Technology Overcomes Efficiency Barrier of Silicon Rectifiers

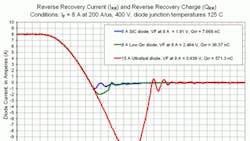

The Q-Series rectifier family from Qspeed Semiconductor has the lowest reverse-recovery-charge (QRR) and the best softness factor of any commercially available high-speed silicon rectifier, according to the copmany (see Figure 1). By virtue of these capabilities, the devices in this series can be substituted for SiC diodes to improve PFC-boost-stage efficiency (see Figure 2), the application for which the series was specifically designed.

“Power supply designers no longer have to work around inferior diodes or use expensive silicon-carbide devices,” said Michael T. Robinson, CEO of Qspeed Semiconductor. “Our Q-Series rectifiers make it easy to improve the efficiency of PFC boost converters and lower MOSFET operating temperatures while minimizing EMI generation, all without the use of snubbers and clamps.”

According to Qspeed, replacing an ultrafast diode with a Q-Series device typically realizes efficiency improvements of 0.5% to 1.5% in the boost-converter stage of 200-W to 1000-W PFC systems. These levels are similar to those obtained when using SiC diodes for the same application.

John Jovalusky, technical marketing manager at Qspeed, states the devices cannot operate at the higher junction temperatures possible with SiC technology. However, the low reverse-recovery currents available in the Q-Series allow these devices to provide the same efficiency of SiC technology at high currents while remaining within the thermal operating limits of conventional silicon technology.

Interestingly, this low-temperature operation is not a direct contributor to the reliability of the series, Jovalusky states. Rather, the use of conventional silicon precludes reliability issues that SiC devices can have due to the latter’s relatively complex manufacturing processes. Furthermore, the Q-Series parts are not Schottky-barrier devices, and do not suffer from surge-current limits or progressive degradation from repeated surges (problems encountered in SiC power-device technology).

Yet, despite the performance of these devices, the technology behind the Q-Series is not suitable for ESD-protection applications in its present state, according to Jovalusky. This is because the technology is optimized for fast-recovering power diodes, with a reverse-breakdown voltage of 600 V; ESD-protection diodes are designed for a maximum breakdown voltage of only 9 V.

The Q-Series presently consists of the LQA03TC600, LQA05TC600 and LQA05TC600, discrete devices that are rated for continuous currents of 3 A, 5 A and 8 A, respectively. These ratings allow the family to cover the respective PFC continuous-power ranges of 200 W to 400 W, 400 W to 700 W, and 700 W to 1000 W.

While the series uses conventional silicon technology, these high-power discrete diodes will probably not be complimented with low-power configurations that can be fully integrated with other devices in applications such as a monolithic PFC stage (an application that would complement monolithic buck converters), according to Jovalusky. This is due to the fact that the electrical properties of the Q-series are enabled partly by unique device fabrication processes.

The fabrication processes for the Q-series are so unique, in fact, that they are not compatible with processes used for Qspeed’s PowerJFETs, devices that share certain geometric structures with the Q-series rectifiers. Therefore, both device types remain discrete, much like the incremental but remarkable advances of silicon-based electronics technology itself.