For an environmentally conscious world, batteries are out, energy harvesting is in. Despite all their benefits, batteries are still potential sources of environmental pollution and eventually wear out. So there has been a concerted effort to harness the energy of natural phenomenon such as vibrations and heat. Notable advances have been made in harvesting such sources over the last few years. Unfortunately, much of this work has been at the micro level and involves microwatts of harvested energy — not nearly enough to handle the power needs of your iPod, let alone more strategic applications.

This has not stopped energy-harvesting visionaries. Engineers have recently been able to squeeze milliwatts of power from relatively small devices. Such advances, coupled with progress in sensing, energy storage, and wireless networking are starting to affect real-world applications. In particular, energy harvesting at the macro level is increasingly viable, thanks to the wider use of wireless-sensor networks. So wireless sensor/energy harvesting combos are starting to show up in infrastructure monitoring, and industrial, commercial, building, and home automation uses, to name a few.

Wireless sensor networks could be the “killer app” that puts energy harvesting into the realm of high volumes and low costs. According to Ian McPherson, president of the Wireless Industrial Networking Alliance, food and beverage, water, gas, and waste water are some of the top industries using wireless communications. They handle applications like tank-level monitoring, overhead crane controls, as well as temperature, flow-meter and conveyor monitoring.

The first such applications likely to go with harvested energy sources are those where worn-out batteries cause major headaches. Mark Buccini, director of worldwide strategic marketing at Texas Instruments, points to underground battery-operated water meters as an application that can benefit from energy harvesting. Such meters have a lifespan of about 20 years. Here, using energy-harvesting sources would eliminate the need for maintenance workers to periodically do some digging for a battery swap.

Indeed, infrastructure monitoring has been one of the sweet spots for energy harvesting technology. The American Society of Civil Engineers says over a quarter of all U.S. bridges (roughly 600,000), are considered deficient or obsolete. The nation's road, sewer, and tunnel infrastructures need major maintenance. Here energy-harvesting could power sensor networks to signal when repairs are in order. The widespread deployment of such devices could not only head off catastrophes but also augment inspections and give advance warnings that let minor fixes head off major expenses.

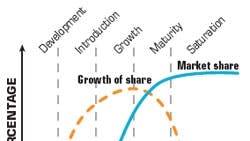

One firm painting a rosy picture for energy harvesting is the market analyst organization The Darnell Group. It concludes that energy harvesting has reached a major inflection point and is moving from an introductory phase into real growth. Senior Darnell analyst Linda Brush points to “the emergence of third-generation products and their significant value proposition and cost savings.”

Many harvesting approaches

Most energy-harvesting approaches scavenge energy from ambient vibrations, wind, heat, or light. Of course, wind and the sun are the two most-scavenged energy sources, but much of the action in milliwatt-scale devices is based on electromagnetic, electrostatic, piezoelectric, and thermoelectric principles.

A piezoelectric crystal converts mechanical strain into electrical current or voltage. The strain can come from sources such as motion, vibration, and acoustic noise to name a few. Save for a few special cases, the piezoelectric effect is only efficient when operating in ac mode. Best results are when time-varying inputs are at the mechanical resonance frequency of the crystal. Most piezoelectric sources generate microwatts to milliwatts of energy.

Commercially available piezoelectric material often takes the form of ceramic fibers and fiber composites. Suppliers include Advanced Ceramics Corp. and Measurement Specialties Inc. which also market piezoelectric film.

Germany's EnOcean Inc. makes a development platform called the Dolphin that has no battery, thanks to these materials. It lets OEMs develop wireless sensors and switches for building automation and heating, ventilation, and air conditioning. Dolphin modules are said to feature the industry's lowest-power sleep-mode current (200 nA) and consume one-tenth the power of conventional low-power modules.

EnOcean's technology is used by Illumra Controls in a keycard switch that saves energy in hotel rooms. It automates hotel-room energy consumption by disabling HVAC, lighting, and electrical loads in unoccupied rooms. The keycard can be used as a standard item or customized. It transmits signals to Illumra receivers attached to appliances and lights, activating them when a card is inserted and deactivating them when the card is removed. Seven code combinations are available for customizing the keycard, so it can be used not just by hotel guests, but also by hotel staff and management.

EnOcean's wireless energy harvesting concept is also finding its way into the automotive world. Austria's Sensor Dynamics AG expects to use EnOcean's transceiver circuit for batteryless tire-pressure management systems (TPMSs) in cars. Batteryless TPMSs have yet to take hold on a large scale, but the potential for use in millions of cars means many companies are working on the concept.

Mobile platforms can gain from energy harvesting as well. An example comes from MicroStrain Inc. which uses the piezoelectric effect to power inertial measurement systems, displacement transducers, and wireless sensing networks. Gyroscopic measurements gauge the angular position of moving platforms to stabilize cameras and other sensitive equipment. The firm also makes temperature-compensated differential variable-reluctance transducers that sense the proximity of metal targets.

