Density Meets the Deep: Engineering EV Systems for Maritime Environments

What you'll learn:

- Thermal runaway containment issues involving batteries.

- Dealing with salt fog and creepance/clearance issues.

- How can electric motors and drives resist saltwater and mechanical wear?

- How can auxiliary electronics meet both density and ruggedness requirements?

- How marine density can lead to a unified design philosophy.

There’s probably no exact total number for electric boats and ships now afloat and in operation, but the market includes over 100 manufacturers and thousands of individual vessels.

Driven by national and international regulations and a desire to reduce the direct use of fossil fuels, the number of electric vessels is growing rapidly, with estimates suggesting the market value will exceed $20 billion by 2027. Most of today's electric boats are smaller recreational craft, though larger electric or hybrid tugs, ferries, and ships are becoming increasingly common.

As electric propulsion gains global momentum, maritime platforms — from autonomous surface vessels to hybrid ferries and electric harbor craft — are pushing rapidly toward higher power density and tighter packaging where possible. But unlike land-based electric vehicles (EVs), which already grapple with vibration, thermal stress, and electromagnetic complexity, marine EV systems face a harsher and more unpredictable environment: salt-rich air, conductive spray, persistent humidity, and regulatory regimes that span multiple international jurisdictions.

Making EV circuits denser is now both an engineering necessity and a compliance challenge. Operators want longer range, more payload, quieter operations, and reduced emissions. Shipyards want systems that are easy to install and service. Designers want to minimize footprint while improving reliability.

Moreover, regulatory bodies — from the American Bureau of Shipping (ABS) and Det Norske Veritas (DNV) both leading classification societies that set technical standards for the safety, quality, and environmental performance of vessels to Lloyd’s Register, IEC, and ISO — are tightening requirements around safety, galvanic isolation, thermal performance, and environmental robustness.

What are the Thermal-Runaway Containment Issues Involving Batteries?

Maritime EVs can’t afford bulky thermal-runaway barriers. Compact battery racks may only have millimeters of spacing between modules, raising propagation risk — a runaway event can spread faster in tight arrays. It also presents ventilation design challenges since exhaust paths must be short, controlled, and safe where crew or passengers are present.

>>Download the PDF of this article

In addition, there are cooling-loop constraints because marine systems must accommodate both cold seawater and warm engine-room spaces. As a result, heat exchangers need corrosion-resistant plates and pumps.

Maritime battery installations must comply with:

- IEC 62619: safety requirements for industrial lithium batteries

- IEC 60092-301/502: electrical installations on ships, including flammability and insulation requirements

- DNV and ABS rules that cover fire suppression, enclosure design, gas detection, and zoning.

Meeting these standards while increasing module density requires precise control of clearances, robust potting/coating, and the elimination of galvanically incompatible metals.

Dealing with Salt Fog and Creepage/Clearance Compression

High-density power electronics — DC-DC converters, traction inverters, onboard chargers — are usually the first casualties of salt-air exposure. As designers push for smaller gate drivers, closer-spaced MOSFETs/IGBTs/SiC modules, and compact laminated bus structures, creepage and clearance distances shrink to the margins allowed by land-based EV standards.

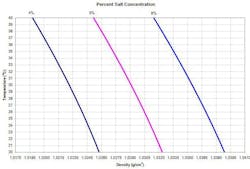

But salt changes the math. Salt fog creates conductive film on surfaces, reducing effective creepage (see figure). Moisture ingress increases dielectric constant and accelerates partial discharge. In particular, fine-pitch connectors can become failure points when salt crystallizes.

Thermal Management in Confined, Wet Compartments

Cooling systems must now integrate corrosion-proof cold plates, dielectric liquids, or seawater heat exchangers while at the same time, high-density power stages produce steep thermal gradients, and in a marine installation.

For example, heat rejection to ambient air is poor due to humid, enclosed compartments. And condensation can form on cold plates or housings, requiring insulation or active dehumidification. Furthermore, EMC filters become larger when additional shielding is needed, counteracting efforts to minimize size.

Switching Devices and Packaging Challenges

Silicon-carbide (SiC) and gallium-nitride (GaN) devices enable compact, high-frequency designs. However, their packaging must withstand continuous vibration and hull flexure, aggressive corrosion of leadframes and bond wires, transients from long cable runs typical in ships, and galvanic interaction with surrounding metallic structures.

In short, the maritime environment often forces designers to adopt ruggedized, molded modules with reinforced housings. This reduces the theoretical density gains from next-generation semiconductors.

Regulatory Framework

In addition to pure engineering considerations, power-conversion systems must align with:

- IEC 60092-201/501: power distribution and electrical equipment in ships

- ISO 16315: environmental requirements for marine equipment

- EMC standards (IEC 60533): stricter due to large metal hulls acting as resonant cavities

The path to dense maritime power electronics is therefore tied tightly to insulation robustness, conformal coatings, and graded sealing strategies (IP67/IP69K with salt-spray certification).

