Innovative Design Flattens and Shrinks Gas Discharge Tubes

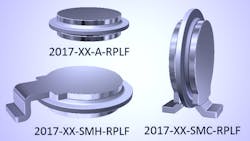

A new Gas Discharge Tube (GDT) from Bourns provides a breakthrough flat package for a volume and space-saving circuit protection design. The two-electrode Model 2017 Series FLAT® GDT meets the need for more sensitive overvoltage protection requirements in high density and space-restricted applications (Fig. 1). This new series delivers a 75% savings in volume compared to a standard 8 mm Bourns GDT. Typical applications for the new GDT include Telecom CPE, industrial communications, surge protection devices, and high-density PCB assemblies.â

The FLAT® GDT is consistent with electronic designs that continue to require higher density and performance in smaller packages. However, as designs become increasing smaller, they are more susceptible to damage from transients such as lightning and high voltage surges. Therefore, circuit protection technology must follow with smaller, more robust devices. GDTs are a popular circuit protection solution because of their low capacitance, low leakage characteristics and high surge current handling capability.

Traditional high current GDTs are cylindrically shaped devices typically measuring 8 x 6 mm in size. These dimensions are critical to effectively handling surge energy and maintain electrical isolation. Their diameter and thermal mass provide much of the current handling capabilities for the GDT. Unfortunately, the larger conventional GDTs offer reliable overvoltage protection, at the cost of valuable PCB space.

While reducing height and overall volume, Bourns’ new FLAT® GDT technology is able to maintain the device’s robust isolation, current-handling and overvoltage protection capabilities. This new compact GDT maintains surge current ratings, low leakage, low capacitance and insertion loss as current standard 8x6mm GDTs.

The FLAT® GDT design is patterned after a high voltage insulator, as shown in Figure 2. Similarly, the new GDT design employs “wrinkled” insulating pathways while maintaining the internal gap of the GDT. This allows the GDT to be compressed in the axial direction, reducing its overall volume/size.

The Model 2017 Series is an ITU K.12 Class III GDT device rated at 10 kA on an 8/20 μs waveform. The series features DC breakdown voltages ranging from 90 to 500 V. Maximizing its design flexibility, the FLAT® GDT offers multiple mounting options including horizontal for bottom-side PCB, as well as vertical surface mount versions and a leadless design for cartridge or clamp fit applications. The Model 2017 FLAT® GDT is RoHS compliant.

Gas Discharge Tube Basics

A gas discharge tube consists of an arrangement of electrodes in a gas within an insulating, temperature-resistant envelope. Gas-filled tubes exploit phenomena related to electric discharge in gases, and operate by ionizing the gas with an applied voltage sufficient to cause electrical conduction. The voltage required to initiate and sustain discharge depends on the pressure and composition of the fill gas and geometry of the tube.

The fundamental gas ionization mechanism is the Townsend discharge, which is the sustained multiplication of electron flow by ion impact when it reaches a critical value of electric field strength for the density of the gas. Increasing the electric field causes various phases of discharge. The gas used dramatically influences the parameters of the tube. The breakdown voltage depends on the gas composition and electrode distance, as described by Paschen's law.

GDT Operation

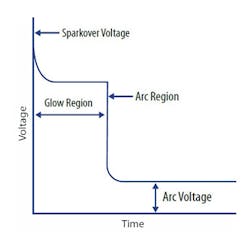

Figure 3 shows the basic switching characteristic of a GDT. When a voltage disturbance reaches the GDT’s sparkover value, the GDT will switch into a virtual short, known as the arc mode. In the arc mode, the GDT practically shorts the line, diverting the surge current through the GDT to ground and removes the voltage surge from the plant and equipment. At normal operating voltages below the GDT rated DC sparkover voltage (measured at a rate of rise between 100 to 2000 V/s), the GDT remains in a high impedance off-state condition. With an increase in voltage across its conductors, the GDT will enter into its glow voltage region.

The glow region is where the gas in the tube starts to ionize due to the charge developed across it. During the glow region the increase of current flow will create an avalanche effect in gas ionization that will transition the GDT into a virtually short circuit mode and current (dependent on the impedance of the voltage source) will pass between the two conductors.

The voltage developed across the GDT with a short circuit condition is called the “Arc Voltage” VARC. The transition time between the glow and arc region is dependent on the available current of the impulse, the distance and shape of the electrodes, the gas composition, gas pressure and emission coatings.

The GDT will switch back or reset into a high impedance state once there is not enough energy to keep the device in the arc condition. This is sometimes also called the “Extinguishing Voltage, Holdover Voltage or Impulse Reset Voltage”. Due to the typical arc voltage of less than 10 V, a GDT is ideal for protecting against high-energy impulses and AC power cross conditions. Under AC, the power dissipated (VARC x IGEN) in the device needs to be carefully monitored. GDT are typically not recommended for use in AC power circuits unless used with another protection technology such as an MOV that will limit follow-on current through the device allowing it to safely reset. As an alternative, some GDT devices have a switch grade fail-short mechanism that protects against thermal overload under AC conditions.

It is not a good practice to hold a GDT in its glow region as this significantly reduces its life expectancy. In this condition, significant heat can be developed on the electrodes that can damage its special emission coatings and cause premature failure of the tube. Using a variable AC source such as a curve tracer or equivalent to vary the voltage and power across at its DCBD voltage (DC Breakdown Voltage) should be avoided. It is highly unlikely that a condition could exist in the field that would maintain a GDT in the glow mode. Use of an active proprietary coating on the GDT provides a very low glow-to-arc transition current, which helps reduce or eliminate these issues.

About the Author

Sam Davis

Sam Davis was the editor-in-chief of Power Electronics Technology magazine and website that is now part of Electronic Design. He has 18 years experience in electronic engineering design and management, six years in public relations and 25 years as a trade press editor. He holds a BSEE from Case-Western Reserve University, and did graduate work at the same school and UCLA. Sam was the editor for PCIM, the predecessor to Power Electronics Technology, from 1984 to 2004. His engineering experience includes circuit and system design for Litton Systems, Bunker-Ramo, Rocketdyne, and Clevite Corporation.. Design tasks included analog circuits, display systems, power supplies, underwater ordnance systems, and test systems. He also served as a program manager for a Litton Systems Navy program.

Sam is the author of Computer Data Displays, a book published by Prentice-Hall in the U.S. and Japan in 1969. He is also a recipient of the Jesse Neal Award for trade press editorial excellence, and has one patent for naval ship construction that simplifies electronic system integration.

You can also check out his Power Electronics blog.