AdaptivEnergy is yet another firm capitalizing on the piezoelectric effect. Its Joule-Thief dc power supplies harness energy from vibrations, impacts, and force. A demonstration kit consists of a power device, TI MSP430 microcontroller, CC2500 radio transmitter and receiver for 2.4GHz wireles data transmission, wireless sensor firmware, and a USB plug-and-play connection for energy harvesting demonstrations. The user-interface software acquires signals and profiles the power obtained from vibrations.

Electromagnetic harvesting is another way to harness energy from vibrations. The typical configuration consists of a spring-loaded magnet that moves inside a cylindrical coil. Magnet movement in response to vibration induces ac in the coil around the spring-mass resonant frequency to form a high-impedance ac power source. The ac is typically rectified and charges either a battery or an ultracapacitor.

The United Kingdom's Perpetuum Ltd. makes devices that harvest electromagnetic energy. One major use for the firm's technology is in monitoring motors in manufacturing plants by sensing vibration changes as a motor begins to degrade.

Perpetuum's energy harvesters handle electric motor applications where most vibrations are in a narrow band. They employ thermal compensation to maintain the correct resonator frequency over the full temperature range. They can also be optimized for vibrations over a wide band as in monitoring rail vehicles.

Lumedyne Technologies is another company investigating electromagnetic energy harvesting. It has developed proof-of-concept accelerometers using its V-Power technology that builds on developments at the U.S. Navy Space and Naval Warfare Systems Command. It features ultra-low levels of sensitivity with a signal-to-noise ratio of -115 dB and can produce about 40 mW/cc of acceleration. Lumedyne also is working on devices able to harvest kinetic energy from displacements of as little as a few microns. The company uses optical microelectromechanical technology for this task.

Developments in energy harvesting are also leading to developments in another area: supporting analog, power, and digital ICs, includes voltage regulators, voltage and current controllers, and sensors. According to the marketing research firm Gartner Inc., the IC voltage regulator segment of this market, mostly for computers and industrial applications, will grow at a compound annual growth rate of 3% through 2012, despite the present economic downturn.

These devices supplement energy harvesters. In many cases, they are optimized to accept low voltage and current. In some cases, they can even be powered directly from an energy-harvesting unit. Companies like Texas Instruments, National Semiconductor, Linear Technology, International Rectifier, Freescale Semiconductor, and Advanced Linear Devices are leading producers of analog ICs for energy harvesting. Some provide development kits. Even Intel plans to develop energy-harvesting RF sensors.

IC companies like Linear Technology, Freescale Semiconductor and Advanced Linear Devices provide power circuitry that operates from extremely low levels of scavenged energy and puts out voltages large enough to power other circuitry, including energy-harvesting modules and wireless sensors. An example is Linear Technology's LTC 3108 dc-dc converter chip that accepts 20-mV inputs from a thermoelectric generator. The chip's 2.2-V low-dropout output regulator can power an external microcontroller. The output is pin-selectable to one of four fixed voltages of 2.35, 3.3, 4.1 and 5 V, enough to power a wireless transmitter or sensor.

Freescale Semiconductor developed a mixed-signal chip that converts the output from a single solar cell starting as low as 320 mV, at claims of 82 to 90% efficiencies. The chip outputs four volts. Also in this category is an array of zero-threshold MOSFETs from Advanced Linear Devices. It accepts inputs of about 400 mV to produce a more useful four volts.

Developments in energy storage devices will have a large impact on macro-scale energy harvesting applications. There is a lot of research aimed at storing energy in super-small form factors such as thin films. For example, the MEC102 solid-state InfinEnergy micro power module from Infinite Power Solutions. The flexible and rechargeable thin-film power cell is said to outperform all other electrochemical energy storage devices with capacities up to 2.5 mAh from a 2.5-×-50.8-mm package that's 170-µm thick.

Key to the battery cell's performance are materials that give it a high energy density and let it to operate at ambient temperatures up to 85°C. It has a lithium-cobalt oxide cathode and a lithium-metal anode. A solid-state electrolyte made of lithium phosphorous oxynitride provides high Li-ion mobility.

On another front, Intel is developing a device that scavenges RF energy from the airwaves. Its Wireless Identification and Sensing Platform powers commercial off-the-shelf UHF RFID readers. It can pick up about 60 µW of RF energy, enough to drive a thermometer/hygrometer and its associated LCD, from a TV tower at a distance of 4.1 km.