How Can Electric Motors and Drives Resist Saltwater and Mechanical Wear?

Electric propulsion motors used in marine EVs, whether permanent-magnet synchronous machines or high-density induction units, operate near the waterline or below deck where moisture and salt concentration are highest.

Key concerns include galvanic attack on aluminum housings, rotor sleeves, and stainless fasteners, ingress of salt mist into end bells or stator windings, accelerating insulation aging, and shaft-seal degradation due to continuous splash exposure.

Attempts to implement compact design leave less room for labyrinth seals, desiccant paths, and pressure-equalization systems typically used to manage moist air ingress.

Thermal Density vs. Cooling Options

Motor designers want high slot fill, high flux density, and minimal frame volume. But with limited ventilation options and a regulated acoustic environment (especially in passenger vessels), forced cooling is difficult.

As a result, maritime motors often require liquid-cooling jackets with corrosion-resistant channels, encapsulated windings to block moisture, and embedded temperature sensors with hermetic connectors.

However, these protective measures consume space, complicating efforts to make systems more compact.

Regulatory Landscape

Motors and drives must satisfy ABS or DNV rules for rotating electrical machinery. They often require enhanced intrusion-protection (IP) ratings (IP56–IP68), certification of insulation systems for humid/saline atmospheres, and vibration testing per IEC 60092-504 and ISO 20311.

Naturally, dense motor designs must be accompanied by equally robust sealing and monitoring strategies. Effective sealing and protection for electric motors and drives in marine environments center on robust enclosures, corrosion-resistant materials, and high-performance seals that keep out saltwater and contaminants.

In addition to IP, consider NEMA 4X enclosures to withstand high-pressure spray, submersion, and corrosive conditions. For rotating shafts, use labyrinth or magnetic-fluid seals or PTFE rotary seals for low friction and high-speed durability. Seal housings, lids, and flanges with high-quality O-rings and gaskets made from silicone or fluoropolymer elastomers. In the case of critical penetrations, such as propeller shaft assemblies, it may be necessary to use multiple lip seals with oil-filled header tanks for lubrication and extra protection.

In severe environments, fully hermetically sealed motors prevent all moisture and contaminant ingress, and resin-impregnated (“ultra-sealed”) windings can provide moisture immunity and improved heat transfer.

How Can Auxiliary Electronics Meet Both Density and Ruggedness Requirements?

While batteries, power electronics, and motors handle the propulsion workload, modern maritime EVs rely on dense networks of sensors, controllers, and communications devices that must remain functional in a corrosive environment.

Sensor Integration and Redundancy

Compact sensor arrays — IMUs, GNSS units, radar processors, pressure sensors, thermal cameras — face corrosion of connectors and housings, condensation on optical elements, and even possible salt bridging on fine-pitch boards.

Increasing density means more components sharing enclosures, raising thermal load, and the risk of cross-contamination from salt or moisture.

Navigation, Safety, and Communication Electronics

Autonomy and electrification are converging, making navigation systems more computationally demanding and thermally intensive. Dense boards with multicore processors and RF modules must be shielded from both salt and the strong magnetic fields of propulsion motors.

Marine EVs rely on redundant communication networks, such as CAN, Ethernet, fiber, NMEA 2000, and wireless links. Higher density means closer routing of power and data cables, increasing susceptibility to galvanic interference, salt-induced leakage and false signaling, and potential EMC coupling within metal compartments.

Regulatory Requirements

Control and navigation electronics fall under:

- IEC 60945: maritime navigation and radio communication equipment

- IEC 60092-504: control engineering for shipboard applications

- Military-grade options (if applicable): MIL-STD-810 for vibration, moisture, and salt fog

Meeting these standards while miniaturizing systems requires hybrid environmental barriers: conformal coatings, potting compounds, sealed cable glands, humidity-controlled housings, and likely even fault-tolerant network architectures.

How Marine Density Can Lead to a Unified Design Philosophy

The central challenge to dense maritime EV circuitry is dual: increase energy and functional density while increasing environmental robustness. Achieving both requires a layered approach:

- Material engineering: galvanically compatible metals, ceramic-filled potting, and multi-stage conformal coatings.

- Mechanical barriers: double-sealed housings, sacrificial anodes, pressure-equalization valves, IP67/68 enclosures.

- Electrical design: larger creepage margins than land EVs, redundant isolation, and carefully managed ground planes.

- Thermal management: liquid-cooling loops, salt-resistant heat exchangers, and humidity-controlled modules.

- Regulatory alignment: early collaboration with classification societies to avoid redesign cycles.

In the maritime world, density can’t come at the cost of longevity. Electric vessels must survive decades of exposure, something land EVs aren’t as likely to need to do.

References

Interaction of advanced micro/nano electronics and materials with marine environment

Internet of Things in Marine Environment Monitoring: A Review

>>Download the PDF of this article

About the Author