors (SOTs)

- High-performance thermal interface materials

Thermal interface materials (TIMs) have seen some important new developments in recent years. In particular, graphene-related technology and carbon nanotubes can help electronic engineers achieve their design goals.

What are the Key Developments in Graphene-Enhanced TIMs?

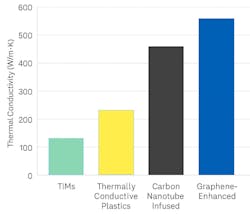

Graphene has exceptionally high thermal conductivity of up to 5,000 W per meter kelvin (W/m·K), so it has potential value in TIM pastes, pads, films, and foils to improve heat spread from high-power semiconductors. This is emerging in premium applications like high-performance computing and electric-vehicle (EV) inverters (see figure).

There are many types of graphene-enhanced TIMs:

- Vertically oriented graphene structures: These structures, often prepared through methods like filtration or chemical vapor deposition (CVD), aim to align graphene flakes vertically within the polymer matrix. This vertical alignment creates direct heat transfer paths, leading to higher through-plane thermal conductivity.

- Graphene/alumina/epoxy composites: Pod-like structures with vertically aligned graphene, leading to a potential through-plane thermal conductivity of 13.3 W/(m·K).

- Graphene/polyurethane films: Prepared by gap-coating and hot-pressing, they demonstrate a thermal conductivity of 26.3 W/(m·K).

- Graphene-fiber-based TIMs: These utilize the high thermal conductivity (~1200 W m–1 K–1) and flexibility of graphene fibers (GFs). These materials can achieve high through-plane thermal conductivity and low thermal contact resistance.

- Pre-constructed 3D graphene networks: This method involves creating a three-dimensional network of graphene flakes before backfilling it with a polymer matrix. It aims to improve efficiency and reduce thermal resistance. Examples include:

- Layered graphene aerogels: Prepared by directional freeze-drying and graphitization, these aerogels with densely stacked graphene layers can achieve through-plane thermal conductivity of 20.0 W/(m·K). Researchers have also produced graphene-infused foams, which have shown value in thermal management.

- Graphene/epoxy composites: Synthesized using dual assembly with a polyurethane template, these composites can exhibit thermal conductivity between 56.8-62.4 W/(m·K).

- Graphene-enhanced thermal greases: Graphene is added as a filler to thermal grease to enhance its thermal conductivity. This type is widely used to cool electronic components like CPUs, GPUs, and LEDs.

- Hybrid fillers: Using a combination of materials, such as graphene and boron nitride, can potentially provide independent control over electrical and thermal conduction, while also increasing thermal conductivity.

What are the Key Developments in Carbon-Nanotube Arrays?

Carbon nanotubes (CNTs) have a wide range of potential roles in electronics, including thermal mitigation. Vertically aligned arrays can be used like micro "thermal brushes,” with high anisotropic conductivity (e.g., conductivity primarily in one axis) — excellent in the vertical direction with minimal lateral spreading. This makes them useful in microprocessors, power amplifiers, and RF devices.

>>Download the PDF of this article, and check out the Series Library for similar articles

Some types of CNT arrays and related structures that are being explored for potential power-electronics applications fall into four main categories:

1. Vertically aligned carbon-nanotube (VACNT) arrays

- Thermal interface materials (TIMs): VACNT arrays are considered promising candidates for TIMs due to their high thermal conductivity, good stability, and desirable mechanical properties. They can help efficiently dissipate heat from high-power electronic devices, which is essential for performance and reliability.

- Thermal management: VACNT arrays can be used for thermal management of electronic circuits. They have been used to fabricate coolers that are significantly lighter than copper structures with similar cooling properties.

- Reinforcing composites: VACNT arrays have also been demonstrated as reinforcing components in laminated composites.

- Electrochemical sensors: VACNT arrays have found use in electrochemical immunosensors.

2. Horizontally aligned carbon-nanotube (HACNT) arrays

- Integrated circuits (ICs): HACNT arrays are considered promising for high-performance, low-power integrated circuits in the post-Moore era. Aligned arrays with high purity and suitable density can provide enhanced current-driving ability and smaller intrinsic capacitance, leading to improved circuit performance.

- Field-effect transistors (FETs): HACNT arrays are used to construct high-performance FETs. Researchers developed methods to create wafer-scale, aligned, high-density, and purified semiconducting CNT arrays suitable for FETs and integrated circuits.

3. CNT films and composites

- Conductive films: Carbon-nanotube films are being developed as replacements for indium tin oxide (ITO) in applications like touchscreens and flexible displays. They offer advantages like mechanical robustness and the potential for low-cost, printable deposition methods.

- CNT-metal composite films: Combining CNTs with metals like copper (Cu) and palladium (Pd) can enhance electrical conductivity and mechanical properties. CNT-Cu composites have shown significantly higher current-carrying capacity than pure Cu or Au, with similar electrical conductivity to pure Cu.

- Conductive adhesives and connectors: CNTs can be used as conductive fillers in adhesives and connectors for electronics packaging and interconnection.

- Thermal conductivity enhancement: CNT networks and composites can demonstrate enhanced thermal conductivity, particularly in the axial direction. High-quality VACNT arrays, after thermal annealing, can reach thermal conductivities of up to 80 W/mK.

4. Hybrid structures

- 3D graphene/CNT aerogels: Entangled CNTs can bond graphene sheets in aerogels, improving elasticity and increasing thermal conductivity under compression.

- Vanadium oxide-CNT hybrid: Vertically arranged vanadium oxide-coated CNTs can serve as active materials in supercapacitors, significantly boosting areal and volumetric capacitance.

- Layered structures: Multi-layer systems of MWCNT sheets can be created, with stacking influencing thermal conductivity and anisotropy.

Pushing Adoption of CNT-based Electronics

While CNT arrays and related structures show great potential for power electronics, challenges remain in areas such as scalability, manufacturing cost, defect control, and achieving optimal interfacial interactions between CNTs and other materials. Despite these challenges, ongoing research and advances in synthesis and processing methods are pushing the boundaries for widespread adoption of CNT-based electronics

As they mature, all of these technologies potentially merit considerations for power electronics. Actual product selection depends on their characteristics, which need to include high thermal conductivity, particularly in the through-plane direction (z-axis) — crucial for efficient heat dissipation in power electronics.

For many power electronics applications, it's also important that the TIMs provide electrical insulation, reliability, and lifespan performance, especially under high-temperature conditions. Finally, TIMs need to be mechanically compliant to ensure good contact between the heat-generating component and the heatsink, reducing contact thermal resistance.

Other TIMs with advancing technology may also bear exploration and consideration, including phase-change materials (PCMs) with enhanced fillers, silicone-free TIMs, thermally conductive gap fillers with structural compliance, metal-based TIMs (sintered silver, liquid-metal alloys), and 3D-printed TIMs.

These modern, advanced power-density TIMs have the potential to enable smaller heatsinks and enclosures by improving heat dissipation per unit volume while supporting higher switching frequencies and tighter component placement (thanks to reduced thermal resistance). They also help ensure reliable operation at higher power loads, which can be especially important in GaN/SiC power electronics, where thermal margins are tight.

References

High-performance Graphene-enhanced Thermal Interface Technology for Electronic Cooling Applications.

>>Download the PDF of this article, and check out the Series Library for similar articles

About the Author