The influence of MEMS

The benefits of energy scavenging are so appealing that sensor makers are starting to devise sensors specifically to work at super-low power levels. That is the case for an ultrasensitive inertial MEMS accelerometer platform recently developed by Hewlett-Packard Labs. It's 1,000 x more sensitive than high-volume commercial accelerometers used in automotive and consumer electronics items, yet is inexpensive and small. It uses MEMS fluidic technology borrowed from HP's inkjet printers. The sensor consumes less than 50 mW/axis and features an extremely low noise floor of 100 nG/√Hz. It senses from 0 to 25 Hz, extendable to 10 kHz.

The accelerometer won't be sold individually to end users - HP is looking for a partner that would produce a sensor/power-scavenger combo. “We plan to piggyback this sensor with other sensing elements and electronics, and partner with others to devise a wireless sensor systems,” explains Grant Pease, business development manager at HP's Technology Development Organization.

Nor would such modules be limited to just monitoring vibrations. “There are many other aspects to wireless sensing system besides the vibration our sensor offers. You also have stress and strains, temperature, transceiver circuitry, and power” he says. HP also sees roadway monitoring as a big potential application for the device and says it would be straightforward to make such sensors with more axes or bandwidth as specific applications require.

Another area where MEMS technology could team up with scavenged power is in HVAC, refrigeration and cooling, and automotive transmissions. Microstaq Inc. developed its Ventillum chip as a silicon replacement for solenoids in electromechanical expansion valves. “The valve allows the movement of tens and hundreds of liters of fluid, with nanometer and micrometer accuracy,” says Sandeep Kumar, Microstaq CEO. “This truly ground-breaking technology addresses the needs of those using expansion valves to control large amounts of fluid and will have huge ramifications.” The company claims the reduction in power drain this chip makes possible could reduce global energy consumption by more than 1.2 billion barrels of oil per year.

More info

AdaptivEnergy, Hampton Va., www.adaptivenergy.com/

Advanced Ceramics Corp., Wakefield, Mass., www.ferroceramic.com

Advanced Linear Devices, Sunnyvale, Calif., www.aldinc.com

Darnell Group, Corona, Calif., www.darnell.com/

EnOcean Inc., Boston, Mass., www.enocean.com/

Freescale Semiconductor, Austin, Tex., www.freescale.com/

Gartner Inc., Stamford, Conn., www.gartner.com/technology/home.jsp

Hewlett-Packard Labs, Palo Alto, Calif., www.hpl.hp.com/

Illumra Controls, Orem, Utah, www.illumra.com/

Infinite Power Solutions, Littleton, Colo., www.infinitepowersolutions.com/

EngineeringTV.com coverage of Infinite Power Solutions development platform, http://tinyurl.com/82f4mt

Intel WISP work, www.intel.com/pressroom/kits/events/idfspr_2006/Tech-a-palooza.pdf

International Rectifier, El Segundo, Calif., www.irf.com/indexnsw.html

Linear Technology, Milpitas, Calif., www.linear.com/

Lumedyne Technologies, San Diego, Calif., www.lumedynetechnologies.com/

Measurement Specialties Inc., Hampton, Va., www.meas-spec.com/

MicroStrain Inc., Williston, Vt., www.microstrain.com/

Microstaq Inc., Austin, Tex., www.microstaq.com/

National Semiconductor Corp., www.national.com/analog

Perpetuum Ltd., U.K., www.perpetuum.com/

Sensor Dynamics AG, Austria, http://tinyurl.com/ygyawjd

Texas Instruments Inc., Dallas, Tex., ti.com

About the Author

Roger Allan

Roger Allan is an electronics journalism veteran, and served as Electronic Design's Executive Editor for 15 of those years. He has covered just about every technology beat from semiconductors, components, packaging and power devices, to communications, test and measurement, automotive electronics, robotics, medical electronics, military electronics, robotics, and industrial electronics. His specialties include MEMS and nanoelectronics technologies. He is a contributor to the McGraw Hill Annual Encyclopedia of Science and Technology. He is also a Life Senior Member of the IEEE and holds a BSEE from New York University's School of Engineering and Science. Roger has worked for major electronics magazines besides Electronic Design, including the IEEE Spectrum, Electronics, EDN, Electronic Products, and the British New Scientist. He also has working experience in the electronics industry as a design engineer in filters, power supplies and control systems.

After his retirement from Electronic Design Magazine, He has been extensively contributing articles for Penton’s Electronic Design, Power Electronics Technology, Energy Efficiency and Technology (EE&T) and Microwaves RF Magazine, covering all of the aforementioned electronics segments as well as energy efficiency, harvesting and related technologies. He has also contributed articles to other electronics technology magazines worldwide.

He is a “jack of all trades and a master in leading-edge technologies” like MEMS, nanolectronics, autonomous vehicles, artificial intelligence, military electronics, biometrics, implantable medical devices, and energy harvesting and related technologies.