Acoustic Imaging Of IGBT Modules Through The Heat Sink

IGBT failures are often caused by gap-types defects in or among the materials bonded to create the module. The defects may be voids, delaminations, disbonds, or may involve the tilting of a layer, typically the ceramic rafts that lie between the die at the top side and the heat sink at the bottom. These defects cause failures by blocking the path of heat flow from the die to the heat sink. To find such defects, some form of inspection is needed after assembly.

The ideal detection tool for internal gap-type defects is an acoustic microscope, used after assembly but before encapsulation of the module. The ultrasound pulsed by acoustic microscopes such as Sonoscan’s C-SAM® series is exquisitely sensitive to material interfaces in a sample, both interfaces between solid materials and interfaces between a solid and a gas. The pulsed ultrasound is reflected as a moderate echo signal from well-bonded solid interfaces, but is reflected at >99.99% of the arriving amplitude at solid-to-gas interfaces. This is true even if the gap is as thin as 100Å.

Related Articles

- Inverted Acoustic System Cuts IGBT Failures

- Acoustically Mapping IGBT Module Solder Thickness

- IGBT, Diode Evolution Impacts Design Of High Power Density Inverter Modules

- Test Saturation Voltage to Achieve High Efficiency

The ultrasound-pulsing transducer of the microscope needs to be coupled by water to the surface of the sample being inspected. Although acoustic microscopes are widely used to inspect other components and assemblies, the makers of IGBT modules have generally been reluctant to make use of acoustic microscopes - despite their very high sensitivity to internal gaps - because contaminants in the water may create leakage paths.

To eliminate these risks, Sonoscan has designed a production tool that breaks with convention and places the transducer upside down below the IGBT module, where it can scan the surface of the heat sink and keep the die surface dry. Ultrasound pulsed into the heat sink will reveal gap-type defects and tilt at any depth, from the heat sink to the die attach and the die themselves.

Using the heat sink’s surface to gain acoustic access to the interior of the module lets manufacturers identify and locate defects. The acoustic images also show them precisely what kind of rework is needed to salvage a module. When appropriate, manufacturers can use the acoustic images as a guide to modify production processes to eliminate defects such as voids in the die attach or tilted rafts. Note that acoustic images can also be made through the heat sink surface after encapsulation. Rework is no longer possible, but information about process flaws can be gained.

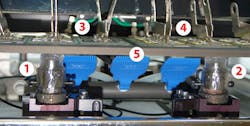

In this new microscope design, the transducer is inverted, and is accompanied by an upward jet of water that maintains ultrasonic coupling with the surface of the heat sink. The microscope can also be equipped with two transducers in order to image two IGBT modules simultaneously for higher throughput.

In Fig. 1, the transducer/water jet assemblies are #1 and #2. Note the water flowing down the exterior of each water jet to a container below, from which it is recirculated. The two IGBT modules are placed in cutouts (#3 and #4) in the stage (#5).

Each transducer raster-scans the bottom surface of the heat sink, pulsing ultrasound into the heat sink and receiving the return echoes from various depths within the module a few microseconds later. Note that the “depths” in this upside-down microscope are located above the transducer. The echoes come only from material interfaces within the module. Interfaces where two solids are well bonded reflect significantly less than 100% of the ultrasound and return a roughly medium-amplitude echo that will be some shade of gray in a monochromatic acoustic image.

But the solid-to-air interface at the top of a gap reflects, as mentioned above, >99.99% of the ultrasound. Voids and other gaps appear bright white in monochromatic acoustic images, and are easily distinguished from other features. At well-bonded interfaces between two solid materials, a portion of the ultrasound crosses the interface and travels deeper, where it may encounter and be reflected by another interface. But ultrasound that encounters a gap travels no deeper because no portion of the pulse crosses the interface.

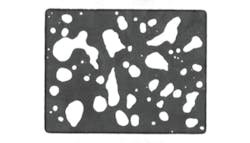

The acoustic image in Fig. 2 was made by pulsing ultrasound upward through the heat sink into the layer of solder that attaches the heat sink to the rafts above. The white areas are voids - air bubbles - in the solder. The voids are both large and numerous, and would block a great deal of the heat that needs to be removed from the IGBT module. They are the kind of defects that a manufacturer would like to find and eliminate via rework before encapsulating the module.

The return echoes to make Fig. 2 were gated on the solder layer and the very first part of the ceramic - that is, the arrival times of thousands or millions of echoes were used only if they indicated that the reflection came from some depth between the top of the solder and the ceramic. The dark gray that fills all of the non-void regions of Fig. 2 represents that relatively low reflection of ultrasound by the solder-ceramic interface.

In Fig. 3, made over the same area, only the echoes from the depth of the die attach material near the top of the module were used for imaging. Two phenomena stand out:

· The die attach material appears everywhere to contain bright white voids (air bubbles) that would block heat from getting any nearer to the heat sink on the bottom of the module.

· In many regions the view of the die is partly blocked by black features that correspond nicely to the voids in Fig. 2. Only the echoes reflected from the die attach depth were used to make Fig. 3, but as these echoes travel toward the transducer they are blocked by the voids in the solder; black here means “no echo received,” and the voids are imaged as black acoustic shadows. Note that the shadows preclude full coverage of the die attach depth, but abundant voids in both the solder and the die attach would destine this module for rework or scrap.

When the acoustic screening of IGBT modules uncovers the need for more thorough diagnosis to illuminate a problem, the inverted system can use several additional modules to provide detailed information.

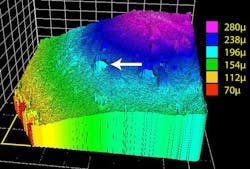

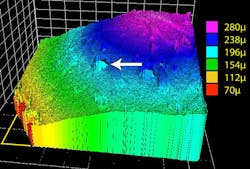

Fig. 4 is the image of the area of the solder layer bonding the heat sink to a raft in an IGBT module. This image was made with a software tool that gives a three-dimensional perspective. The colors in this image indicate not defects but the arrival time of the echoes from an interface. In this case, the colors represent the thickness of the solder. The ceramic raft is apparently tilted, because the solder at the upper right corner (magenta) is about 280 microns thick. Near the lower left corner the solder is only about 70 microns thick. Closer to the lower left corner, in the area outlined in yellow, there appears to be no solder at all. The image suggests that the fluid solder never flowed into this region. The heat sink itself is assumed to be flat; a separate surface flatness software tool can measure the flatness of the heat sink surface. The dark pit-like features are voids in the solder; an arrow marks one.

For makers of IGBT modules, the new inverted system provides three capabilities:

1. The ability to screen unencapsulated IGBT modules for internal flaws without exposing the die to contaminants that may be present in the water.

2. The ability, if needed, to screen larger number of modules by using multiple transducers and multiple stages simultaneously.

3. The ability to use diagnostic software tools to automate accept/reject, to detect process problems, and to feed data back to production.